Low-emissivity (LOW-E) resistant hollow glass

A low-radiation, hollow technology, used in adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problem of insufficient radiation resistance of insulating glass, failure of insulating glass advantages, and service life depends on double-layer glass sealing, etc. problem, to achieve the effect of good weather resistance and aging resistance, good uniformity and performance retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

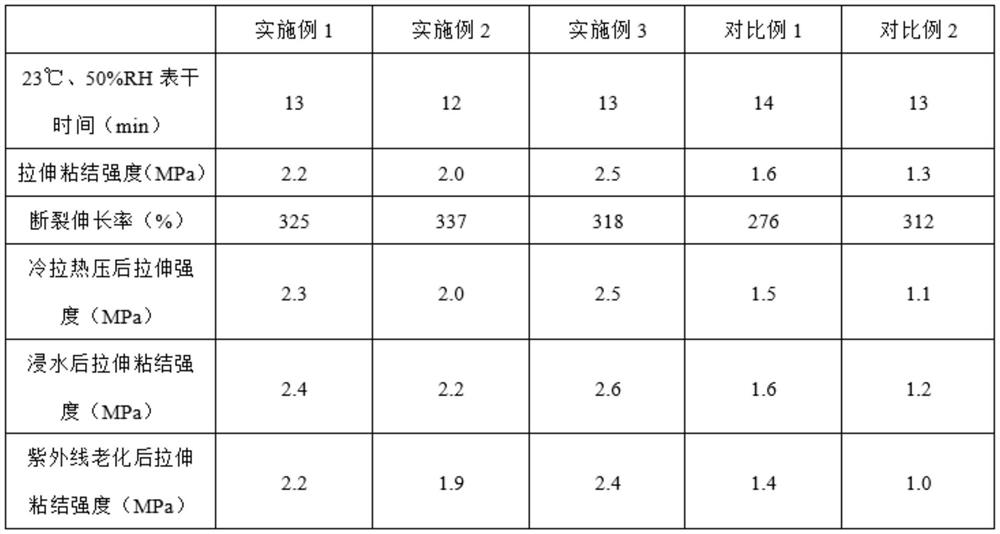

Examples

Embodiment 1

[0041] A low-radiation resistant LOW-E insulating glass, including an aluminum alloy frame and coated glass fixed on both sides of the aluminum alloy frame, wherein the aluminum alloy frame and the two layers of coated glass are sealed structures; the coated glass is coated with Anti-low radiation layer. The sealed structure between the aluminum alloy frame and the two layers of coated glass is filled with rare gas. The anti-low radiation layer includes a zinc borate layer, a first aluminum zinc oxide layer, a metal silver layer, a second aluminum zinc oxide layer, a metal copper layer and an aluminum silicate layer arranged in sequence from the inside to the outside.

[0042] The thickness of the zinc borate layer is 25nm, the thickness of the first aluminum zinc oxide layer is 12nm, the thickness of the metal silver layer is 8nm, the thickness of the second aluminum zinc oxide layer is 20nm, the thickness of the metal copper layer is 17nm, the aluminum silicate layer The th...

Embodiment 2

[0057] A low-radiation resistant LOW-E insulating glass, including an aluminum alloy frame and coated glass fixed on both sides of the aluminum alloy frame, wherein the aluminum alloy frame and the two layers of coated glass are sealed structures; the coated glass is coated with Anti-low radiation layer. The sealed structure between the aluminum alloy frame and the two layers of coated glass is filled with rare gas. The anti-low radiation layer includes a zinc borate layer, a first aluminum zinc oxide layer, a metal silver layer, a second aluminum zinc oxide layer, a metal copper layer and an aluminum silicate layer arranged in sequence from the inside to the outside.

[0058] The thickness of the zinc borate layer is 20nm, the thickness of the first aluminum zinc oxide layer is 10nm, the thickness of the metal silver layer is 5nm, the thickness of the second aluminum zinc oxide layer is 15nm, the thickness of the metal copper layer is 15nm, the aluminum silicate layer The th...

Embodiment 3

[0073] A low-radiation resistant LOW-E insulating glass, including an aluminum alloy frame and coated glass fixed on both sides of the aluminum alloy frame, wherein the aluminum alloy frame and the two layers of coated glass are sealed structures; the coated glass is coated with Anti-low radiation layer. The sealed structure between the aluminum alloy frame and the two layers of coated glass is filled with rare gas. The anti-low radiation layer includes a zinc borate layer, a first aluminum zinc oxide layer, a metal silver layer, a second aluminum zinc oxide layer, a metal copper layer and an aluminum silicate layer arranged in sequence from the inside to the outside.

[0074] The thickness of the zinc borate layer is 30nm, the thickness of the first aluminum zinc oxide layer is 15nm, the thickness of the metal silver layer is 10nm, the thickness of the second aluminum zinc oxide layer is 25nm, the thickness of the metal copper layer is 20nm, the aluminum silicate layer The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com