Phase change heat storage curing device for concrete structure in cold environment and implementation method of phase change heat storage curing device

A concrete structure and phase change heat storage technology, applied in the field of civil engineering, can solve problems such as time and space differences in solar energy resources, difficulty in judging the energy requirements of phase change materials for solar energy resources, and uneven distribution of solar energy in time and space, so as to reduce carbon Emissions and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

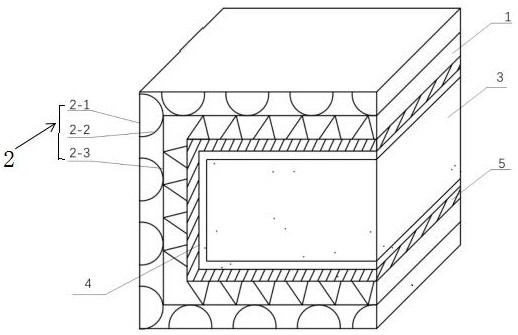

[0066] Example 1: Combining figure 1 To illustrate this embodiment, the one-way light-transmitting thermal insulation layer 2 in this embodiment is a multi-layer structure, and airbags are formed between each layer of the multi-layer structure to achieve a thermal insulation effect. The one-way light-transmissive thermal insulation layer 2 is supported by the interlayer The structure 1 is covered on the concrete formwork 4 as a whole, and the energy storage layer 5 is closely attached to the sunny side of the concrete; the shady side of the concrete is directly insulated by the interlayer support structure 1 and the one-way light-transmitting insulation layer 2, and no storage layer is set on the shady side. The interlayer support structure directly falls on the concrete formwork; the interlayer support structure 1 is a lightweight plastic cage or wooden cage, which can support the one-way light-transmitting insulation layer, which can ensure the support of one-way light trans...

Embodiment 2

[0067] Embodiment 2: the present embodiment is the further limitation of embodiment 1, and the inner and outer surfaces of unidirectional light-transmitting thermal insulation layer 2 adopts light-transmitting plastic film, and the inboard of light-transmitting plastic film on outer surface is provided with magnetron sputtering film, magnetron sputtering The film protrudes toward the concrete side to form an airbag structure to concentrate light, and only allows sunlight to pass through in one direction. The thickness of the magnetron sputtering film on the shady side and the sunny side is different. For the magnetron sputtering film on the positive side, Its one-way light transmittance should be more than 70% to ensure that sunlight can pass through the one-way light-transmitting insulation layer 2, and the infrared reflectance of the magnetron sputtering film on the shade side should be above 60% to ensure one-way light transmission. The heat insulation effect of the light in...

Embodiment 3

[0069] Embodiment 3: The maintenance device in this embodiment includes a one-way light-transmitting thermal insulation layer 2, an interlayer support structure 1, and an energy storage layer 5. The three are stacked sequentially from the outside to the inside, and the three form an integrated flexible coil that can be rolled up. Structure, after coiling and connection, it can form a three-dimensional structure with a cavity inside. After coiling, a movable connection port is set for the unclosed position, such as unclosed by bonding, sticky connection, buckle connection, zipper or pin connection. The location should be sealed. Before sealing, the components to be maintained, such as equipment and concrete, can be placed in the cavity to realize the complete wrapping of the components to be maintained. During the placement process, it is necessary to ensure that there is an energy storage layer on the sunny side. After placement, the unsealed The position is closed, and the int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com