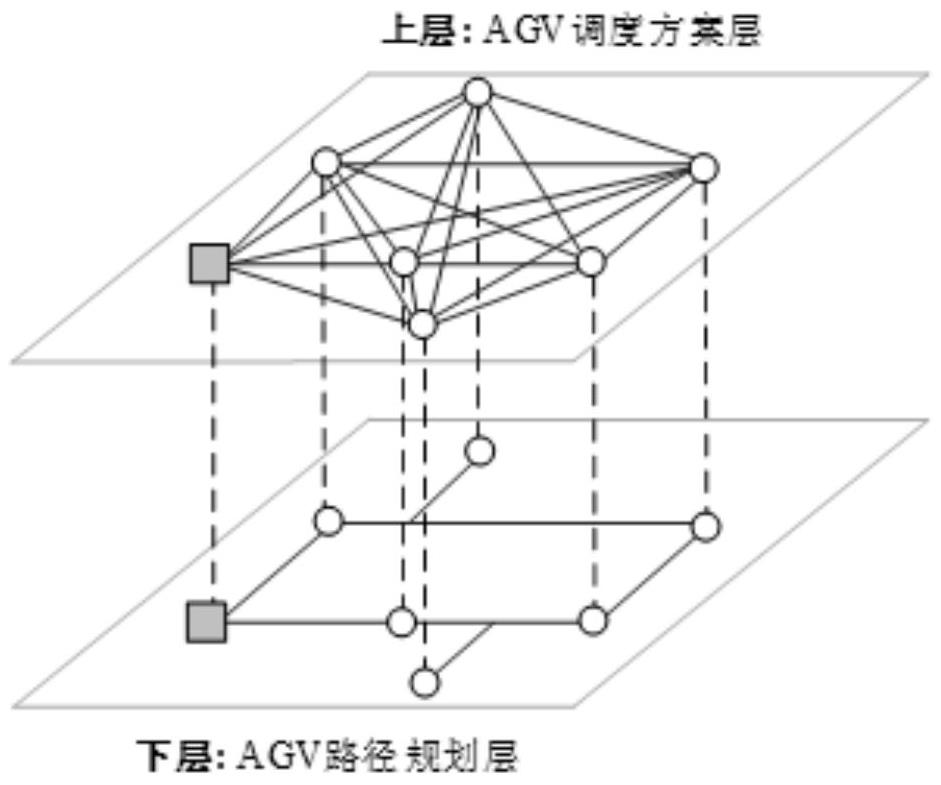

AGV operation optimization system and method based on double-layer space-time network structure

A technology of operation optimization and operation system, applied in the direction of comprehensive factory control, electric/hybrid, comprehensive factory control, etc., can solve problems such as short completion time, and achieve the effect of improving automation rate, expanding space, and clear control logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Such as Figure 6 As shown, this embodiment provides an AGV operation optimization method based on a double-layer space-time network structure. The optimization method is implemented in the pycharm software by using the python programming language, and specifically includes the following steps:

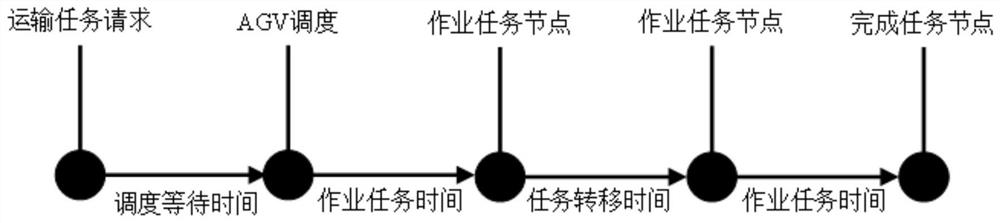

[0036] Step 1: The production execution master control machine imports the production tasks, and the production execution master control machine selects the order with the highest priority from the current order list as the pending task. If the orders in the order list have the same priority, select the order placement time The earliest order is regarded as a pending task; the master production execution control machine sends the pending transshipment tasks to the AGV scheduling equipment;

[0037] Step 2: The AGV scheduling equipment judges whether there are idle AGV vehicles available at the current moment, and dispatches the idle AGV vehicles to the workstation area to pick ...

Embodiment 2

[0050] Such as Figure 5 As shown, a kind of AGV operation optimization method based on the double-layer space-time network structure of this embodiment, the required number of warehouses is 4, the starting point of the task is 1123, and the end point of the task is 1707. After the AGV completes the task, it needs to return to the position of 1123; specifically includes Follow the steps below:

[0051] Step 1: Call the idle AGV closest to the task point, and use the Dijkstra algorithm to find the shortest path for the AGV to execute the task from its current point to the task point 1123.

[0052] Step 2: The AGV arrives at the designated pick-up point 1123, picks up the goods, and continues to use the Dijkstra algorithm to find the shortest path of the AGV from the task starting point 1123 to the delivery point 1707.

[0053] Step 3: After the AGV completes the outbound task, the Dijkstra algorithm is used to find the shortest path for the AGV to execute the task from the out...

Embodiment 3

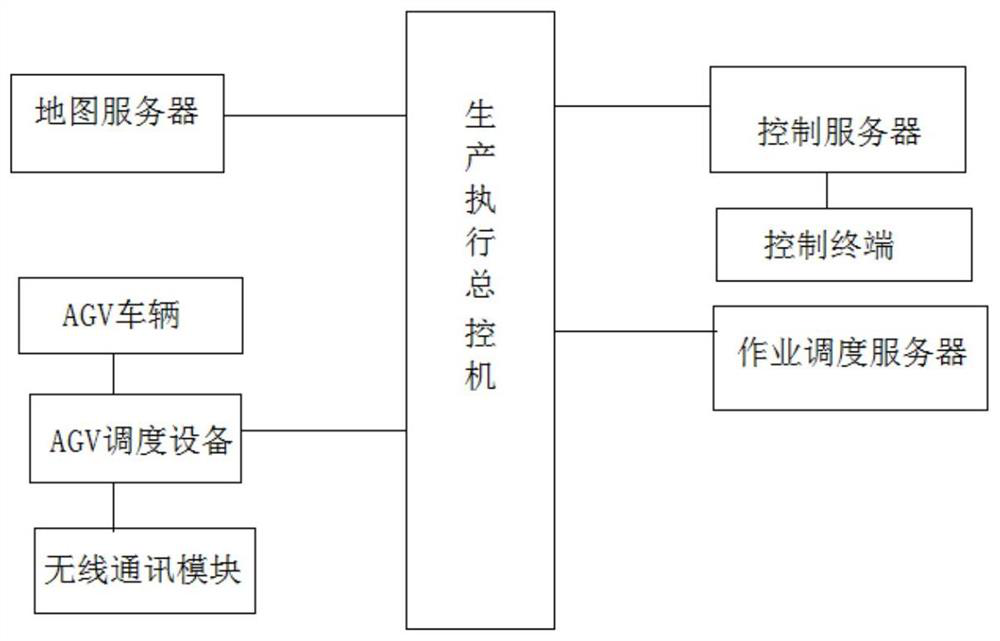

[0056] Such as figure 1 As shown, this embodiment provides an AGV operating system based on a double-layer space-time network structure, including a production execution master control machine, an AGV scheduling device, at least one AGV vehicle, a station master control machine, a job scheduling server, and a control server ; The network between the production execution master control machine, the AGV scheduling equipment, the job scheduling server and the control server is connected to each other, and the AGV scheduling equipment is connected to the AGV vehicle;

[0057] The control server is used to receive and issue control instructions;

[0058] The job scheduling server is used to form and issue job scheduling instructions.

[0059] It also includes a control terminal connected to the control server, through which the control terminal can input or load multi-dimensional scheduling record information to the control server; through the control terminal, a job scheduling ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com