Biogas fermentation liquor recycling method

A biogas fermentation liquid and biogas fermentation technology, applied in the field of biogas fermentation liquid reuse, can solve the problems of adding chemicals, high energy consumption and labor costs, blockage of pipelines, deposition of struvite, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Follow the normal fermentation process. After the biogas fermentation is completed, add 50ppm polyacrylamide to the fermentation supernatant for flocculation, and then filter through a plate and frame filter, and reuse 1 / 3 of the filtered fermentation liquid.

Embodiment 2

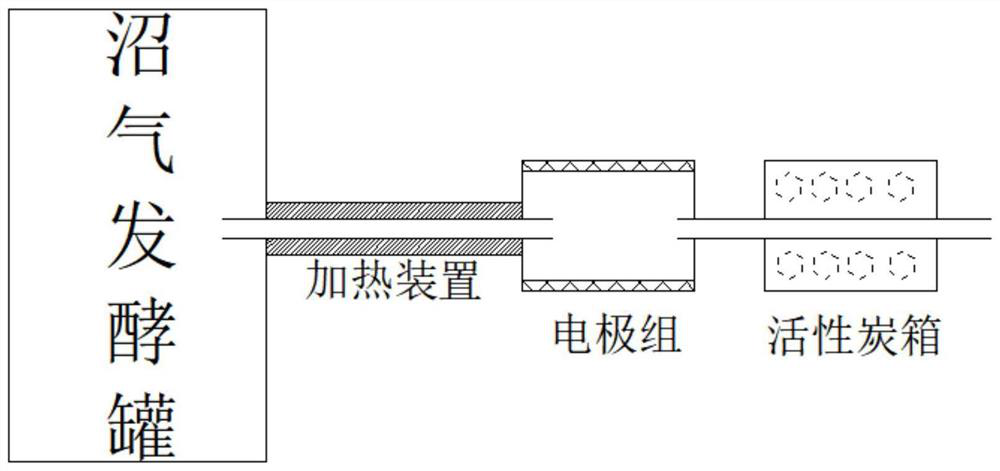

[0012] The supernatant is extracted from the upper 1 / 3 of the biogas fermentation tank, and the supernatant passes through a pipeline with a heating device to heat the supernatant to 30 degrees, and then passes through a box with positive and negative electrode groups, and the voltage It is 220V, the current is 60A, and finally passes through the box filled with activated carbon box. The treated fermentation broth is all returned to the biogas fermentation tank to continue fermentation. figure 1 It is a schematic diagram of the device structure for realizing this embodiment.

Embodiment 3

[0014] The supernatant is extracted from the upper 1 / 2 of the biogas fermentation tank, and the supernatant passes through a pipeline with a heating device to heat the supernatant to 40 degrees, and then passes through a box with positive and negative electrode groups, and the voltage It is 220V, the current is 120A, and finally passes through the box filled with activated carbon box. The treated fermentation broth is all returned to the biogas fermentation tank to continue fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com