Method for photocatalytic synthesis of azobenzene oxide

A technology of azobenzene oxide and photocatalysis, which is applied in organic chemistry and other fields, and can solve problems such as high cost and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

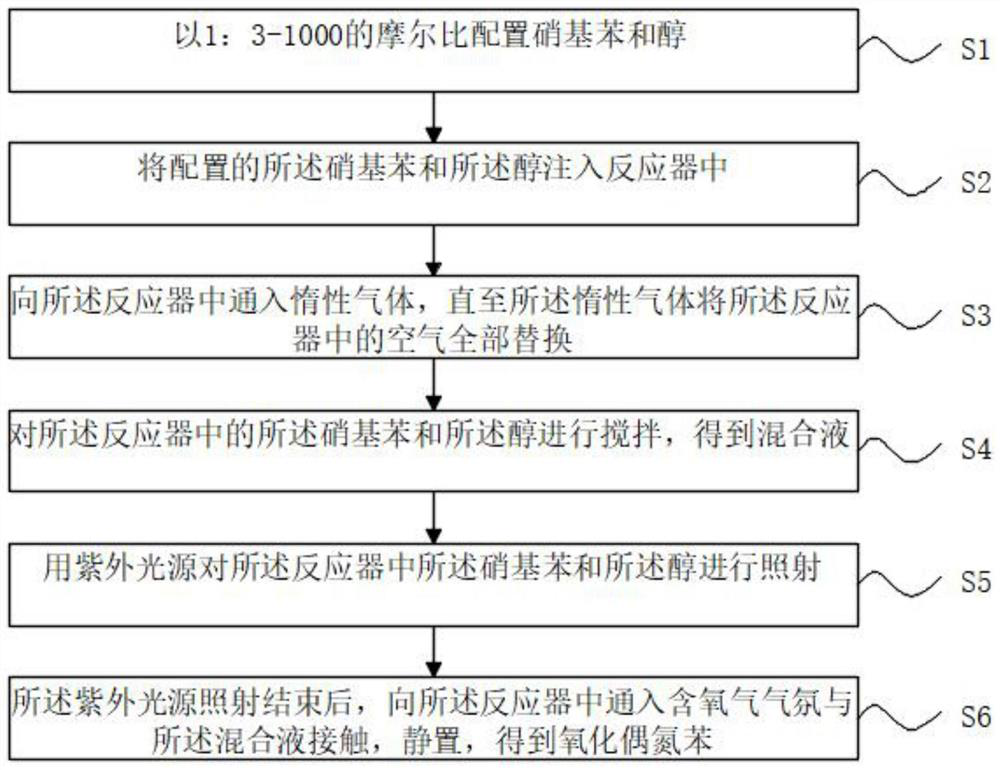

Method used

Image

Examples

Embodiment 1

[0040] Measure 10uL of the nitrobenzene and 25mL of the isopropanol-water solution (volume concentration 60%) in the reactor with a stopper, feed Ar for 5min to replace the air in the reactor, and use the 300W of the Irradiated by the xenon lamp light source, stirred for 3 hours, and the reaction temperature was 66°C. After the light was finished, air was blown in, and the azobenzene oxide was prepared at 60°C for 5 hours. The conversion rate of the nitrobenzene was 98.0%. The yield of azobenzene oxide is 82.7%.

Embodiment 2

[0042] Measure 10uL of the nitrobenzene and 25mL of the isopropanol-water solution (volume concentration 60%) in the reactor with a stopper, feed Ar for 5min to replace the air in the reactor, and use the 300W of the Irradiate with the xenon lamp light source, stir for 2 hours, and the reaction temperature is 58°C. After the light is finished, open the plug of the reactor, let the air enter the reactor, then plug the plug tightly, and let it stand at room temperature for 14 days to prepare the azo oxide. Benzene, the conversion rate of nitrobenzene is 93.5%, and the yield of azobenzene oxide is 86.8%.

Embodiment 3

[0044] Measure 10uL of the nitrobenzene and 25mL of the isopropanol-water solution (volume concentration 60%) in the reactor with a stopper, feed Ar for 5min to replace the air in the reactor, and use the 300W of the The xenon light source is irradiated, stirred for 2 hours, and the reaction temperature is 40°C. After the light is finished, the plug of the reactor is opened to allow air to enter the reactor, and then the plug is tightly closed, and the oxidized dioxane can be obtained by standing at 60°C for 6 hours. Nitrobenzene, the conversion rate of nitrobenzene is 79.8%, and the yield of azobenzene is 66.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com