Preparation method of organic-inorganic hybrid perovskite thin film

A technology of perovskite and perovskite precursors, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as increasing the risk of experimental failure, and achieve simple operation, low cost, and process. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing an organic-inorganic hybrid perovskite film, the method comprising the following steps:

[0035] First, the PbI 2 The powder and the PEAI powder were added to the solvent in turn, and stirred for 10-20 minutes to fully dissolve it to obtain (PEA) 2 PB 4 Perovskite precursor solution; the solvent is a polar solvent, including N,N-dimethylformamide (DMF), γ-butyrolactone or dimethyl sulfoxide (DMSO). (PEA) 2 PB 4 PbI in perovskite precursor solution 2 and PEAI concentrations were 0.8-1.2mol / L and 1.6-2.4mol / L. PB 2 The ratio of the amount of substance to PEAI is preferably 1:2.

[0036] Then, the prepared (PEA) 2 PB 4 The perovskite precursor solution is dripped on the cleaned substrate material, and the substrate material includes ordinary glass, ITO glass, FTO glass or sapphire. (PEA) was spin-coated 2 PB 4 The perovskite precursor solution is evenly coated, and the solvent is evaporated by natural drying to obtain (PEA) 2 PB 4Organi...

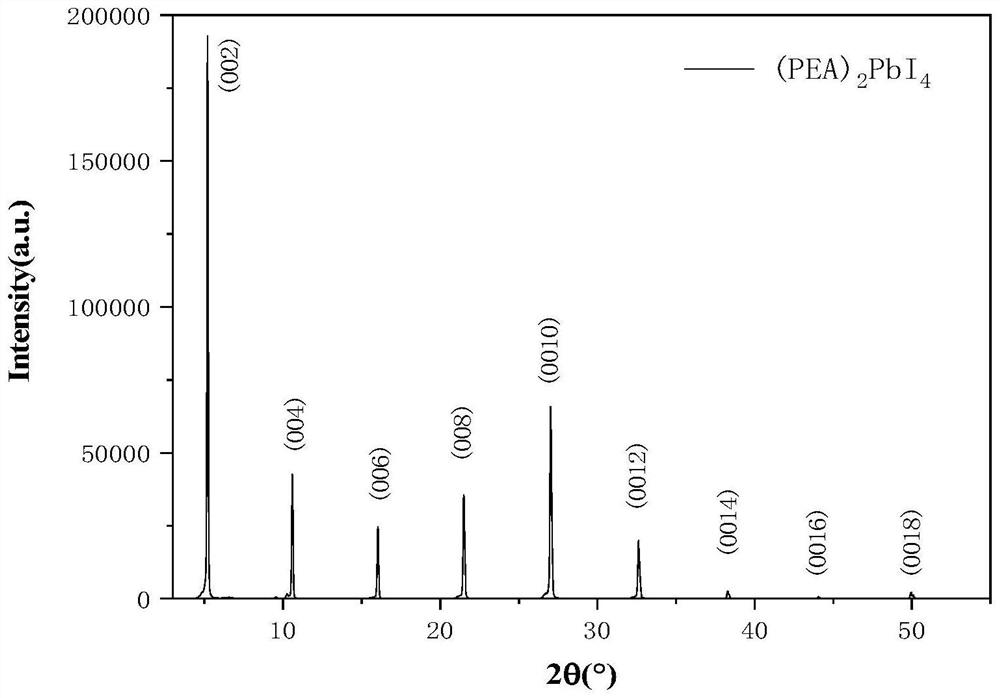

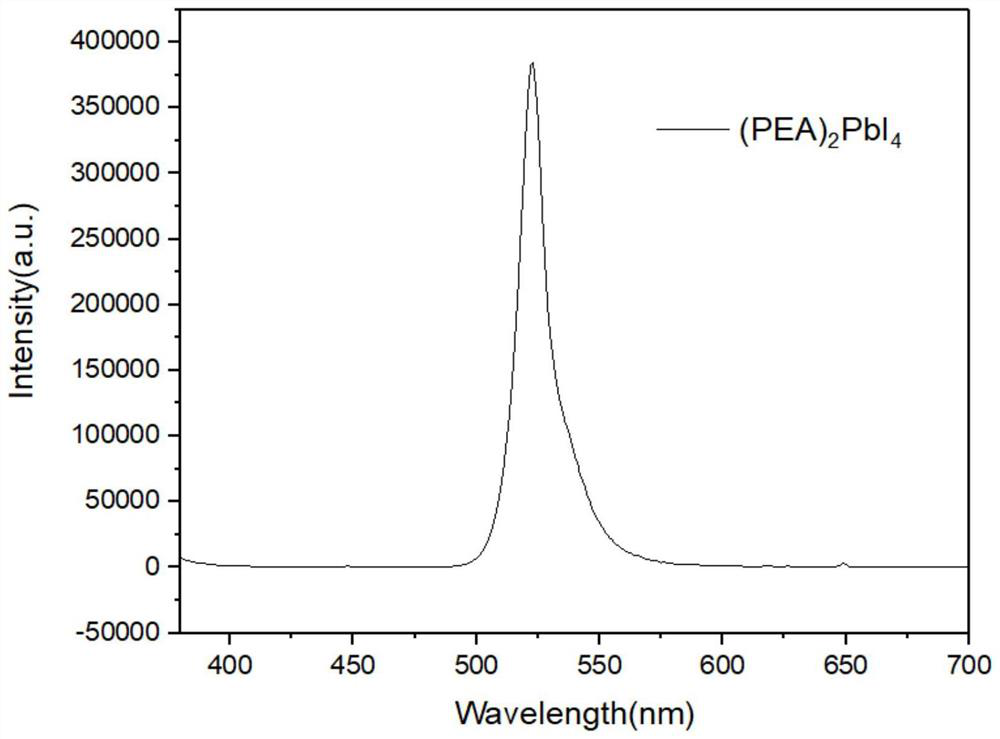

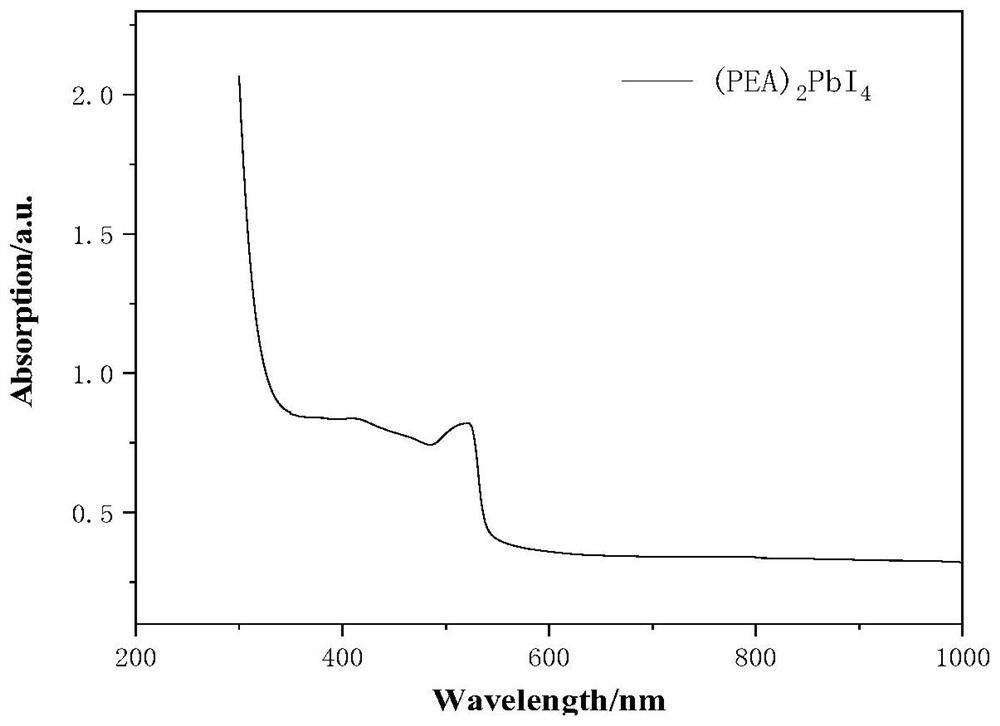

Embodiment 1

[0038] A preparation method of an organic-inorganic hybrid perovskite film, specifically comprising the steps of:

[0039] (1) First according to PbI 2 : The molar ratio of PEAI=1:2 takes by weighing 0.6915g and 0.747g respectively, joins in the gamma-butyrolactone of 1mL successively to form a solution, stirs 10-20min, utilizes solution method to make PbI 2 React with PEAI to dissolve completely, forming a yellow transparent, slightly viscous precursor solution;

[0040] (2) Use a pipette gun to extract 1 μL of the perovskite precursor solution prepared in step (1), and then drop it on a common glass substrate that is cleaned with ethanol and γ-butyrolactone in sequence. Set the initial spin-coating speed to 500rpm. After 90 seconds of spin-coating, increase the spin-coating speed to 800-1000rpm, and continue to spin-coat for 120 seconds. During this process, it is gradually seen that yellow crystals start to precipitate on the film substrate, and then increase again. Spin ...

Embodiment 2

[0048] A preparation method of an organic-inorganic hybrid perovskite film, specifically comprising the steps of:

[0049] (1) First according to PbI 2 : The ratio of PEAI=1:2 takes by weighing 0.461g and 0.498g respectively, joins in the gamma-butyrolactone solvent of 1mL successively, stirs 10-20min, makes PbI 2 Dissolve PEAI and γ-butyrolactone in γ-butyrolactone completely, and generate a yellow and transparent precursor solution with a concentration of 1mol / L after fully reacting;

[0050] (2) Add a little of the perovskite precursor solution prepared in step (1) dropwise on the common glass substrate cleaned with ethanol and γ-butyrolactone in sequence. The initial spin-coating speed is 500rpm. After 90 seconds of spin-coating, increase the spin-coating speed to 800-1000rpm, continue to spin-coat for 120 seconds, then gradually increase the spin-coating speed to 2000rpm, and continue to spin-coat for 60 seconds. After the end, reduce the spin-coating speed until the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com