Method for producing r-t-b sintered magnet

A technology of sintered magnets and manufacturing methods, applied in the direction of inductance/transformer/magnet manufacturing, manufacturing tools, magnetic objects, etc., can solve the problems of heavy processing load, long processing time, unavoidable, etc., and achieve manufacturing cost and mass production excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

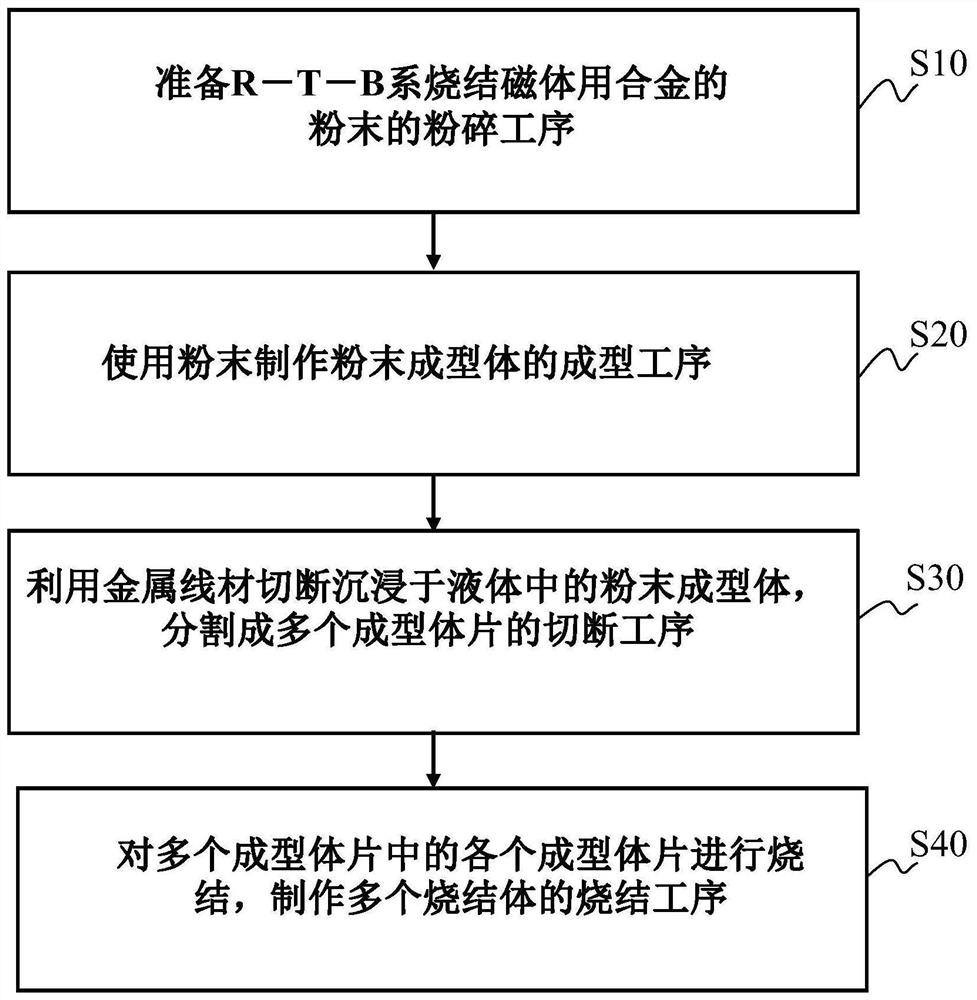

[0039] Hereinafter, an embodiment of the method for producing the R-TB based sintered magnet of the present invention will be described. Such as figure 1 As shown in the flow chart of the present embodiment, the manufacturing method of the R-TB system sintered magnet includes:

[0040] Prepare an alloy for R-T-B system sintered magnets (R is a rare earth element and must contain at least one selected from Nd, Pr and Ce, T is at least one transition metal and must contain Fe, and B is boron) The pulverizing process (S10) of the powder;

[0041] A forming process (S20) of producing a powder compact using powder;

[0042] Cutting the powder compact and dividing it into a plurality of compact pieces (S30);

[0043] sintering each of the plurality of molded body sheets to produce a plurality of sintered bodies (S40),

[0044] The cutting process ( S30 ) includes a step of cutting the above-mentioned powder compact immersed in the liquid by a traveling metal wire.

[0045] Acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com