Ultrahigh-temperature polymer polyethylene lining pipe

A technology of high molecular polyethylene and polyethylene pipes, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve problems such as misalignment of inner lining and outer pipe, high oil pressure, affecting flow rate, etc., to prevent Softening shrinkage, low cost, and enhanced product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

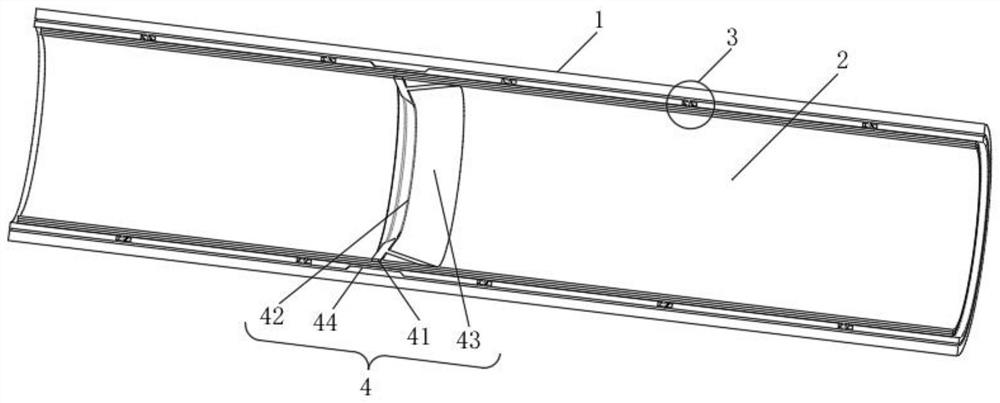

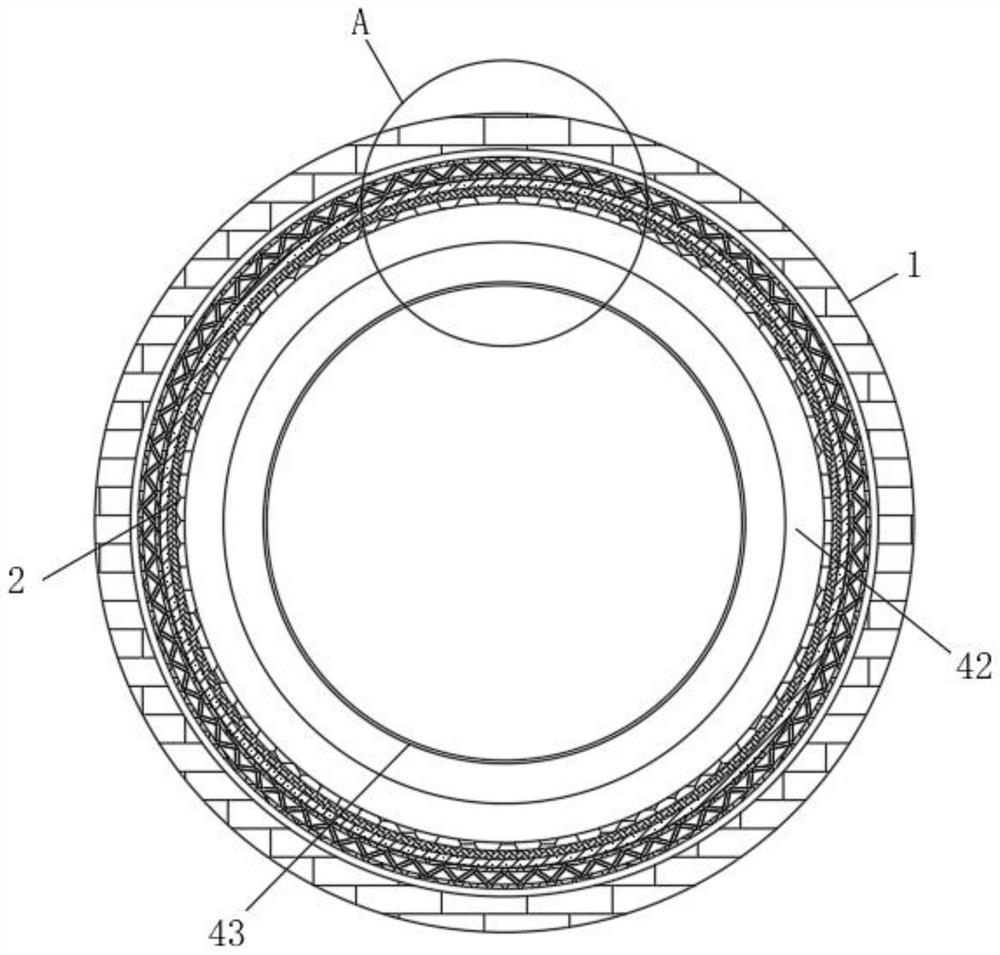

[0046] see Figure 1-4 , an ultra-high temperature polymer polyethylene lined pipe, comprising an outer pipe 1, the inner side of the outer pipe 1 is inserted with a lined pipe 2;

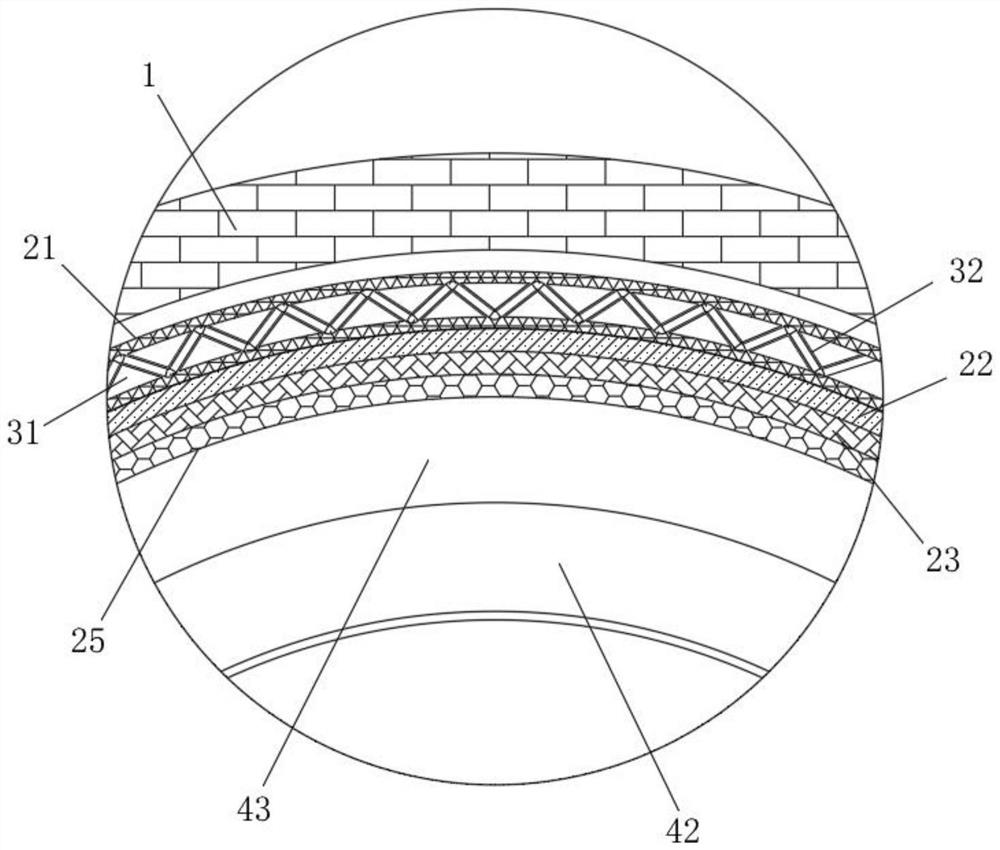

[0047] The lining pipe 2 includes from the outside to the inside: a rubber tube layer 21, a glass fiber tube layer 22, a PE tube layer 23, a polyethylene tube layer 24, and the inner side of the polyethylene tube layer 24 is coated with a silicon carbide coating 25;

[0048] Both the PE pipe layer 23 and the polyethylene pipe layer 24 are heat-treated to increase internal stress;

[0049] Glass crystals are mixed into the PE pipe layer 23 to improve the toughness of the PE pipe layer 23 .

[0050] By using the composite lining pipe 2, the rubber pipe layer 21 increases the connection strength between the lining pipe 2 and the outer pipe 1, the glass fiber pipe layer 22 and the PE pipe layer 23 improve the toughness and high temperature resistance of the lining pipe 2, The silicon carbide coating ...

Embodiment 2

[0052] see Figure 1-4 , an ultra-high temperature polymer polyethylene lined pipe, comprising an outer pipe 1, the inner side of the outer pipe 1 is inserted with a lined pipe 2;

[0053] The lining pipe 2 includes from the outside to the inside: a rubber tube layer 21, a glass fiber tube layer 22, a PE tube layer 23, a polyethylene tube layer 24, and the inner side of the polyethylene tube layer 24 is coated with a silicon carbide coating 25;

[0054] The supporting mechanism 3 includes a supporting inner cavity 31 provided in the rubber tube layer 21 , and the supporting inner cavity 31 is fixedly connected with a supporting frame 32 .

[0055] The supporting inner chambers 31 are distributed at intervals, and the interval distance is inversely proportional to the heat fusion ratio of the lining pipe 2;

[0056] The thermal fusion ratio is the ratio of temperature rise and curvature of a one-meter-long lining pipe 2 fixed at both ends;

[0057] In this way, the easier the...

Embodiment 3

[0068] see Figure 1-4 , an ultra-high temperature polymer polyethylene lined pipe, comprising an outer pipe 1, the inner side of the outer pipe 1 is inserted with a lined pipe 2;

[0069] The lining pipe 2 includes from the outside to the inside: a rubber tube layer 21, a glass fiber tube layer 22, a PE tube layer 23, a polyethylene tube layer 24, and the inner side of the polyethylene tube layer 24 is coated with a silicon carbide coating 25;

[0070] The supporting mechanism 3 includes a supporting inner cavity 31 provided in the rubber tube layer 21 , and the supporting inner cavity 31 is fixedly connected with a supporting frame 32 .

[0071] The supporting inner chambers 31 are distributed at intervals, and the interval distance is inversely proportional to the heat fusion ratio of the lining pipe 2;

[0072] The thermal fusion ratio is the ratio of temperature rise and curvature of a one-meter-long lining pipe 2 fixed at both ends;

[0073] In this way, the easier the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com