Bismuth/bismuth ferrite visible-light-driven photocatalyst material as well as preparation method and application thereof

A technology of bismuth ferrite and visible light, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of cost increase, affecting the service life of photocatalysts, structural instability, etc., and achieve low price , The preparation method is flexible and controllable, and the effect of strong structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Dissolve 0.004mol of bismuth nitrate pentahydrate and 0.002mol of ferric nitrate nonahydrate in 20mL of ethylene glycol methyl ether, mix well, add 0.006mol of tartaric acid until completely dissolved, add 25mL of concentrated ammonia water dropwise until the viscosity of the system rises, then dry at 120°C, Grinding, the ground sample was heated from 80°C to 600°C with a heating rate of 5°C / min, and was reduced with 0.05mol sodium borohydride at 500°C for 60 minutes, and then washed and centrifuged with absolute ethanol and deionized water several times to obtain Bismuth / bismuth ferrite photocatalytic composites.

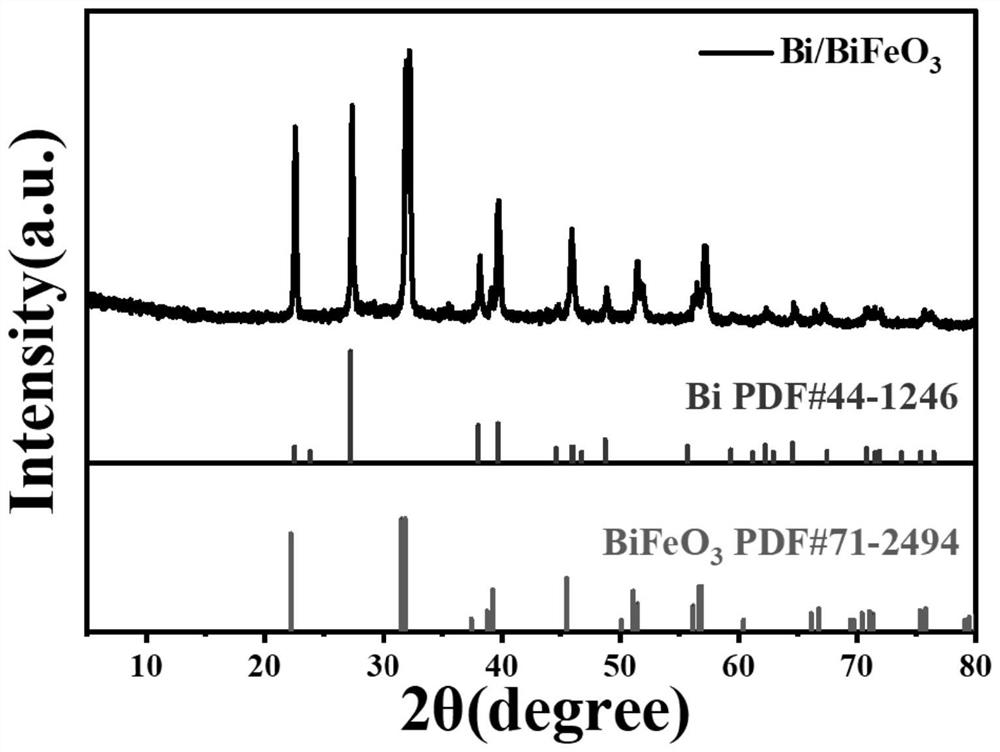

[0041] The XRD spectrum of the bismuth / bismuth ferrite photocatalytic composite material prepared in this embodiment is as follows figure 1 , indicating that bismuth metal was grown in situ during the synthesis of bismuth ferrite.

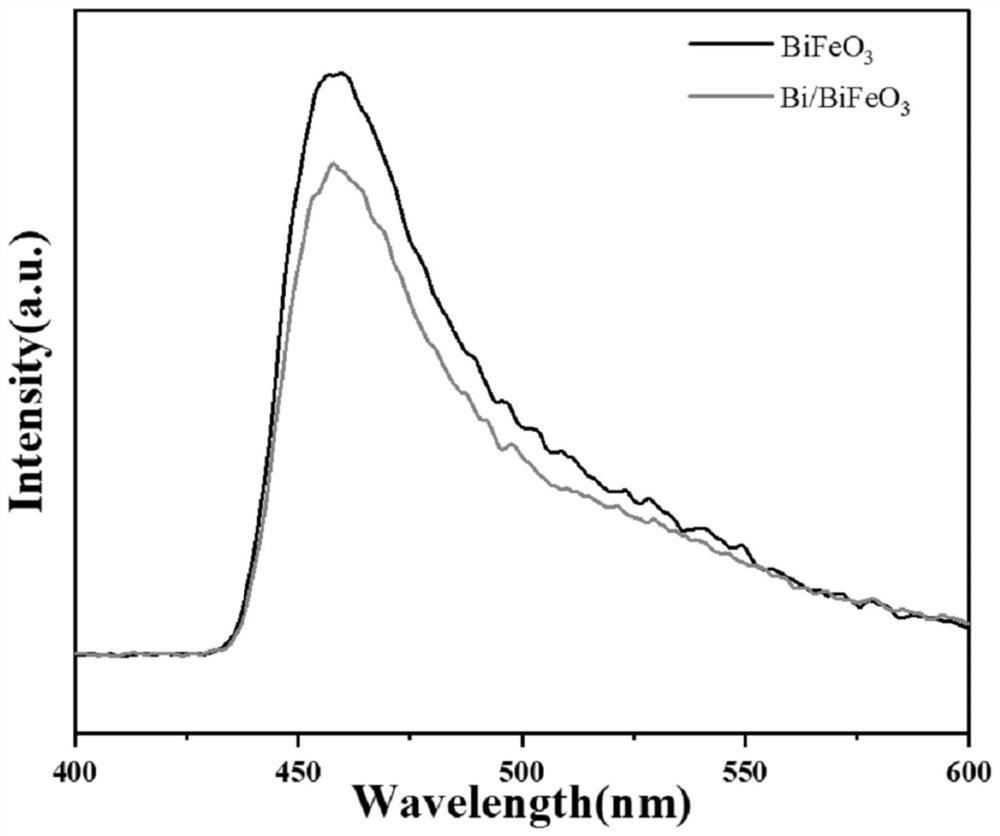

[0042] figure 2 It can be seen that the bismuth / bismuth ferrite photocatalytic material system has a lower photoluminescence...

Embodiment 2

[0046] Dissolve 0.004mol of bismuth nitrate pentahydrate and 0.002mol of ferric nitrate nonahydrate in 20mL of isopropanol and mix well, then add 0.006mol of citric acid until completely dissolved, add 10mL of concentrated ammonia water dropwise until the viscosity of the system rises, then dry and grind at 120°C , the ground sample was heated from 100°C to 600°C with a heating rate of 5°C / min, and was reduced with 0.05mol sodium borohydride at 600°C for 30min, then washed and centrifuged with absolute ethanol and deionized water several times to obtain bismuth / Bismuth ferrite photocatalytic composites.

Embodiment 3

[0048] Dissolve 0.004mol of bismuth nitrate pentahydrate and 0.002mol of ferric nitrate nonahydrate in 20mL of ethylene glycol, mix well, add 0.006mol of gluconic acid until completely dissolved, add 20mL of concentrated ammonia water dropwise until the viscosity of the system rises, then dry and grind at 120°C , the ground sample was heated from 100°C to 600°C with a heating rate of 5°C / min, and was reduced with 0.05mol sodium borohydride at 400°C for 60min, then washed and centrifuged with absolute ethanol and deionized water several times to obtain bismuth / Bismuth ferrite photocatalytic composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com