Aggregate composite purification carrier

A compound purification and aggregate technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of low removal rate of ammonia nitrogen and total phosphorus, secondary pollution of the environment, etc. Achieve high-efficiency purification function, long life cycle, and beneficial effect of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

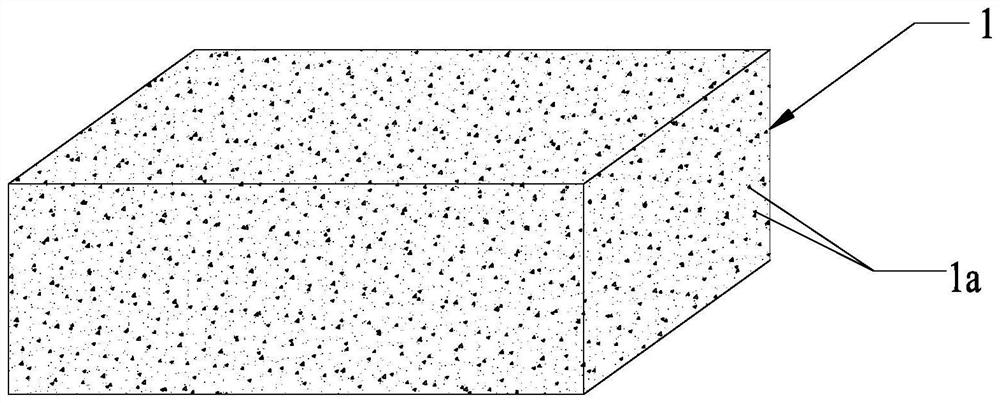

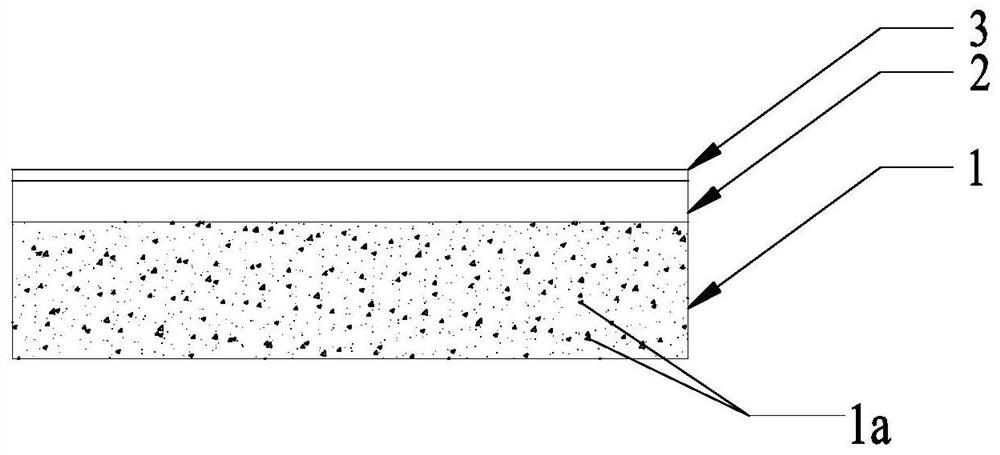

[0015] The embodiment of the present invention provides an aggregate composite purification carrier, such as figure 1 and figure 2 As shown, the aggregate composite purification carrier includes: an aggregate carrier 1, an adhesive layer 2 and a composite bacterial layer 3, the adhesive layer 3 covers the surface of the aggregate carrier 1, and the composite bacterial layer 3 is arranged on the adhesive layer 2 , the composite bacteria in the composite bacteria layer 3 include: COD degrading bacteria and ammonia nitrogen degrading bacteria, adhesive layer 2 includes: polyvinyl alcohol, sodium alginate and gelatin, the concentration ratio of polyvinyl alcohol, sodium alginate and gelatin is 40: 6:1, the thickness of the adhesive layer 2 is 0.01-3 mm, and the weight ratio of the adhesive layer 2 to the composite bacteria layer 3 is 10:1. At the time of realization, the concentrations of polyvinyl alcohol, sodium alginate and gelatin were 80%, 12% and 2%, respectively. Composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com