Preparation method and application of stabilized circulating filler

A stable and inner core technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water aeration, etc., can solve the problems of poor biofilm adhesion rate, easy clogging, easy aging, etc., to achieve stable adhesion, Anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

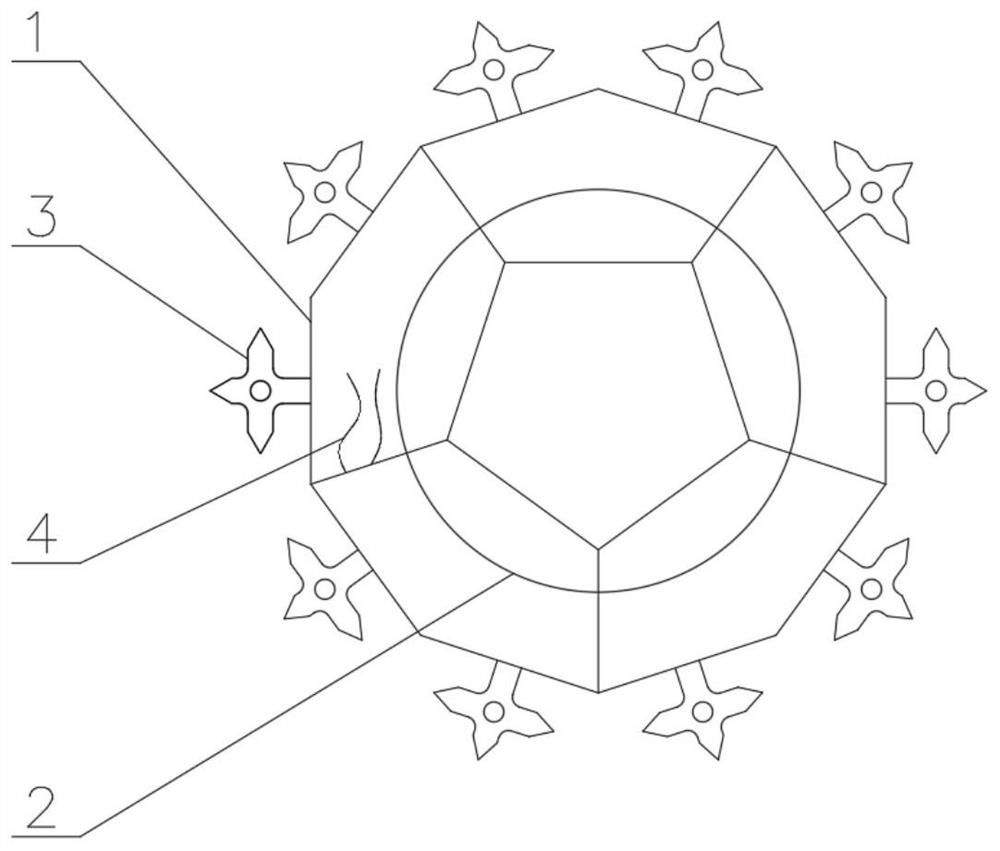

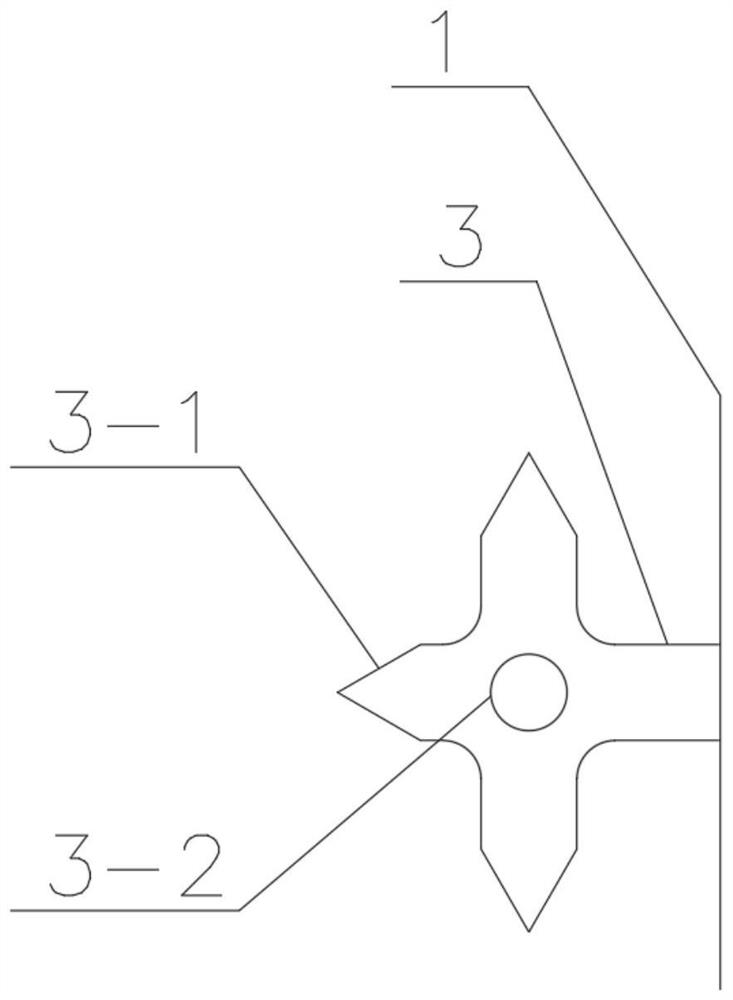

[0037] A stabilized circulating filler, comprising an outer body cage 1, an inner core ball 2, a cross-shaped wheel wing 3, wing hairs 4, wing angles 3-1 and wing holes 3-2. The specific structure and connection relationship are: the inner core ball 2 is placed in the outer body cage 1, the bottom of the cross-shaped wheel wing 3 is connected to the middle of the outer edge of the cage bar of the outer body cage 1, and the bottom of the wing hair 4 is connected to the outer edge of the outer body cage 1. The bars are irregularly connected.

[0038] The main body of the outer body cage 1 is a dodecahedron cage structure, the diameter of the outer circle is 120-160mm, the material is polypropylene, and the density is 0.89g / cm 3 -0.91g / cm 3 , The side bars of the body cage can be square bar body or round bar body structure, and the side bar thickness of the body cage is 3-8mm.

[0039] The main body of the inner core ball 2 is a sphere structure, and the sphere is a labyrinth m...

Embodiment 2

[0051] The preparation method of the stabilized and solidified circulating filler according to the present invention, its main components and mass percentages are: coconut shell activated carbon 18.5-36.5%, Alisma 2.1-3.7%, sewage treatment system press filter sludge 10.6-13.6%, Iron powder 2.7-3.9%, pine sawdust 11.6-13.2%, fir sawdust 5.7-9.3%, water hyacinth 22.6-27.4%, calamus 6.3-8.5%, glue 1.9%.

[0052] Including the following steps:

[0053] (1) Prepare the component materials for the stable and solidified circulating filler, close the compression molding machine, and add 2.1-3.7% of Alisma, 2.7-3.9% of iron powder, 22.6-27.4% of water hyacinth, and 6.3% of calamus to the compression molding machine stockyard. ~8.5%, control the temperature at 12-39 ° C, under normal pressure, start the compression molding machine to stir the above materials evenly, the stirring time is 8 minutes, and turn off the compression molding machine;

[0054] (2) Add 18.5-36.5% of coconut she...

Embodiment 3

[0059] This embodiment is an example of the application of the stabilized and solidified circulating filler described in the present invention in domestic sewage treatment, including the following steps:

[0060] A town-level domestic sewage treatment plant with an inflow volume of 500m 3 / day, design main water quality: COD Cr 3 -NCr 3 -N<5(8)mg / L, total nitrogen<15mg / L, total phosphorus<0.5mg / L, PH=6~9.

[0061] Main treatment process: sewage collection pipe network → grille → regulating tank → AO integrated sewage treatment equipment → filter cloth filter integrated machine → disinfection canal → Pasteur metering tank → standard discharge.

[0062] The sewage collection pipe network collects domestic sewage. During the collection process, the diversion of rain and sewage is controlled to prevent the rainwater from diluting the concentration of pollutants. The sewage collected through the sewage pipe network enters the grid well, and the grid well is equipped with a grid to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com