Impregnation liquid for improving flavor of crisp peach chips and preparation method of flavored crisp peach chips

A technology for peach crisps and dipping liquid, which is applied in the field of preparation of dipping liquid and flavored peach crisps, can solve the problem of low level of flavor improvement of peach crisps, achieve wide practicability and reproducibility, and the method is simple, easy and rich Kind of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050]The present invention also provides a preparation method for flavored peach crisps, comprising the following steps:

[0051] Step 1. Take the peach slices and immerse them in the soaking solution for osmotic dehydration treatment. After the osmotic dehydration treatment, wash the sugar solution on the surface of the peach slices after the osmotic dehydration treatment, and dry the surface moisture to obtain osmotic dehydration peach slices. The peach slices The mass ratio to the soaking liquid is 1:5-1:15, wherein, in parts by weight, the soaking liquid contains the following components: 250-400 parts of Maofeng tea, 3-8 parts of honey, erythorbic acid 0.5-1 part of sodium, 25-40 parts of sucrose, 10-35 parts of isomaltooligosaccharide, 10-30 parts of maltitol and 5-30 parts of sorbitol;

[0052] Step 2, drying the osmotic dehydrated peach slices to obtain flavored peach crisp slices.

[0053] In the above scheme, as preferably, the following steps are also included bef...

Embodiment 1

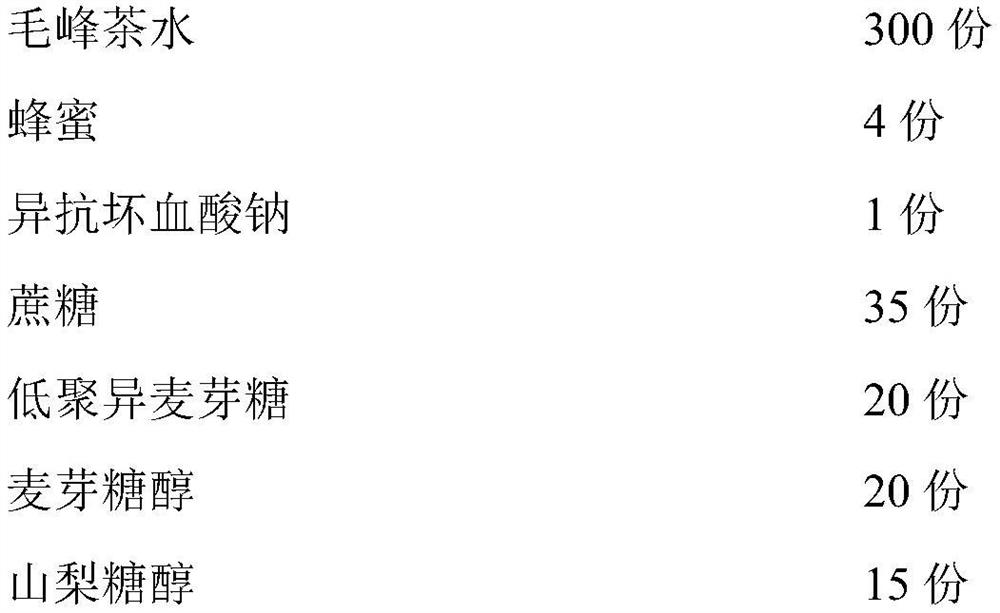

[0076] A dipping solution for improving the flavor of peach crisps, comprising the following raw materials in parts by mass:

[0077]

[0078] (1) Preparation of dipping solution for improving peach crisp flavor

[0079] Brew Maofeng tea leaves with 85°C hot water, the brewing ratio of tea water is 1:30 (w / v), and the brewing time is 5 minutes. After brewing, filter the tea leaves with a tea filter to obtain pure tea water, and cool the tea water naturally After room temperature, add sucrose, isomaltooligosaccharide, maltitol, and sorbitol into the tea according to the above-mentioned parts by mass, fully dissolve and mix well, add honey and sodium erythorbate, and obtain the described flavor-improving peach crisp Dipping solution.

[0080] (2) The preparation method of flavor peach crisp chips

[0081] (1) Select fresh, pest-free late No. 24 white peaches, wash the fresh peaches, peel them, and remove the pits. Use a slicer to cut the peaches into 8mm-thick fan-shaped sl...

Embodiment 2

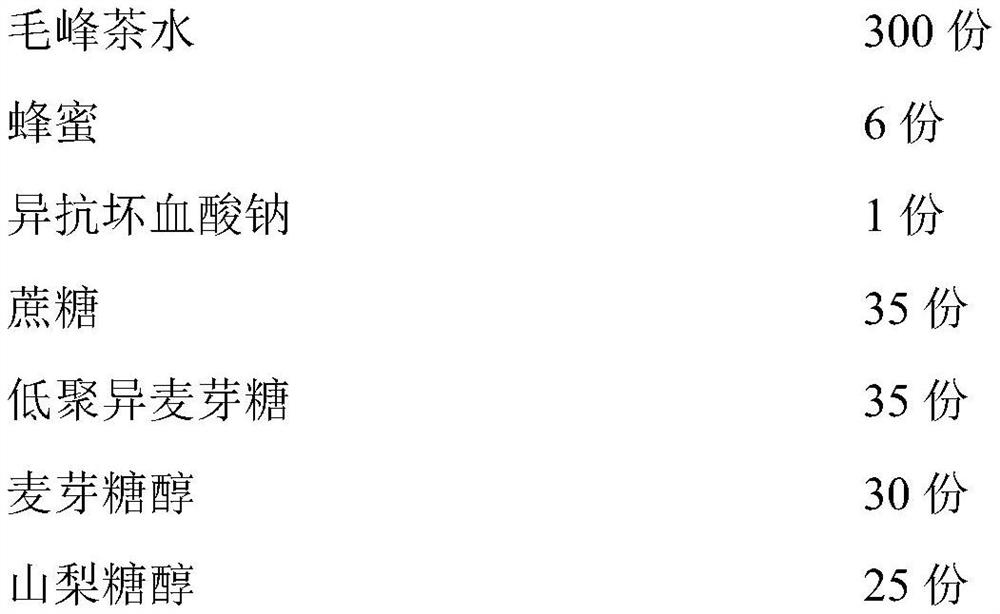

[0091] A dipping solution for improving the flavor of peach crisps, comprising the following raw materials in parts by mass:

[0092]

[0093] (1) Preparation of dipping solution for improving peach crisp flavor

[0094] Brew Maofeng tea leaves with hot water at 80°C, the brewing ratio of tea water is 1:25 (w / v), and the brewing time is 5 minutes. After room temperature, add sucrose, isomaltooligosaccharide, maltitol, and sorbitol into the tea according to the above-mentioned parts by mass, fully dissolve and mix well, add honey and sodium erythorbate, and obtain the described flavor-improving peach crisp Dipping solution.

[0095] (2) The preparation method of flavor peach crisp chips

[0096] (1) Select fresh, pest-free late No. 24 white peaches, wash the fresh peaches, peel them, and remove the pits. Use a slicer to cut the peaches into 8mm-thick fan-shaped slices, and then seal them in bags and freeze them in a -40°C freezer. Save for later use;

[0097] (2) Transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com