High-strength shrinkage-reducing cement mortar doped with steel fibers and floating beads and preparation method of high-strength shrinkage-reducing cement mortar

A steel fiber, high-strength technology, applied in the field of high-strength shrinkage-reducing cement mortar and its preparation, can solve the problems of accelerated crack development, entry, and mechanical properties of cement mortar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of high-strength anti-cracking cement mortar of the present invention comprises the following steps:

[0024] Weigh water, cement, silica fume, metakaolin, steel fiber, floating beads, and quartz sand. Stir the cement, silica fume, and metakaolin evenly, then add water and water reducer, stir until the cement mortar is thick, and then continue to add saturated perforated floating beads. Stir for 2 minutes and finally disperse and add steel fibers and stir until viscous and laitance-free, and the high-strength shrinkage-reducing cement mortar is obtained.

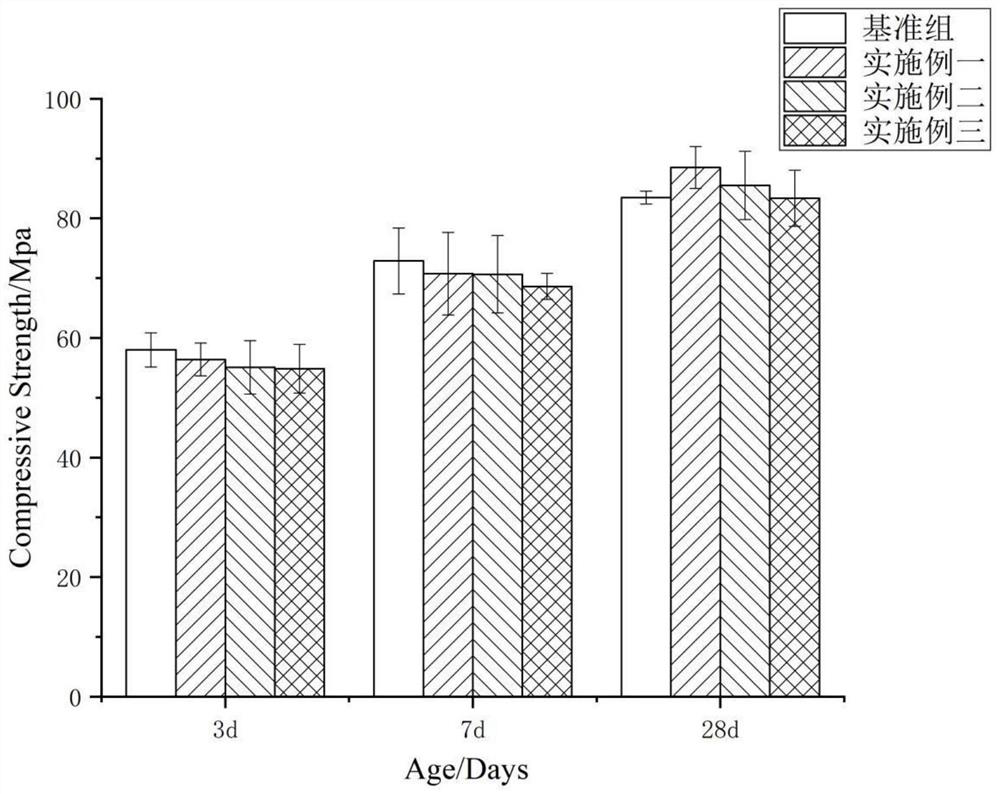

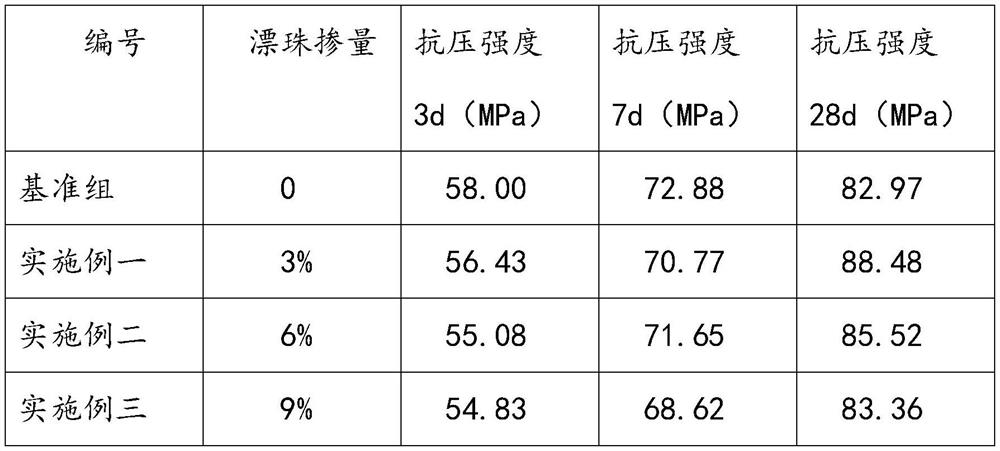

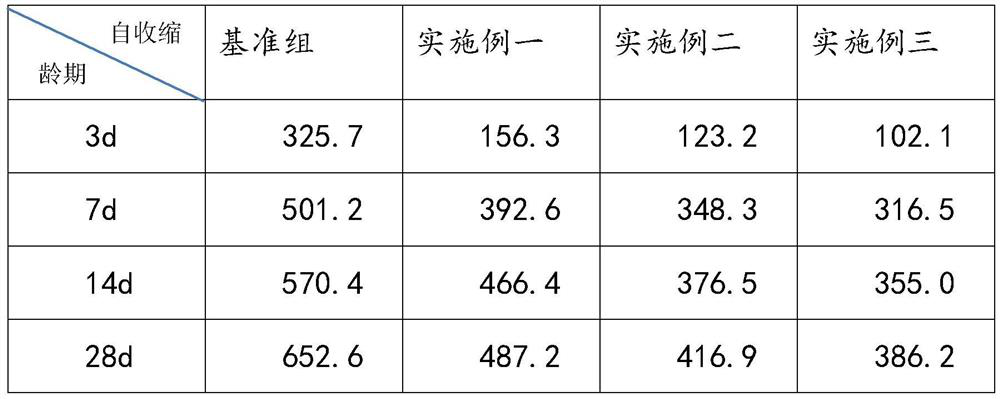

Embodiment 1

[0026] The high-strength shrinkage-reducing cement mortar described in the present invention is prepared from water, cement, silicon powder, metakaolin, quartz sand, water-saturated floating beads, steel fibers, and polycarboxylic acid high-efficiency water reducer. The mass ratio of water, cement, silica fume, metakaolin, quartz sand, and saturated floating beads is: 1042:4168:521:521:3600:286.

[0027] The dosage of the water reducing agent is 3% of the cementitious material, and the cementitious material includes cement, silica fume and metakaolin. The steel fiber volume dosage is 3%.

[0028] The cement is P·O52.5 ordinary Portland cement.

[0029] The purity of silicon powder is greater than 99.96%, and the apparent density is 2000kg / m 3 .

[0030] The fineness modulus of metakaolin is 1250 mesh, and the activity index is greater than 110.

[0031] The proportion of quartz sand is to mix 20-40 mesh, 40-60 mesh, 60-80 mesh, and 80-120 mesh quartz sand according to the ...

Embodiment 2

[0044] The high-strength shrinkage-reducing cement mortar described in the present invention is prepared from water, cement, silicon powder, metakaolin, quartz sand, water-saturated floating beads, steel fibers, and polycarboxylic acid high-efficiency water reducer. The mass ratio of water, cement, silica fume, metakaolin, quartz sand, and saturated floating beads is: 1042:4168:521:521:3200:574.

[0045] The dosage of the water reducing agent is 3% of the cementitious material, and the cementitious material includes cement, silica fume and metakaolin. The steel fiber volume dosage is 3%.

[0046]Repeat the experimental operation of Example 1 to obtain the cement mortar mixture. Put the cement mortar mixture into the mold, put it on the vibrating table for vibration, and install the mold twice. After the second mold loading, smooth it on the vibrating table until the plane is smooth, and remove the mold after 24 hours. Then put it into the curing room for standard curing, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com