Power semiconductor device and manufacturing method

A technology for power semiconductors and manufacturing methods, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as not being extended to high-voltage and high-power devices, and improve resistance to voltage breakdown. capacity, improved yield, and improved heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, the technical solution will be described in detail by taking a power MOS device as an example in combination with the accompanying drawings.

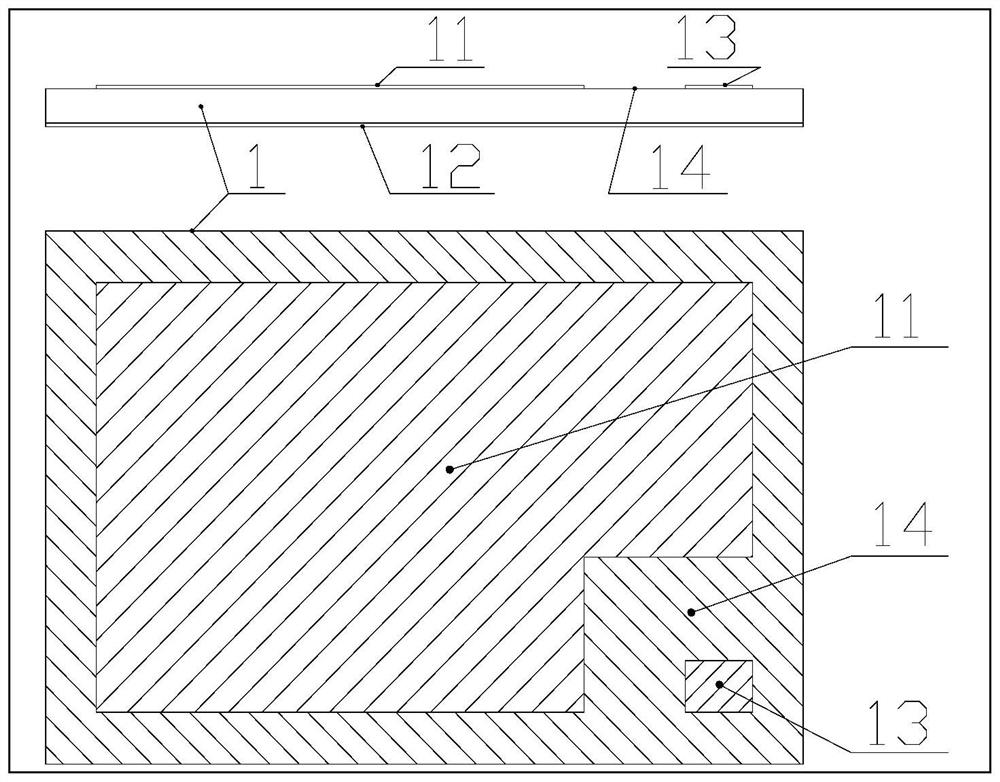

[0040] Power chip design and manufacture such as figure 1 , the power semiconductor device chip, according to the application parameter requirements of the power device, design and manufacture the power chip 1; Drain 12 on the back;

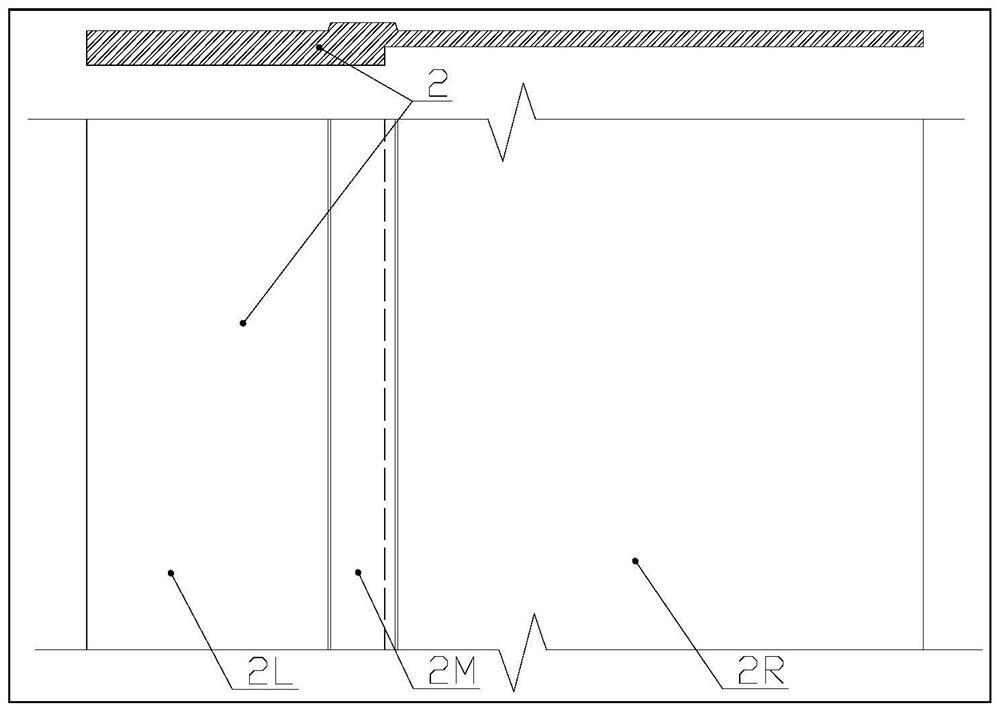

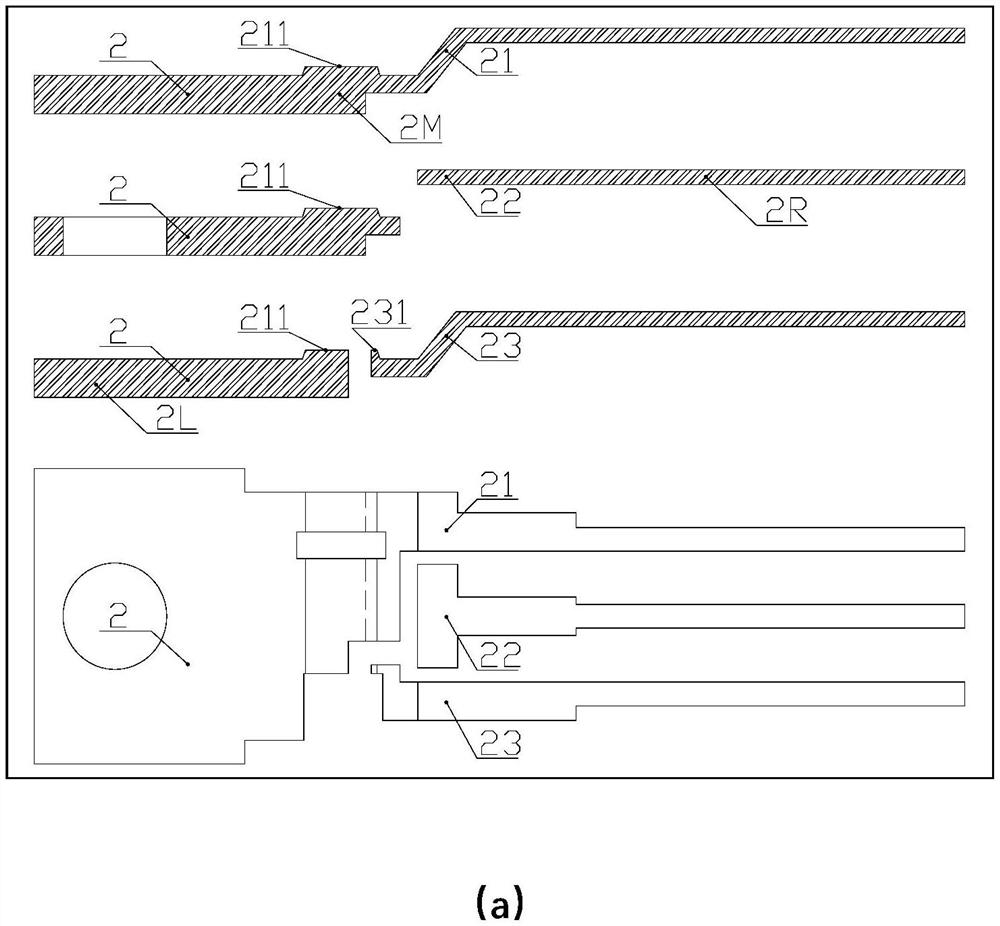

[0041] The source electrode 11 of the power chip is directly welded to the package frame 2, and is attached to the raised package copper frame and the chip source metal welding area 211. After welding, the source electrode connection is formed, and the heat generated by the chip 1 passes through the source electrode 11 and passes through the package frame. 2 Conduction to dissipate heat outward;

[0042] The drain 12 of the power chip is welded to the package frame 2 by wire bonding or CLIP jumper, and is connected to the drain pin 22 of the package copper frame;

[0043] The power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com