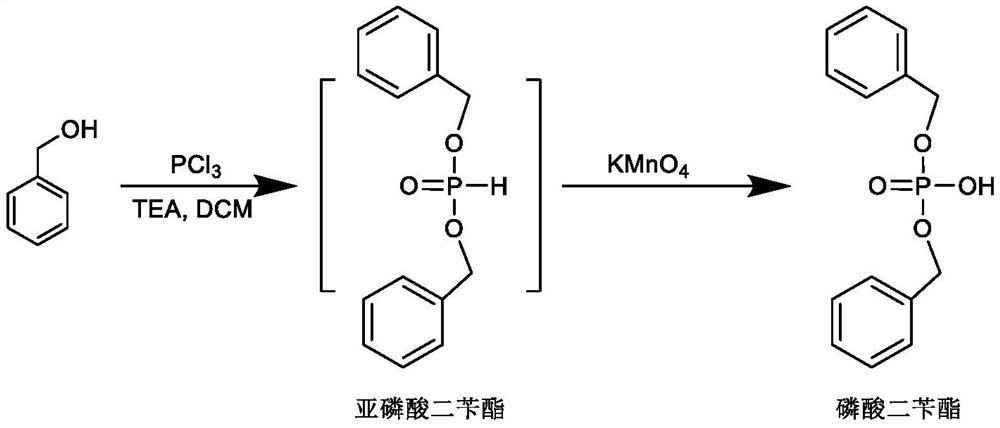

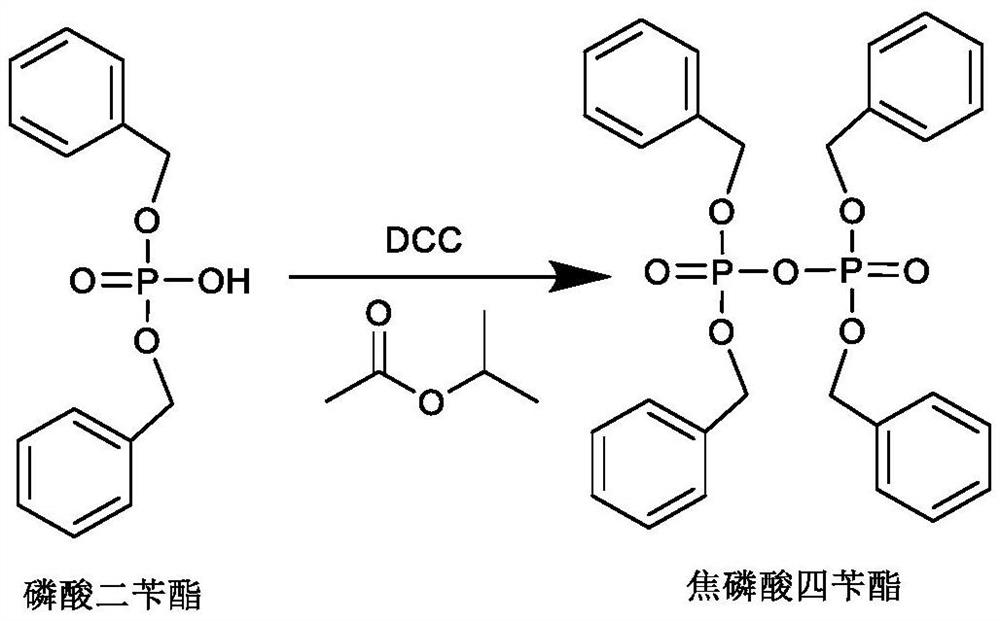

Preparation method of dibenzyl phosphate and tetrabenzyl pyrophosphate

A technology of tetrabenzyl pyrophosphate and dibenzyl phosphate is applied in the field of preparation of pharmaceutical intermediates and achieves the effects of low cost, mild reaction conditions and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

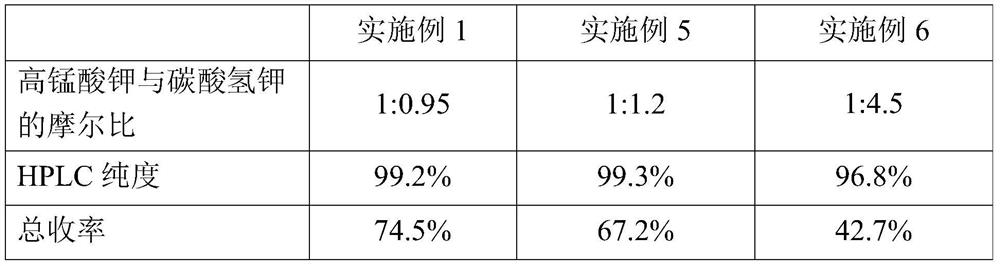

Examples

Embodiment 1

[0064] 1. Preparation of dibenzyl phosphate

[0065]

[0066] Include the following steps:

[0067] ①. Add 41kg (about 379mol) of benzyl alcohol, 41kg (about 405mol) of triethylamine and 27.0kg (about 197mol) of phosphorus trichloride to 300kg of dichloromethane. After the addition is complete, keep the temperature at 20-25°C for 30 minutes. After TLC (thin layer chromatography) detects that reaction is substantially complete (remaining amount of benzyl alcohol≤2wt%), obtain the reaction solution containing dibenzyl phosphite, cool to-3~3 ℃, add 150kg purified water to quench the reaction, stir 10min, stand still, separate the liquids, take the organic phase, extract the upper aqueous phase with dichloromethane (30kg×3) for 3 times, combine the organic phases, and then distill under reduced pressure (vacuum degree≤-0.09MPa, temperature 30~35°C) To substantially not going out distillate, obtain dibenzyl phosphite;

[0068] Further purification:

[0069] The above-mentione...

Embodiment 2

[0083]The same content as in Example 1 will not be repeated, but the difference is that in the step 1 of preparing dibenzyl phosphate, the consumption of triethylamine is adjusted to 38.5kg (about 380mol), that is: the mole of benzyl alcohol and triethylamine The ratio was 1:1, and dibenzyl phosphate was prepared as a white powdery solid with a HPLC purity of 99.1% and a total yield of 68.8% (based on benzyl alcohol).

Embodiment 3

[0085] The same content as in Example 1 will not be repeated, but the difference is that in the step 1 of preparing dibenzyl phosphate, the amount of phosphorus trichloride is adjusted to 26.1kg (about 190mol), that is: benzyl alcohol and phosphorus trichloride The molar ratio of dibenzyl phosphate was 1:0.5 to prepare dibenzyl phosphate, a white powdery solid, with a HPLC purity of 99.4% and a total yield of 72.5% (calculated as benzyl alcohol).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com