Method for catalytically synthesizing doxycycline dehydrated substance by using ionic liquid and zeolite at normal temperature

A technology of ionic liquid and doxycycline, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., to achieve the effect of less by-products, mild reaction conditions and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for catalytically synthesizing doxycycline dehydrate with normal temperature ionic liquid and zeolite, comprising the following steps:

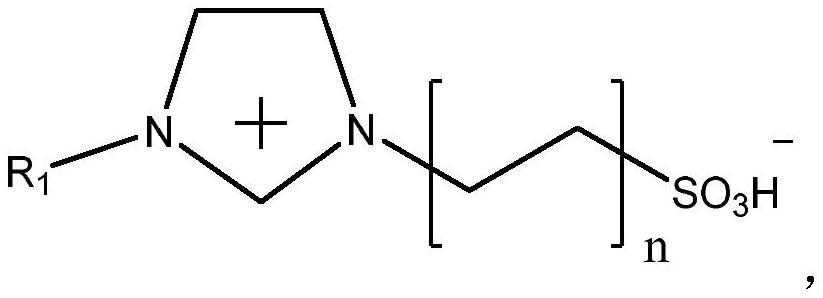

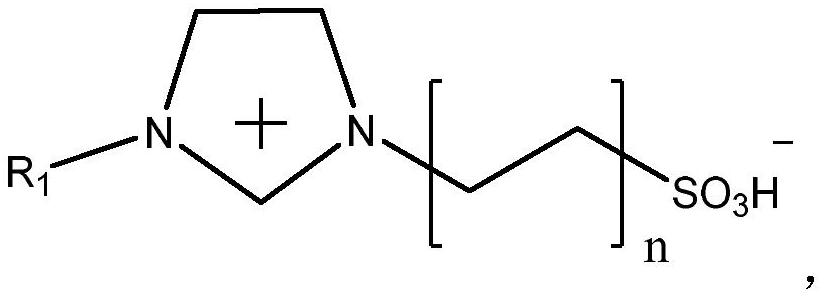

[0025] a) Weigh 43.6 g of 3-sulfobutyl-1-methylimidazolium, slowly add 30.2 g of trifluoromethanesulfonic acid, stir thoroughly for 1 hour, and obtain 73.9 g of viscous liquid;

[0026] Immerse 5g of H-beta zeolite with 10mL of 0.1mol / L disodium citrate solution, stir for 5 hours under the condition of heating in a water bath at 70°C, and repeat twice after suction filtration to obtain about 5g of citrate-modified H-beta zeolite ; 50 mg of citrate-modified H-beta zeolite was added to 50 mL of 3-sulfobutyl-1-isopropylimidazolium-trifluoromethanesulfonic acid ionic liquid at 20°C and stirred for 5 min to form Ionic liquid reaction system;

[0027] b) Put 25 g of dried oxytetracycline into the above-mentioned ionic liquid reaction system at 20°C, stir to dissolve, keep the temperature at 23°C for 70 minutes, and recover the zeol...

Embodiment 2

[0031] A method for catalytically synthesizing doxycycline dehydrate with normal temperature ionic liquid and zeolite, comprising the following steps:

[0032] a) Weigh 1.85 kg of 3-sulfobutyl-1-ethylimidazolium, slowly add 0.77 kg of methanesulfonic acid, and fully stir for one hour to obtain 2.64 kg of viscous liquid;

[0033] Immerse 100g of H-beta zeolite with 0.2L of 0.15mol / L potassium dihydrogen phosphate solution, stir for 5 hours under the condition of heating in a water bath at 80°C, and repeat twice after suction filtration to obtain about 100g of phosphate-modified H-beta zeolite ; Add 20g of phosphate-modified H-beta zeolite to 2L of 3-sulfobutyl-1-ethylimidazolium-trifluoromethanesulfonic acid ionic liquid at 20°C and stir for 10min to form an ionic liquid reaction system;

[0034] b) Put 1kg of dried oxytetracycline into the above-mentioned ionic liquid reaction system at 20°C, stir and dissolve, keep the temperature at 23°C for 70 minutes, and recover the zeol...

Embodiment 3

[0038] A method for catalytically synthesizing doxycycline dehydrate with normal temperature ionic liquid and zeolite, comprising the following steps:

[0039] a) Weigh 984.4 kg of 3-sulfobutyl-1-isopropylimidazolium, slowly add 600.3 kg of trifluoromethanesulfonic acid, and stir thoroughly for 1 hour to obtain 1585.4 kg of viscous liquid;

[0040] Immerse 1kg of H-beta zeolite with 10L of 0.1mol / L potassium dihydrogen phosphate solution, stir for 5h under the condition of heating in a water bath at 70°C, and repeat twice after suction filtration to obtain about 1kg of phosphate-modified H-beta zeolite; Add 1kg of phosphate-modified H-beta zeolite to 1000L 3-sulfobutyl-1-isopropylimidazolium-trifluoromethanesulfonic acid ionic liquid at 20°C, stir for 30 minutes, and form an ionic liquid reaction system;

[0041]b) Put 500 kg of dried oxytetracycline into the above-mentioned ionic liquid reaction system at 20° C., stir and dissolve, and keep the reaction at 23° C. for 70 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com