Comprehensive method for removing non-condensable gas dissolved in refrigerant

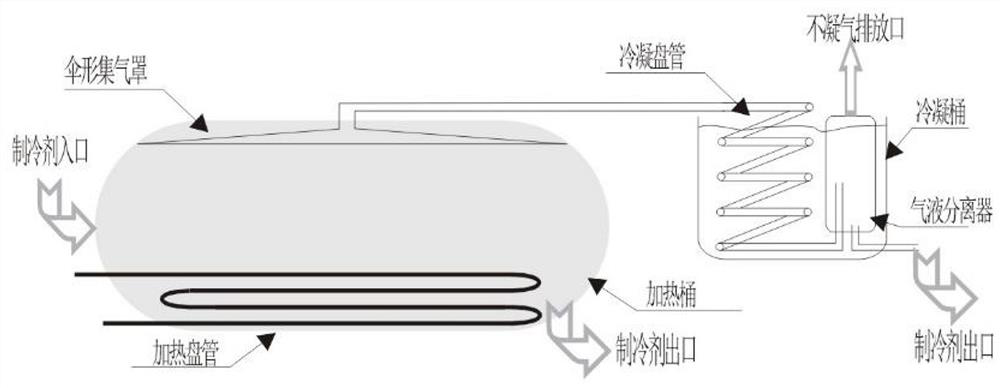

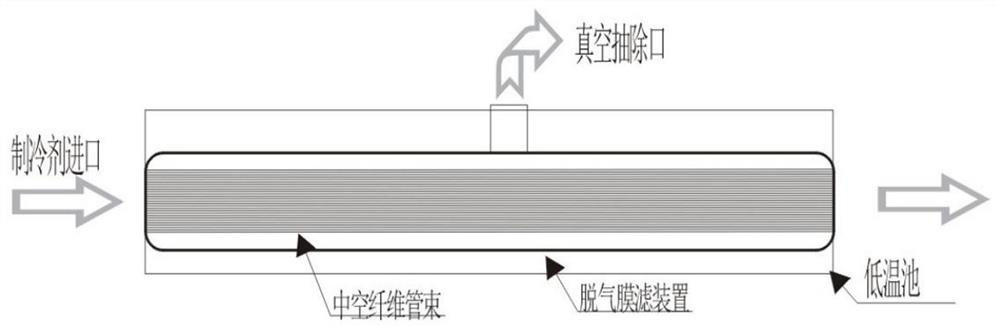

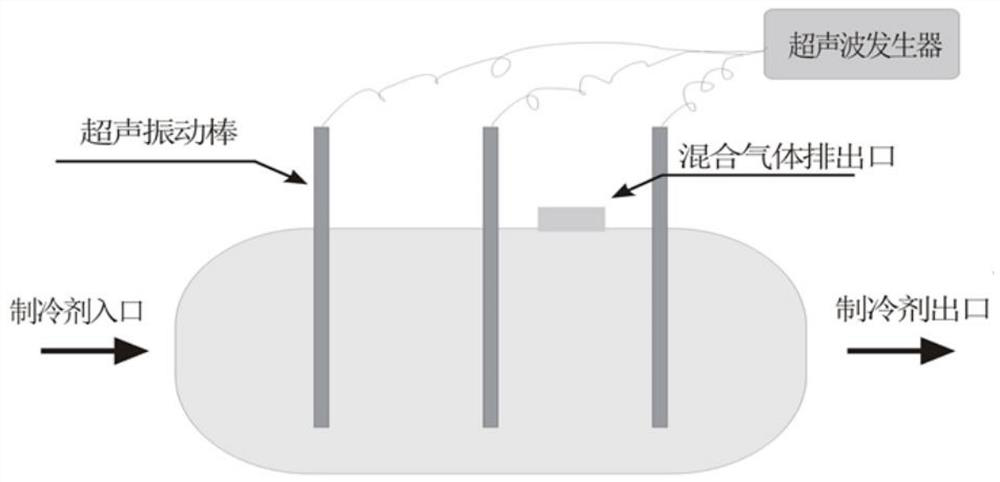

A refrigerant, comprehensive method technology, applied in the direction of liquid degassing, liquid degassing by vibration, liquid degassing by filtering, etc., can solve the problems of damage to the air conditioning system, increase of condensation pressure, increase of energy consumption, etc., to improve utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0078] Taking R134a (800 liter volume steel cylinder, 1000 kg) produced by Zhejiang Quzhou Juhua Group as the target test object, first use the sampling bottle to take the liquid phase refrigerant, and then use the GC126N gas chromatograph of Shanghai Yidian Analytical Instrument Co., Ltd. GB / T33063-2016 "Fluoroolefin Noncondensable Gases for Refrigerants

[0079] (NCG) General Method for Determination of Thermal Conductivity (TCD) detection;

[0080] The initial values are as follows: (only the main non-condensable gases N2 and O2 are listed)

[0081] Detection index item N2 O2 Detection value % (V / V) 1.1702 0.4211

[0082] Then use the WKT-A6 automatic Karl Fischer trace moisture analyzer produced by Taizhou Ketuo Instrument Equipment Co., Ltd. according to GB / T7376-2008 "Determination of trace moisture in industrial fluorinated alkanes Karl Fischer method" Water content detection;

[0083] The initial values are as follows:

[0084] De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com