Method for preparing dispersing agent through ultrasonic-assisted base catalysis of sulfonated pennisetum sinese separation waste liquid degradation product

A technology for separating waste liquid and degradation products, applied in the field of environmentally friendly materials and additives, and fine chemicals, it can solve the problems of low chemical reaction activity and unfavorable modification, and achieve the effects of improving reaction efficiency, reducing energy consumption and improving separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

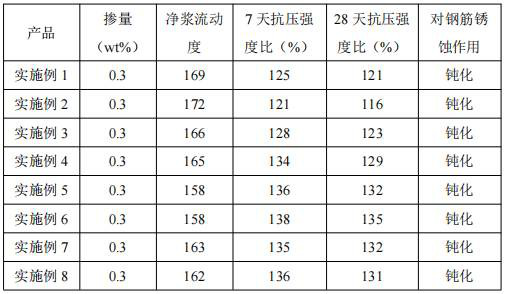

Embodiment 1

[0033] This example provides a kind of preparation method of dispersant, described method comprises the following steps:

[0034] 1) Mix 5.0kg sodium hydroxide, 5.0kg sodium hydrosulfide and 858.0kg distilled water, and stir evenly to obtain a mixed solution;

[0035] 2) Add 100.0kg of dried giant juncao powder and 858.0kg of the mixed solution obtained in step 1) into the ultrasonic reactor, control the power of the ultrasonic reactor to 500W, the frequency to 60kHz, and react at 160°C 3h, after the reaction was completed, the solid residue was removed by filtration to obtain the separation waste liquid of Jujuncao;

[0036] 3) Add 5.0kg of Co / MCM-41 to the separation waste liquid obtained in step 2), and conduct a hydrothermal reaction at 240°C for 3.0 hours. After the reaction is completed, cool to room temperature to obtain the degradation product of separation waste liquid of giant fungus ;

[0037] 4) Add 25.0kg of polycarbonate to the degradation product of the separa...

Embodiment 2

[0040] This example provides a kind of preparation method of dispersant, described method comprises the following steps:

[0041] 1) Mix 20.0kg potassium hydroxide, 20.0kg sodium bisulfite and 819.0kg distilled water, and stir evenly to obtain a mixed solution;

[0042] 2) Add 100.0kg of dried giant juncao powder and 859.0kg of the mixed solution obtained in step 1) into the ultrasonic reactor, control the power of the ultrasonic reactor to 200W, the frequency to 40kHz, and react at 80°C for 0.5 h, after the reaction is finished, the solid residue is removed by filtration, and the separation waste liquid of Jujuncao is obtained;

[0043] 3) Add 10.0kg of Fe / MCM-41 to the waste liquid separated from C. chinensis obtained in step 2), conduct a hydrothermal reaction at 200°C for 4.0 hours, cool to room temperature after the reaction, and obtain the degradation product of the waste liquid separated from C. spp.;

[0044] 4) Add 30.0kg of polycarbonate to the degradation product o...

Embodiment 3

[0047] This example provides a kind of preparation method of dispersant, described method comprises the following steps:

[0048] 1) Mix 5.0kg lithium hydroxide, 20.0kg sodium metabisulfite and 818.5kg distilled water, and stir evenly to obtain a mixed solution;

[0049] 2) Add 100.0kg of dried giant juncao powder and 843.5kg of the mixed solution obtained in step 1) into the ultrasonic reactor, control the power of the ultrasonic reactor to 300W, the frequency to 45kHz, and react at 130°C for 1.5 h, after the reaction is finished, the solid residue is removed by filtration, and the separation waste liquid of Jujuncao is obtained;

[0050] 3) Add 5.0kg of Cu / MCM-41 to the separation waste liquid of Jujuncao obtained in step 2), conduct a hydrothermal reaction at 260°C for 3.0 hours, cool to room temperature after the reaction, and obtain the degradation product of separation waste liquid of Jujuncao;

[0051] 4) Add 50.0kg of polycarbonate to the degradation product of the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com