Magnetic circuit focusing sharing type multi-channel online detection system and method

A detection system and a shared technology, applied in the direction of material magnetic variables, etc., can solve the problems of inability to detect sensitivity and full coverage of detection, the overall function has not been fully explored, and the detection effect of composite methods has been reduced, so as to improve detection sensitivity , compact structure, and improved detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

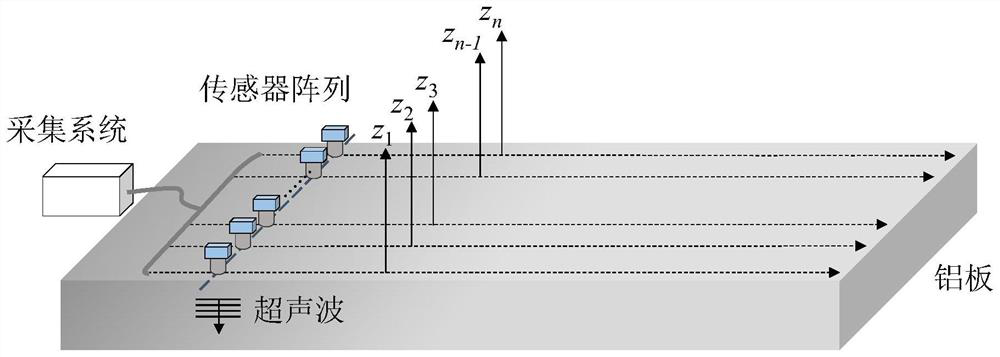

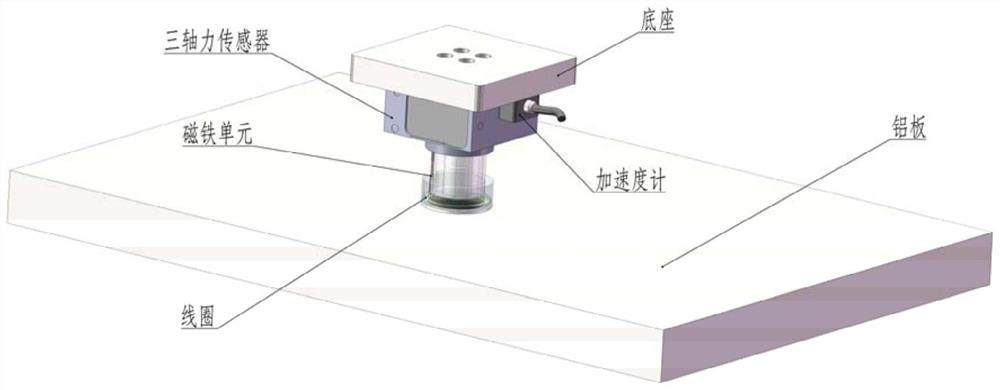

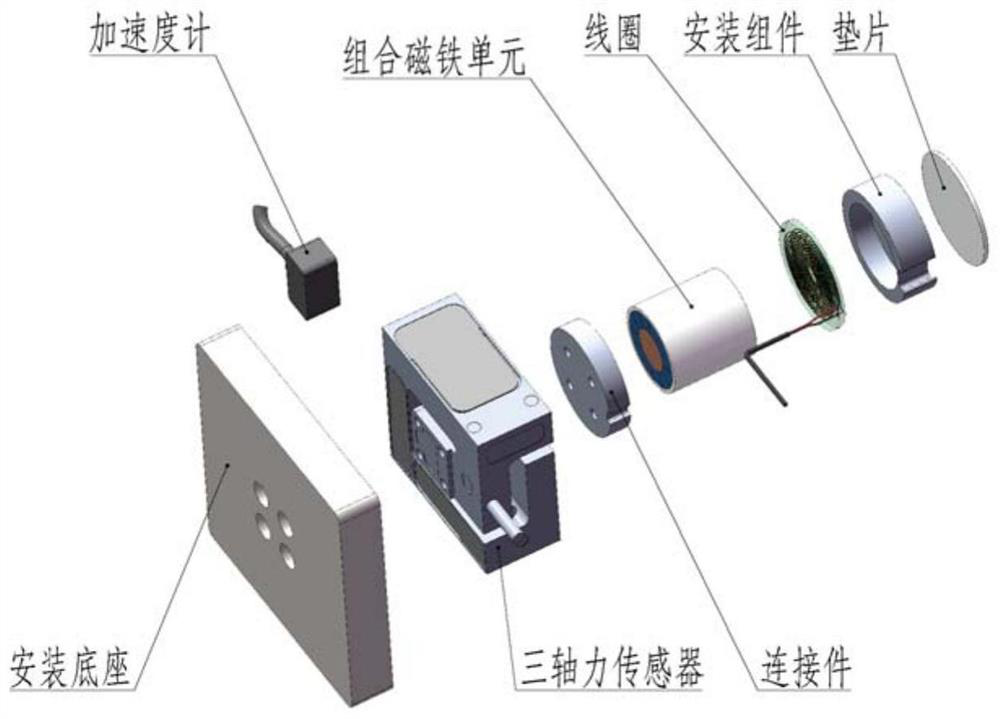

[0038] A magnetic circuit shared multi-channel online detection system, the schematic diagram of the detection layout is shown in figure 1, including a sensor array composed of multiple probes, a tomographic detection module, and a defect signal alarm module. The probe is a magnetic circuit focusing shared probe. The structure diagram of the probe is shown in figure 2 , the probe assembly diagram is shown in image 3 , which includes gaskets, mounting components, AC excitation coils, combined magnet units, connectors, three-axis force sensors, accelerometers and mounting bases assembled together from bottom to top, wherein,

[0039] The installation component is used to cover the gasket under the coil, and fix the coil under the combined magnet unit;

[0040] The combined magnet unit is used to provide a focused m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com