Synthesis of hyperbranched polylysine tertiary amine intercalation inhibitor and water-based drilling fluid

A polylysine tertiary amine and inhibitor technology, which is applied in the field of oil and gas field drilling, can solve problems such as the inability to effectively suppress well wall instability, achieve high yield, low price, and suppress hydration expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

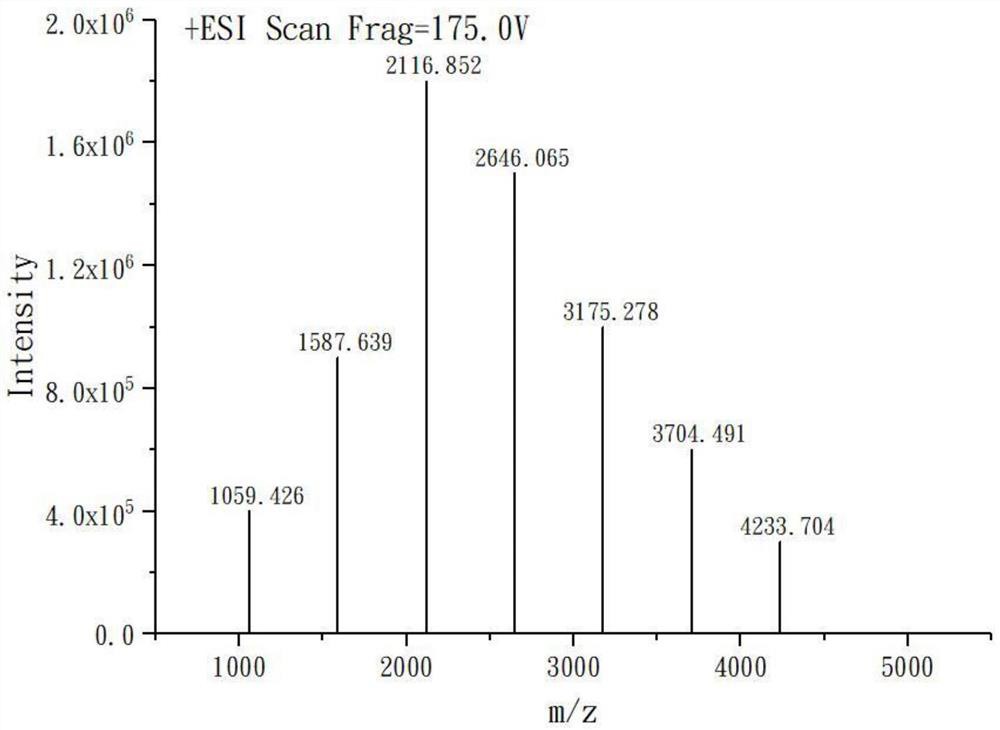

[0027] The preparation of hyperbranched polylysine tertiary amine: 0.5molN6-acetyl-L-lysine is dissolved in 100ml methanol at normal temperature, then N6-acetyl-L-lysine solution is placed in airtight container , under the conditions of nitrogen atmosphere and stirring, reflux reaction for 12h, and then the reaction product was distilled under reduced pressure to obtain N6-acetyl-L-lysine methyl ester; 0.3molN6-acetyl-L-lysine methyl ester and 0.3mol of bis(vinylsulfone methyl) ether was dissolved in 100ml of organic solvent respectively, and bis(ethylene Sulfone methyl) ether solution, after the dropwise addition is completed, heat up to 65°C for reflux reaction for 8h and then distill under reduced pressure to obtain hyperbranched polylysine; take 0.2mol hyperbranched polylysine and dissolve it in 100ml organic solvent, 0.2mol1- Methyl-2-propene-1-aminomethanol was dissolved in 50ml of organic solvent, and was added dropwise to hyperbranched polylysine under nitrogen atmosph...

Embodiment 2

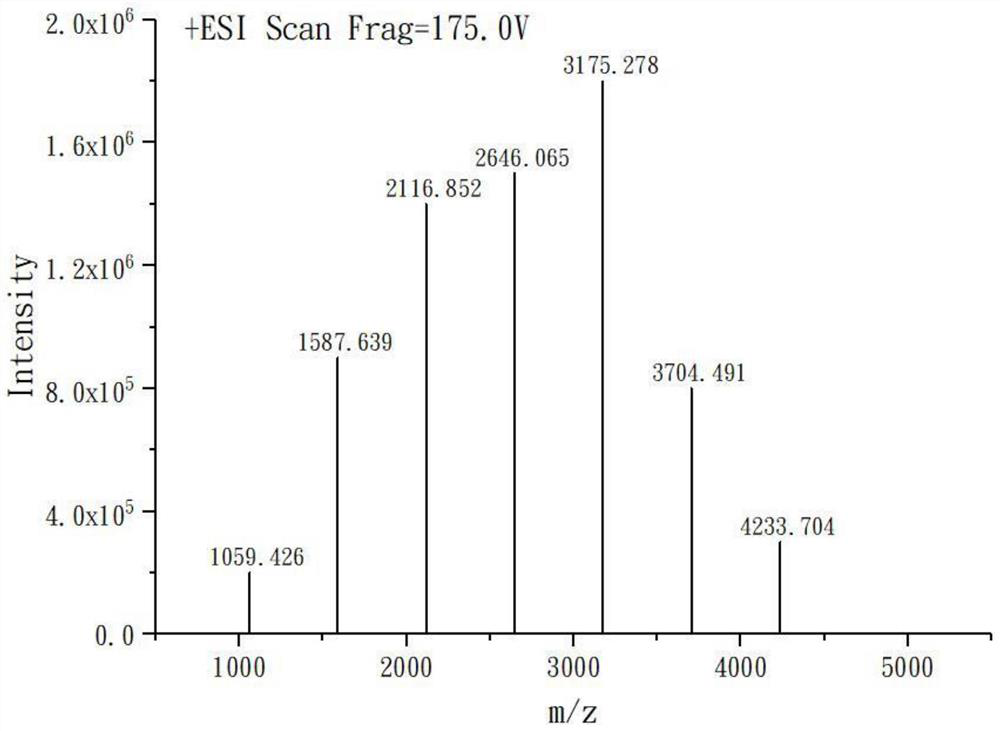

[0029] The preparation of hyperbranched polylysine tertiary amine: 0.5molN6-acetyl-L-lysine is dissolved in 100ml methanol solution at normal temperature, then N6-acetyl-L-lysine solution is placed in airtight container , under the conditions of nitrogen atmosphere and stirring, reflux reaction for 15h, and then the reaction product was distilled under reduced pressure to obtain N6-acetyl-L-lysine methyl ester; 0.3molN6-acetyl-L-lysine methyl ester and 0.3mol 2-methylene-succinic acid 1,4-divinyl ester were dissolved in 100ml organic solvent respectively, and N6-acetyl-L-lysine methyl ester 2-methylene-succinic acid 1,4-divinyl ester solution was added dropwise in the solution, after the dropwise addition was completed, the temperature was raised to 70° C. for reflux reaction for 10 h, and then the hyperbranched polylysine was obtained by distillation under reduced pressure; 0.2mol hyperbranched polylysine was dissolved in 100ml organic solvent, 0.2mol 1-methyl-2-propene-1-ami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com