Electric equipment power supply frequency abnormity detection circuit and method

A technology of power supply frequency and electrical equipment, which is applied in the field of abnormal power supply frequency detection circuit of electrical equipment, which can solve problems such as production line stoppage and equipment falsely reporting abnormal power supply frequency, so as to improve accuracy and avoid false alarm of abnormal power supply frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

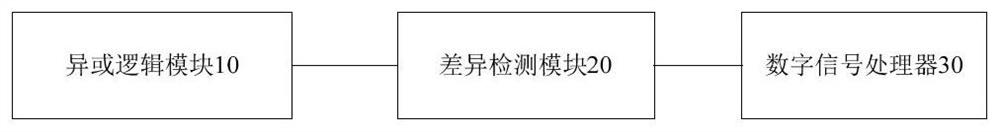

[0061] This embodiment provides a circuit for detecting abnormal power supply frequency of electrical equipment, figure 1 It is a structural block diagram of a power supply frequency abnormal detection circuit for electrical equipment according to an embodiment of the present invention, as shown in figure 1 As shown, the abnormal detection circuit of the power supply frequency of the above-mentioned electrical equipment includes:

[0062] The XOR logic module 10 is used to input the power supply frequency detection signal and a square wave signal with the same frequency and phase as the power supply frequency detection signal, and perform XOR logic processing to generate a sampling signal; wherein, the duty cycle of the above square wave signal is equal to the frequency The duty cycle of the power supply voltage at normal time, for example, if the duty cycle of the power supply voltage is 50% when the frequency is normal, the duty cycle of the above square wave signal is also ...

Embodiment 2

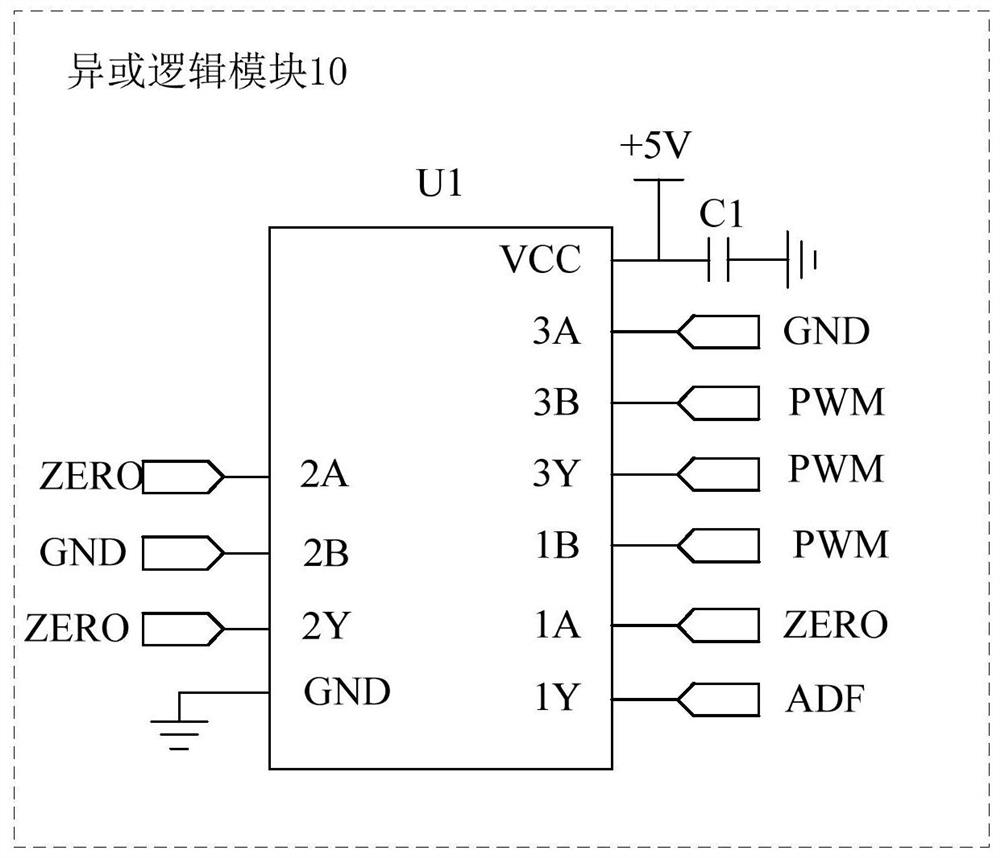

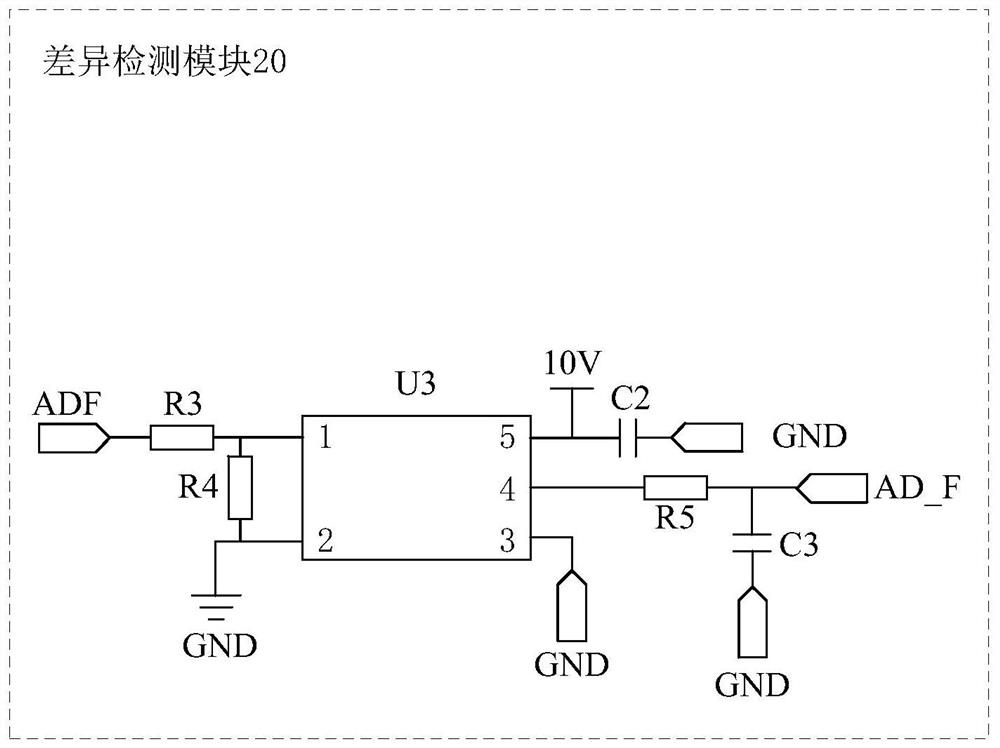

[0067] This embodiment provides another detection circuit for abnormal power supply frequency of electrical equipment, figure 2 is a structural diagram of an XOR logic module according to an embodiment of the present invention, such as figure 2 As shown, the XOR logic module includes:

[0068] The exclusive OR gate chip U1, its first pin Vcc is connected to the first voltage source, one end of its second pin 1A inputs the power supply frequency detection signal ZERO, and the other end is connected to the first exclusive OR gate element inside the exclusive OR gate chip U1 ( not shown in the figure), one end of its third pin 1B inputs a square wave signal PWM, the other end is connected to the second input end of the first XOR gate element, and one end of its fourth pin 1Y is connected to The output end of the first XOR gate element, the other end is connected to the difference detection module 20 for outputting the sampling signal ADF, and its fifth pin GND is grounded; the...

Embodiment 3

[0078] This embodiment provides an electric device, including the above-mentioned abnormal power supply frequency detection circuit of the electric device. In a specific implementation, the electric device is an induction heating device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com