Method for infiltrating and connecting CuW and CuCr materials through high-entropy alloy

A high-entropy alloy and infiltration technology, applied in the field of heterogeneous material preparation, can solve problems such as low interface bonding strength, and achieve the effects of low cost, simple process and good connection adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

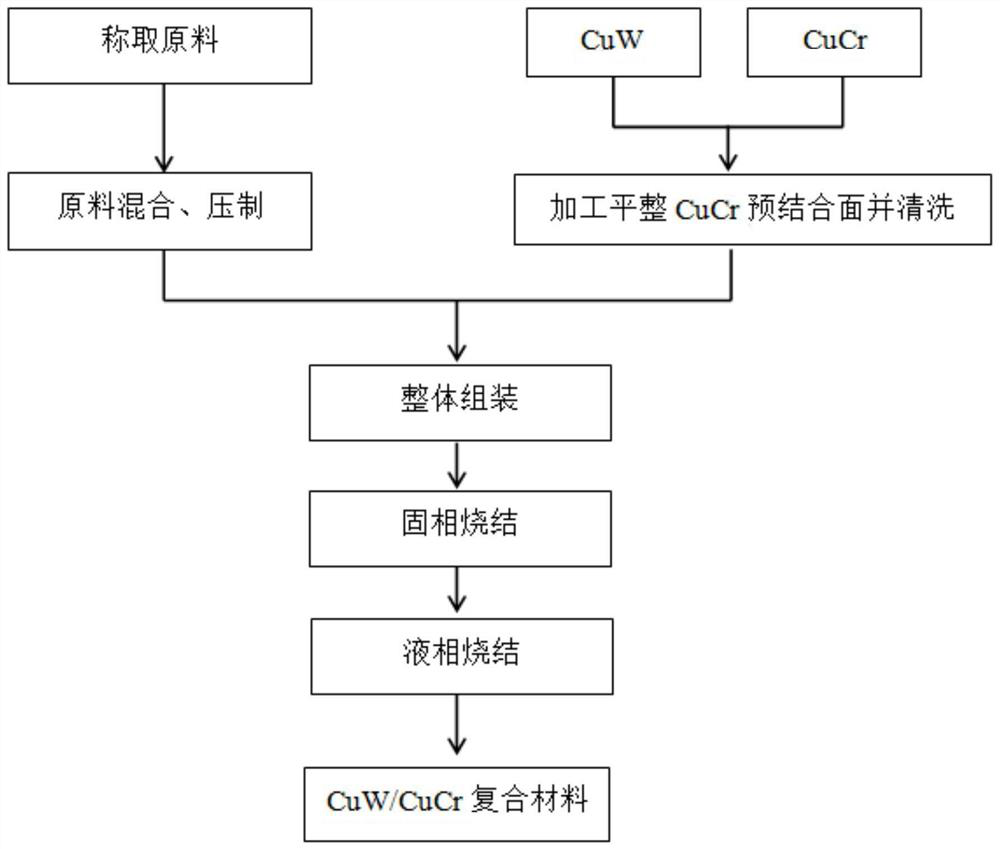

Method used

Image

Examples

Embodiment 1

[0047] The method for infiltrating and connecting CuW and CuCr materials with high-entropy alloys is specifically implemented according to the following steps:

[0048] Step 1. Weigh the following raw materials according to atomic percentage: Fe 10%, Cu 35%, Cr 35%, Zr 20%, and the sum of the atomic percentages of the above elements is 100%;

[0049] Among them, the particle size of Cu, Cr, Fe, Zr is 400 mesh, and the purity is 99.9%;

[0050] Step 2, adding the raw materials weighed in step 1 and absolute ethanol into a mixer for mixing, mixing evenly to obtain a mixture, placing the mixture in a rigid mold and pressing to obtain a high-entropy alloy green body;

[0051] The ball-to-material ratio for mixing is 30:1, and the mixing time is 12 hours;

[0052] The pressing pressure is 400Mpa, the holding time is 30s, and the height of the high-entropy alloy body is 0.5mm;

[0053] Step 3, process the CuW alloy pre-bonded end flat and clean it, dry it for later use, intercept ...

Embodiment 2

[0061] The method for infiltrating and connecting CuW and CuCr materials with high-entropy alloys is specifically implemented according to the following steps:

[0062] Step 1. Weigh the following raw materials according to atomic percentage: Fe 40%, Cu 5%, Cr 30%, Zr 25%, and the sum of the atomic percentages of the above elements is 100%;

[0063] Among them, the particle size of Cu, Cr, Fe, Zr is 200 mesh, and the purity is 99.9%;

[0064] Step 2, adding the raw materials weighed in step 1 and glycerol into a mixer for mixing, mixing evenly to obtain a mixture, placing the mixture in a rigid mold and pressing to obtain a high-entropy alloy green body;

[0065] The mixing ball-to-material ratio is 20:1, and the mixing time is 8 hours;

[0066] The pressing pressure is 100Mpa, the holding time is 60s, and the height of the high-entropy alloy body is 2mm;

[0067] Step 3, process the CuW alloy pre-bonded end flat and clean it, dry it for later use, intercept the chrome-bronz...

Embodiment 3

[0075] The method for infiltrating and connecting CuW and CuCr materials with high-entropy alloys is specifically implemented according to the following steps:

[0076] Step 1. Weigh the following raw materials according to atomic percentage: Fe 30%, Cu 25%, Cr 5%, Zr 40%, and the sum of the atomic percentages of the above elements is 100%;

[0077] Among them, the particle size of Cu, Cr, Fe, Zr is 50 mesh, and the purity is 99.9%;

[0078] Step 2, adding the raw materials weighed in step 1 and stearic acid into a blender for mixing, mixing evenly to obtain a mixture, placing the mixture in a rigid mold and pressing to obtain a high-entropy alloy green body;

[0079] The ball-to-material ratio for mixing is 10:1, and the mixing time is 8 hours;

[0080] The pressing pressure is 300Mpa, the holding time is 40s, and the height of the high-entropy alloy body is 3mm;

[0081] Step 3, process the CuW alloy pre-bonded end flat and clean it, dry it for later use, intercept the chr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com