Nano imbibition agent as well as preparation method and application thereof

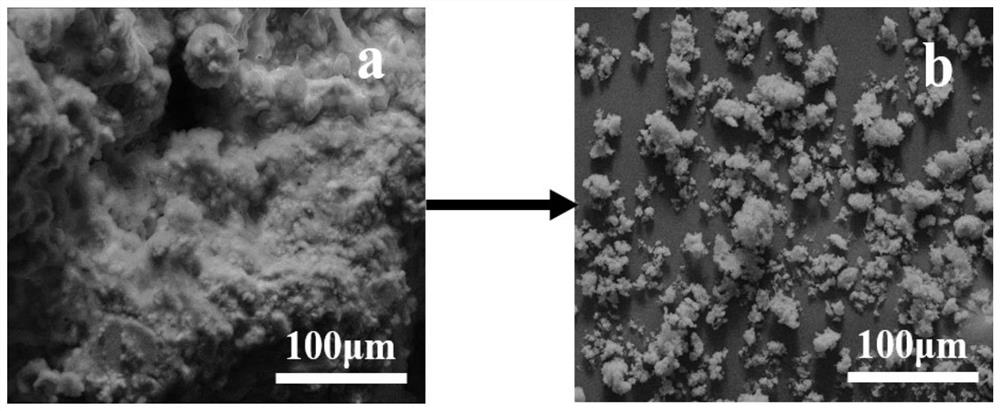

An imbibition agent and nanotechnology, applied in the field of nano imbibition agent preparation, can solve the problems of weak dialysis ability, poor temperature resistance, low water solubility, etc., and achieve the effects of preventing secondary aggregation, good stability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

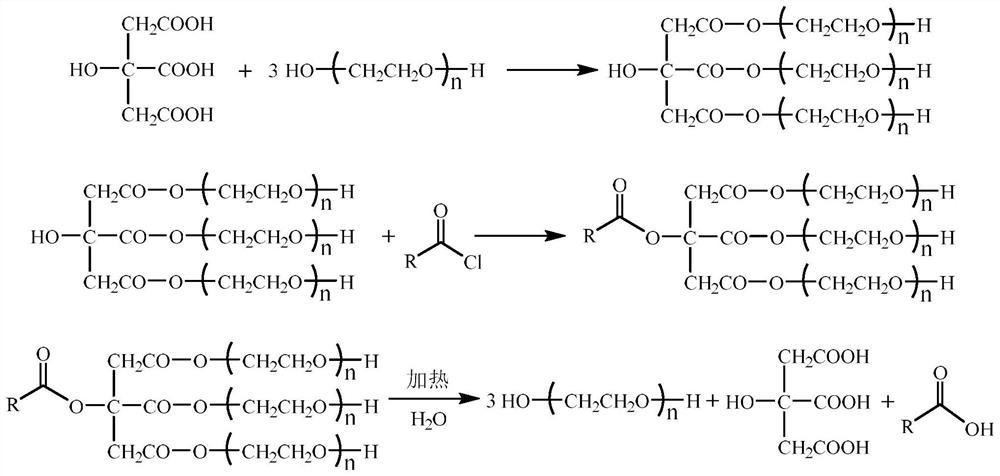

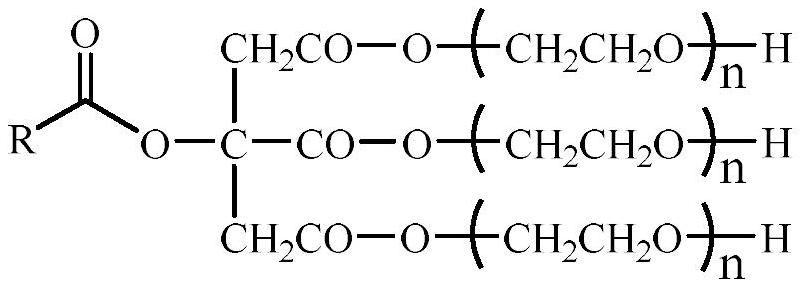

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of nano absorbent, comprising the following steps:

[0041] Mix 9.6g of citric acid and 68.7g of polyoxyethylene (n=10) in 467.5g of solvent dimethylformamide, raise the temperature to 95°C, and carry out the first step of reaction, and react for 2 hours to obtain a mixed solution after reaction . Control the temperature of the mixed solution after the reaction at 30°C, then add 15.2g of octadecyl chloride to the mixed solution after the reaction to carry out the second step reaction, react for 4h, obtain the reaction solution after the reaction, concentrate the reaction solution, and use toluene The product was purified and separated by column chromatography, and vacuum-dried to constant weight to obtain a nano-absorbent.

Embodiment 2

[0043] A preparation method of nano absorbent, comprising the following steps:

[0044]Mix 9.6g of citric acid and 139.2g of polyoxyethylene (n=20) in 488.0g of solvent dimethylformamide, raise the temperature to 95°C, and carry out the first step of reaction, and react for 2 hours to obtain a mixed solution after reaction . Control the temperature of the mixed solution after the reaction at 30°C, then add 13.8g of octadecyl chloride to the mixed solution after the reaction to carry out the second step reaction, react for 4h, obtain the reaction solution after the reaction, concentrate the reaction solution, and use toluene The product was purified and separated by column chromatography, and vacuum-dried to constant weight to obtain a nano-absorbent.

Embodiment 3

[0046] A preparation method of nano absorbent, comprising the following steps:

[0047] Mix 10.6g of citric acid and 75.6g of polyoxyethylene (n=10) in 411.6g of solvent dimethylformamide, raise the temperature to 90°C, and perform the first step of reaction, and react for 2 hours to obtain a mixed solution after reaction . Control the temperature of the mixed solution after the reaction at 25°C, then add 16.7g of octadecyl chloride to the mixed solution after the reaction to carry out the second step reaction, react for 3h, obtain the reaction solution after the reaction is completed, concentrate the reaction solution, and use toluene The product was purified and separated by column chromatography, and vacuum-dried to constant weight to obtain a nano-absorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com