Formula and preparation process of Mitoq anti-oxidation hard capsule

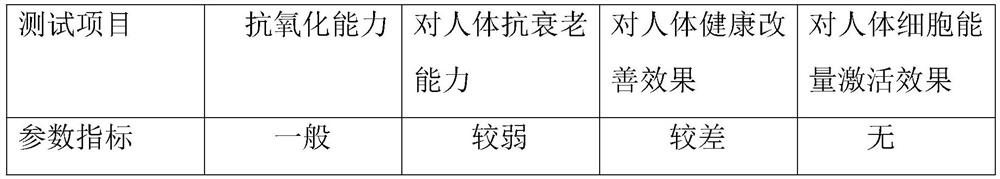

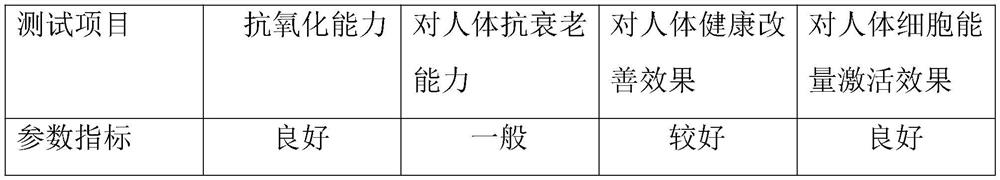

A preparation process and technology for hard capsules, applied in the field of Mitoq antioxidant hard capsule formulation and preparation technology, can solve the problems of weak antioxidant capacity, inability to effectively scavenge free radicals, poor anti-aging capacity, etc., so as to reduce oxidative stress damage , improve long-term health, improve anti-aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The Mitoq antioxidant hard capsule formula includes the following raw materials and their weight fractions: 10 mg parts by mass of Mitoq; 100 mg parts by mass of vitamin E; 40 mg parts by mass of astaxanthin; and 40 mg parts by mass of microcrystalline cellulose.

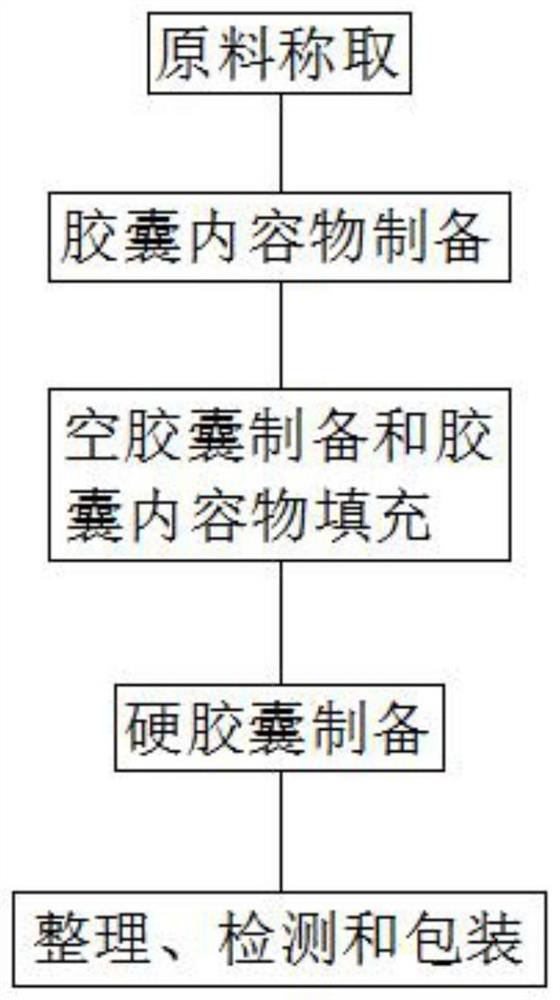

[0039] The preparation steps are as follows:

[0040] a. taking the above-mentioned raw materials according to parts by weight;

[0041] b. After step a is completed, put Mitoq, vitamin E, astaxanthin and microcrystalline cellulose into the mixer and mix evenly to prepare the contents of the capsule;

[0042] c. After step b is completed, put the raw materials of the empty capsules into the mixing machine for mixing, and then process the mixed raw materials through sol, dipping in glue, drying, shelling, cutting and finishing to make empty capsules, and then Fill the contents of the capsule into half of the empty capsule, and then nest the half of the empty capsule with the filled empty capsule;

[0043] d....

Embodiment 2

[0046] The Mitoq antioxidant hard capsule formula includes the following raw materials and their weight fractions: 20 mg parts by mass of Mitoq; 150 mg parts by mass of vitamin E; 50 mg parts by mass of astaxanthin; and 50 mg parts by mass of microcrystalline cellulose.

[0047] The preparation steps are as follows:

[0048] a. taking the above-mentioned raw materials according to parts by weight;

[0049] b. After step a is completed, put Mitoq, vitamin E, astaxanthin and microcrystalline cellulose into the mixer and mix evenly to prepare the contents of the capsule;

[0050] c. After step b is completed, put the raw materials of the empty capsules into the mixing machine for mixing, and then process the mixed raw materials through sol, dipping in glue, drying, shelling, cutting and finishing to make empty capsules, and then Fill the contents of the capsule into half of the empty capsule, and then nest the half of the empty capsule with the filled empty capsule;

[0051] d....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com