Electrostatic control method for olefin polymerization process

A technology for olefin polymerization and electrostatic control, applied in the field of olefin polymerization, can solve the problems of poor fluidity, residue, loss of liquid-phase antistatic compound, etc., and achieve the effect of reducing surface resistance and low electrostatic voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

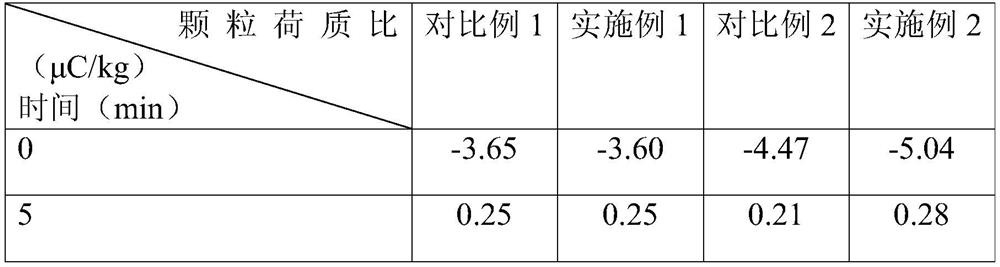

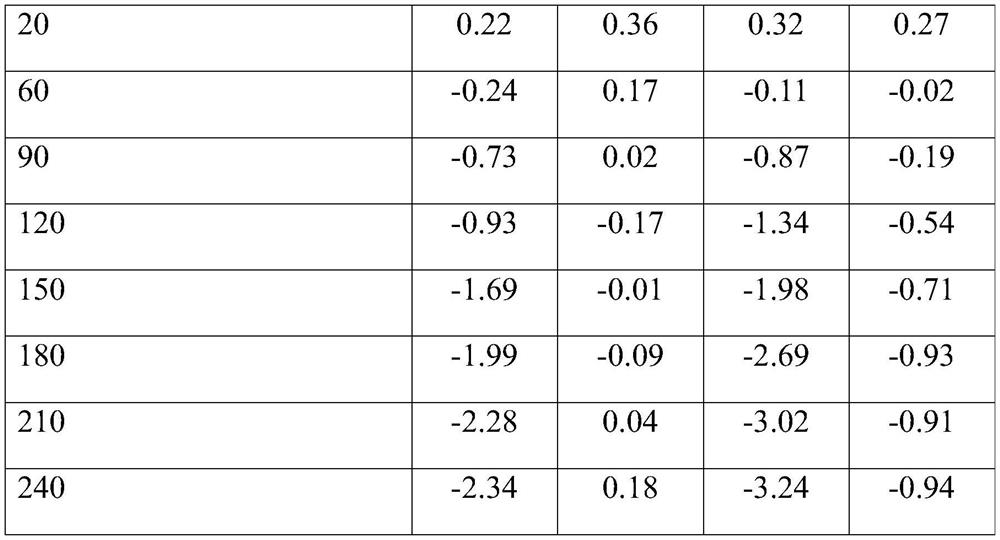

[0041] In Example 1, the polymerization was carried out in a polyethylene bubbling fluidized bed using a metallocene catalyst system, and the antistatic compound used was commercially available under the trademark Atmer 163 (formula R-N(CH 2 CH 2 Oh 2 ) 2 The synthetic mixture of alkyldiethanolamine, wherein R is an alkyl group containing 13 to 15 carbon atoms), is transported at the bottom of the bubbling fluidized bed by means of ethylene pneumatic conveying, with a particle size range of 850-1000 μm and a particle size of 850-1000 μm at 60 The nascent polyethylene powder loaded with antistatic compound at °C was left to stand for 60 hours, and the mass ratio of the amount of antistatic compound relative to the polyethylene powder in the bed was the same as Comparative Example 1, which was 0.02% (200ppm). Wherein, the amount of antistatic compound is 4.0% relative to the weight of nascent polyethylene powder used for loading, and the amount of nascent polyethylene powder l...

Embodiment 2

[0049] In Comparative Example 2, the polymerization was carried out in a circulating fluidized bed of polypropylene using a Ziegler-Natta catalyst system, and the antistatic compound used was commercially available under the trademark Atmer 163 (formula R-N(CH 2 CH 2 Oh 2 ) 2 The synthetic mixture of alkyldiethanolamine, wherein R is an alkyl group containing 13 to 15 carbon atoms), adopts the mode of pneumatic conveying of propylene to convey the particle size range of 850-1000 μm in the middle part of the descending section of the circulating fluidized bed and at 60 The nascent polypropylene powder loaded with antistatic compound at °C was left to stand for 72 hours, and the amount of antistatic compound relative to the weight of the polypropylene powder in the bed was the same as that of Comparative Example 2, which was 0.025% (250ppm). Wherein, the amount of antistatic compound is 2.5% relative to the weight of nascent polypropylene powder for loading, and the amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com