Preparation method of nano high-purity carbon

A nano-carbon particle, high-purity technology, applied in the direction of nano-carbon, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low conversion rate and low purity of carbon black, and achieve simple equipment, high purity, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

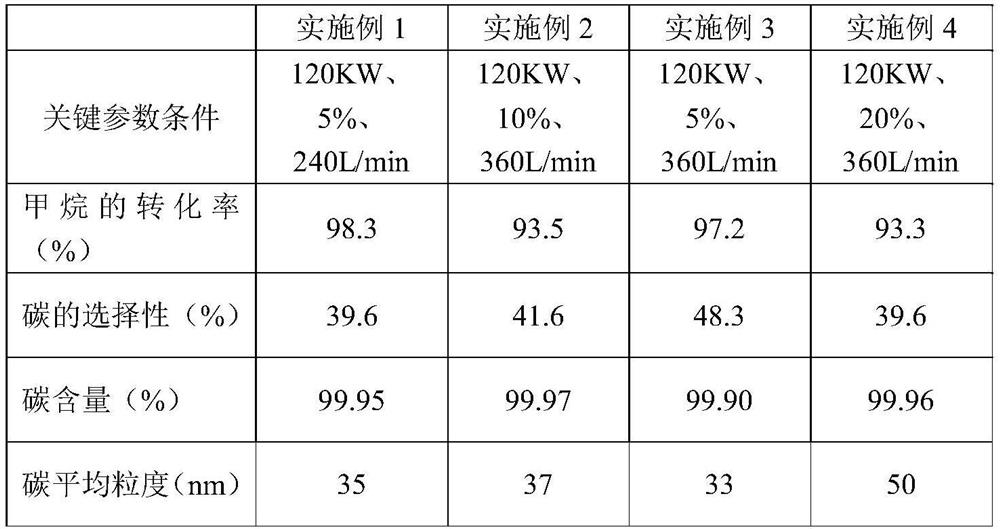

Embodiment 1

[0036] Nitrogen gas is fed into the microwave plasma to form a plasma flame, the microwave plasma power is 120KW, and the nitrogen purity is 99%. Send methane into the plasma flame, and the feeding location is 5.2cm away from the root of the plasma flame. The volume ratio of methane and nitrogen is 5%, and the flow rate of methane and nitrogen is 240L / min. Methane is cracked into carbon nanoparticles in the plasma and collected by an electrostatic precipitator. The effect data of embodiment 1 is shown in table 1.

Embodiment 2

[0038] Nitrogen gas is fed into the microwave plasma to form a plasma flame, the microwave plasma power is 120KW, and the nitrogen purity is 99%. Send methane into the plasma flame, and the feeding location is 5.2cm away from the root of the plasma flame. The volume ratio of methane and nitrogen is 10%, and the flow rate of methane and nitrogen is 360L / min. Methane is cracked into carbon nanoparticles in the plasma and collected by an electrostatic precipitator. The effect data of embodiment 2 is shown in table 1.

Embodiment 3

[0040] Nitrogen gas is fed into the microwave plasma to form a plasma flame, the microwave plasma power is 120KW, and the nitrogen purity is 99%. Send methane into the plasma flame, and the feeding location is 5.2cm away from the root of the plasma flame. The volume ratio of methane and nitrogen is 5%, and the flow rate of methane and nitrogen is 360L / min. Methane is cracked into carbon nanoparticles in the plasma and collected by an electrostatic precipitator. The effect data of embodiment 3 is shown in table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com