Instant peroxide high-molecular copolymer disinfection material and preparation method thereof

A polymer copolymer and peroxidation technology, applied in the fields of botanical equipment and methods, animal repellents, plant growth regulators, etc., can solve the problems of difficult dispersion, slow dissolution, inconvenient use, etc. Sterilization, strong oxidizing ability, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

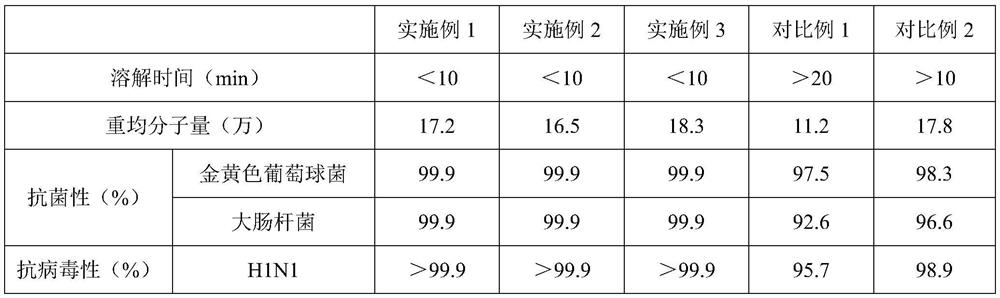

Examples

Embodiment 1

[0034] An instant peroxidized high molecular copolymer disinfection material is obtained by first reacting polyallylamine hydrochloride with gamma-aminobutyric acid modified glycidyl methacrylate, and then reacting with peroxyacrylate product of.

[0035] Wherein, the preparation method of instant peroxidized polymer copolymer disinfection material comprises the following steps:

[0036] S1. Weigh γ-aminobutyric acid and mix with acetic acid, stir and mix evenly, add glycidyl methacrylate, stir and mix at room temperature for 6 hours, and obtain γ-aminobutyric acid modified glycidyl methacrylate solution; γ - The mass ratio of aminobutyric acid to acetic acid is 1:4; the mass ratio of glycidyl methacrylate to γ-aminobutyric acid is 1:1.6;

[0037] S2. Weigh the γ-aminobutyric acid-modified glycidyl methacrylate solution, adjust the pH to 6.0-7.0 at room temperature, add polyallylamine hydrochloride solution dropwise, stir and react for 10 hours after the dropwise addition, A...

Embodiment 2

[0041] An instant peroxidized high molecular copolymer disinfection material is obtained by first reacting polyallylamine hydrochloride with gamma-aminobutyric acid modified glycidyl methacrylate, and then reacting with peroxyacrylate product of.

[0042] Wherein, the preparation method of instant peroxidized polymer copolymer disinfection material comprises the following steps:

[0043] S1. Weigh γ-aminobutyric acid and mix with acetic acid, stir and mix evenly, add glycidyl methacrylate, stir and mix at room temperature for 5 hours, and obtain γ-aminobutyric acid modified glycidyl methacrylate solution; γ -The mass ratio of aminobutyric acid to acetic acid is 1:2.5; the mass ratio of glycidyl methacrylate to γ-aminobutyric acid is 1:1.2;

[0044] S2. Weigh the γ-aminobutyric acid-modified glycidyl methacrylate solution, adjust the pH to 6.0-7.0 at room temperature, add polyallylamine hydrochloride solution dropwise, and stir for 8 hours after the addition is completed. Aft...

Embodiment 3

[0048] An instant peroxidized high molecular copolymer disinfection material is obtained by first reacting polyallylamine hydrochloride with gamma-aminobutyric acid modified glycidyl methacrylate, and then reacting with peroxyacrylate product of.

[0049] Wherein, the preparation method of instant peroxidized polymer copolymer disinfection material comprises the following steps:

[0050] S1. Weigh γ-aminobutyric acid and mix it with acetic acid, stir and mix evenly, add glycidyl methacrylate, stir and mix at room temperature for 8 hours, and obtain γ-aminobutyric acid modified glycidyl methacrylate solution; γ - The mass ratio of aminobutyric acid to acetic acid is 1:5; the mass ratio of glycidyl methacrylate to γ-aminobutyric acid is 1:1.8;

[0051] S2. Weigh the γ-aminobutyric acid-modified glycidyl methacrylate solution, adjust the pH to 6.0-7.0 at room temperature, add polyallylamine hydrochloride solution dropwise, and stir for 12 hours after the dropwise addition is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com