Novel plasticizer-free soft PVC (polyvinyl chloride) and preparation method thereof

A plasticizer and soft technology, which is applied to the new type of soft PVC without plasticizer and its preparation field, can solve the problems of changes in physical and chemical properties, affecting product performance and service life, and plasticizer overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

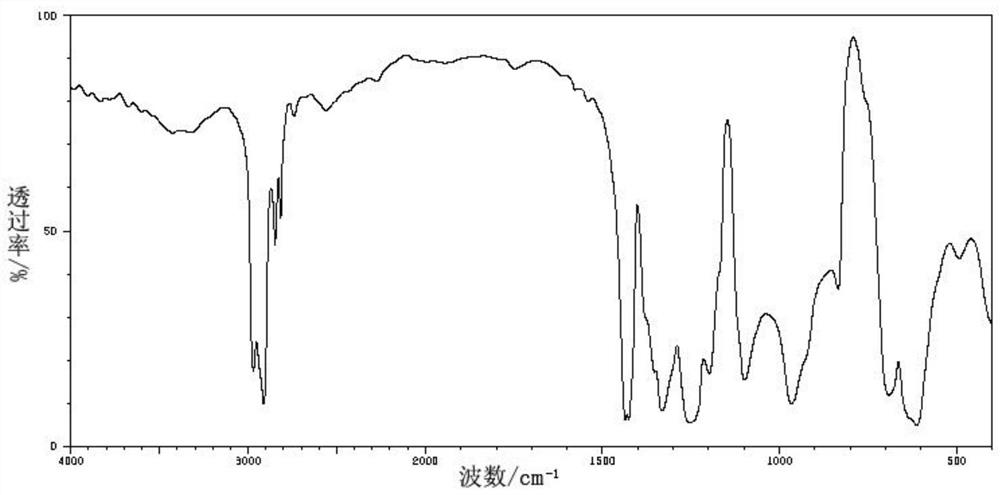

Embodiment 1

[0035] A novel soft PVC without plasticizer is prepared by the following method:

[0036] S1. Prepare the vinyl chloride monomer Amol, prepare the first comonomer B mol; the structural formula of the first comonomer is:

[0037] S2. Add the first copolymer monomer into the deionized water, add the dispersant and fully stir to disperse, then add the initiator, adjust the system temperature to 40°C±2°C, and keep it for 4min to obtain the copolymer suspension.

[0038] S3. After replacing the air in the reactor with an inert gas, inject vinyl chloride gas into the copolymer suspension, adjust the temperature of the system to 60° C., and maintain it for 2.5 hours to obtain a reaction product.

[0039] S4. The reaction product is subjected to solid-liquid separation, washing and drying to obtain the soft PVC.

[0040] Wherein: the number of moles B of the first comonomer satisfies B=A / K 1 , K 1 Take 14. R 1 for N atoms, R 2 and R 3 same; the R 2 , R 3 Both are C 12 of a...

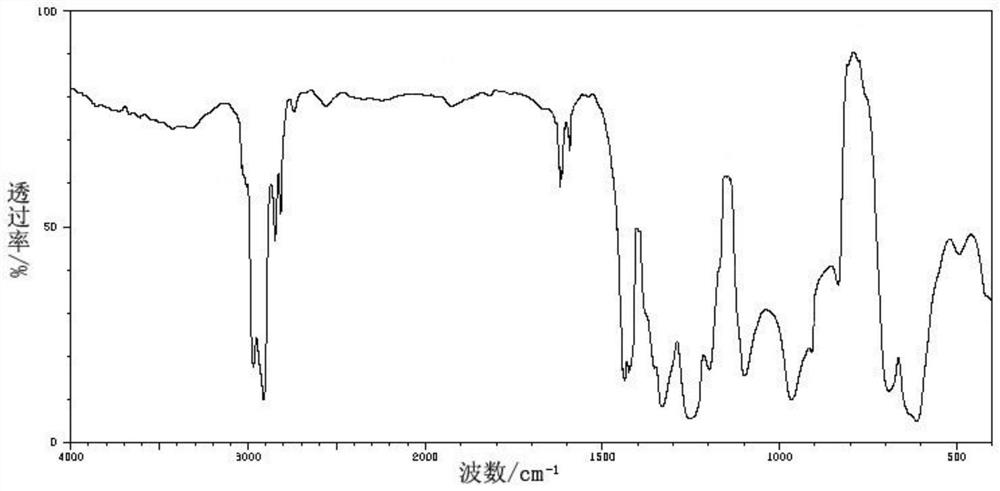

Embodiment 2

[0044] A novel soft PVC without plasticizer is prepared by the following method:

[0045] S1. Prepare the vinyl chloride monomer Amol, prepare the first comonomer B mol; the structural formula of the first comonomer is:

[0046] S2. Add the first copolymer monomer into the deionized water, add the dispersant and fully stir to disperse, then add the initiator, adjust the system temperature to 40°C±2°C, and keep it for 5min to obtain the copolymer suspension.

[0047] S3. After replacing the air in the reactor with an inert gas, inject vinyl chloride gas into the copolymer suspension, adjust the temperature of the system to 70° C., and maintain it for 2 hours to obtain a reaction product.

[0048] S4. The reaction product is subjected to solid-liquid separation, washing and drying to obtain the soft PVC.

[0049] Wherein: the number of moles B of the first comonomer satisfies B=A / K 1 , K 1 Take 15. R 1 is the S atom, R 2 and R 3 different; the R 2 for C 12 alkanes, R 3...

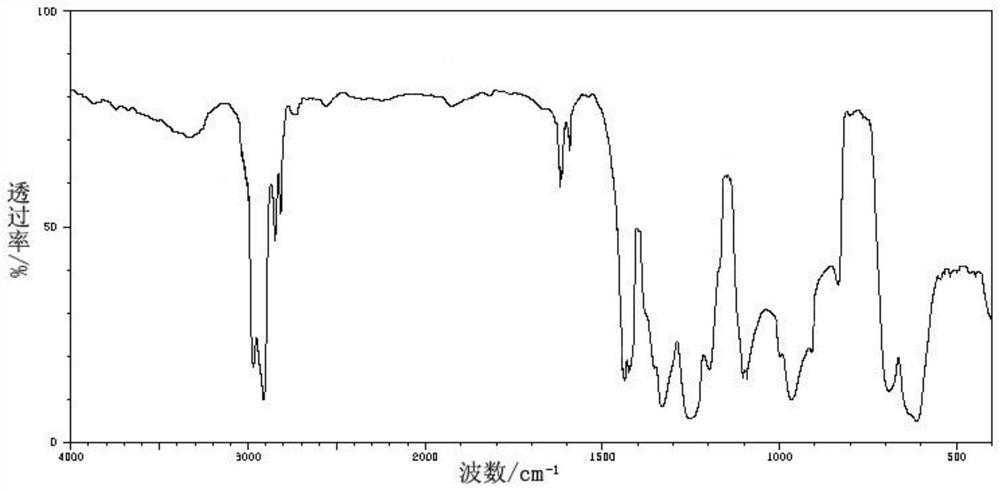

Embodiment 3

[0053] A novel soft PVC without plasticizer is prepared by the following method:

[0054] S1. Prepare the vinyl chloride monomer Amol, prepare the first comonomer B mol; the structural formula of the first comonomer is:

[0055] S2. Add the first copolymer monomer into the deionized water, add the dispersant and fully stir to disperse, then add the initiator, adjust the temperature of the system to 40°C±2°C, and keep it for 3min to obtain a copolymer suspension.

[0056] S3. After replacing the air in the reactor with an inert gas, inject vinyl chloride gas into the copolymer suspension, adjust the temperature of the system to 50° C., and maintain it for 3 hours to obtain a reaction product.

[0057] S4. The reaction product is subjected to solid-liquid separation, washing and drying to obtain the soft PVC.

[0058] Wherein: the number of moles B of the first comonomer satisfies B=A / K 1 , K 1 Take 13. R 1 is the P atom, R 2 and R 3 same; the R 2 , R 3 Both are C 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com