Advanced oxidation treatment method and equipment for phosphorus-containing flame retardant wastewater

An advanced oxidation and treatment method technology, applied in the field of water treatment, can solve the problems of uneconomical operation, high current density, high treatment cost, etc., and achieve the effects of low waste water treatment cost, energy saving and treatment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

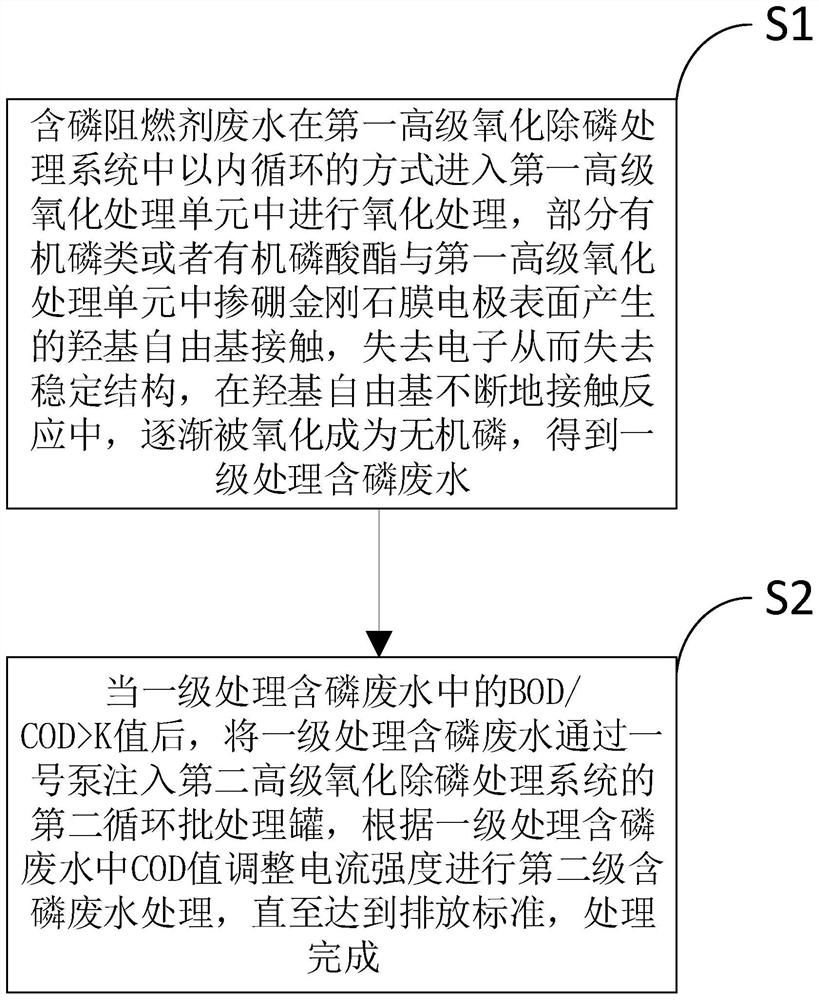

[0042] Such as figure 1 Shown, a kind of advanced oxidation treatment method of phosphorus flame retardant waste water, comprises the following steps:

[0043] S1. First-level phosphorus-containing wastewater treatment: phosphorus-containing flame retardant wastewater enters the first advanced oxidation treatment unit 13 for oxidation treatment in the first advanced oxidation phosphorus removal treatment system 1 through internal circulation, and some organic phosphorus or organic Phosphate ester contacts with the hydroxyl radicals generated on the surface of the boron-doped diamond membrane electrode in the first advanced oxidation treatment unit 13, and loses electrons and thus loses its stable structure. During the continuous contact reaction of hydroxyl radicals, it is gradually oxidized into inorganic phosphorus, and a Level treatment of phosphorus-containing wastewater;

[0044] The current density in the first advanced oxidation treatment unit 13 is 1000-2000 amps / squa...

Embodiment 2

[0052] Such as figure 1 Shown, a kind of advanced oxidation treatment method of phosphorus flame retardant waste water, comprises the following steps:

[0053] The boron-doped diamond film operates in the first advanced oxidation treatment unit 13, and the waste water enters the first advanced oxidation treatment unit 13 in an internal circulation manner in the first circulation batch tank 11. Organic phosphorus or organic phosphate and boron-doped diamond film The hydroxyl radicals generated on the electrode surface are fully contacted, their electrons are taken away, and their stable structure is lost. During the continuous contact reaction of hydroxyl radicals, they are gradually oxidized into inorganic phosphorus.

[0054] The first advanced oxidation treatment unit 13 of the boron-doped diamond film is fully automatic, and is driven by the No. 1 pump 12 to realize circulation treatment;

[0055] The boron-doped diamond film first advanced oxidation treatment unit 13 will...

Embodiment 3

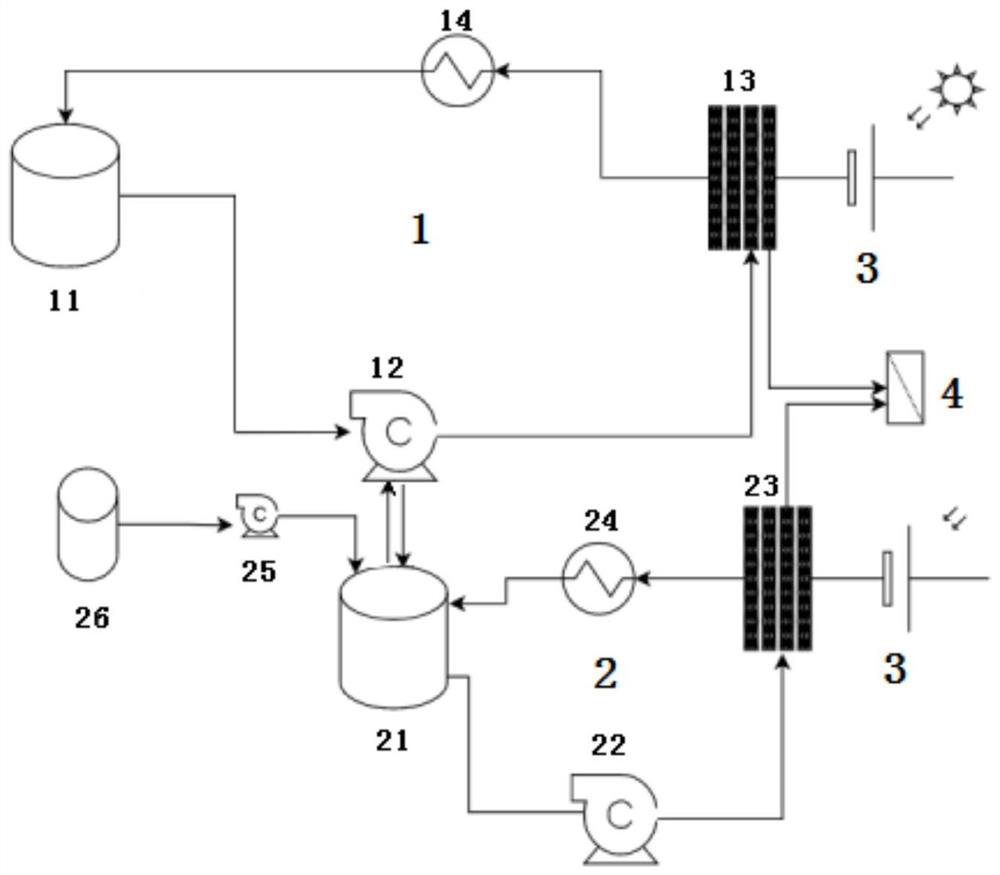

[0065] Such as figure 2 As shown, an advanced oxidation treatment equipment for phosphorus-containing flame retardant wastewater includes a connected first advanced oxidation phosphorus removal treatment system 1, a second advanced oxidation phosphorus removal treatment system 2, and the first advanced oxidation phosphorus removal treatment system 1 , The solar power supply system 3 and the tail gas purification system 4 connected to the second advanced oxidation phosphorus removal treatment system 2;

[0066] The first advanced oxidation phosphorus removal treatment system 1 is used for primary advanced oxidation treatment of phosphorus-containing wastewater, and the second advanced oxidation phosphorus removal treatment system 2 is used for secondary advanced oxidation treatment of the effluent of the first advanced oxidation phosphorus removal treatment system 1 deal with;

[0067] The first advanced oxidation dephosphorization treatment system 1 includes a first circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com