Thickening agent having fine particle structure with improved feeling of use

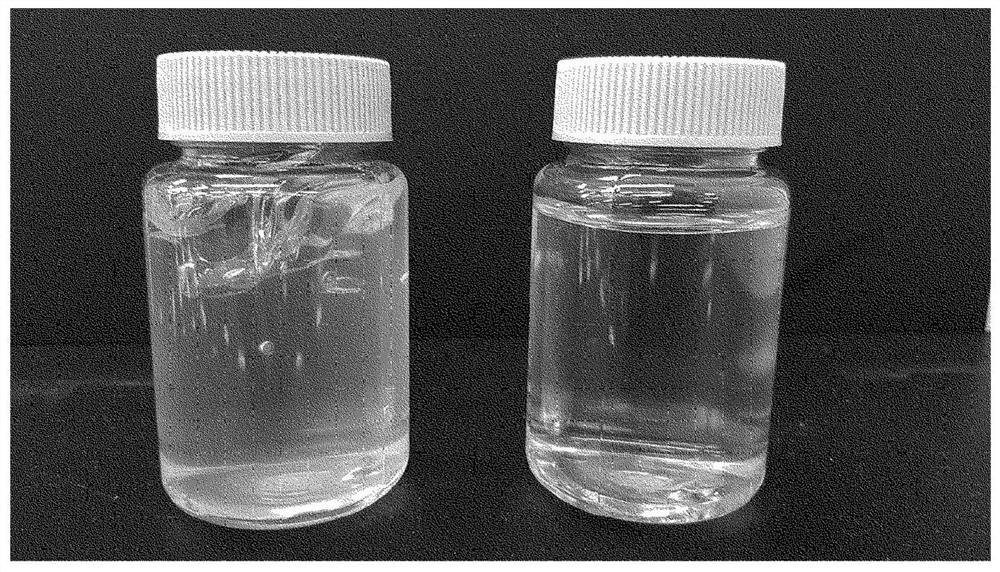

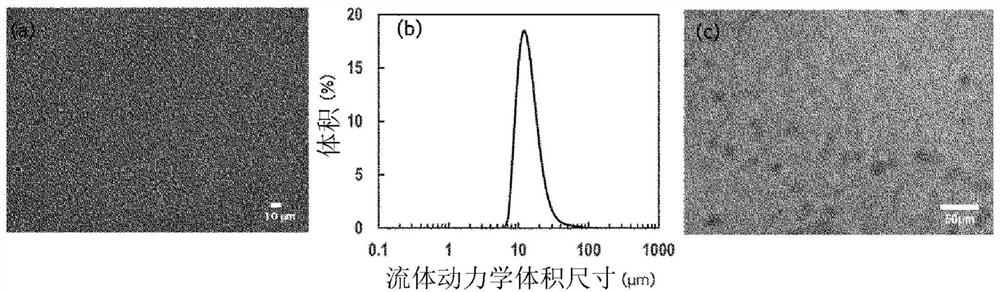

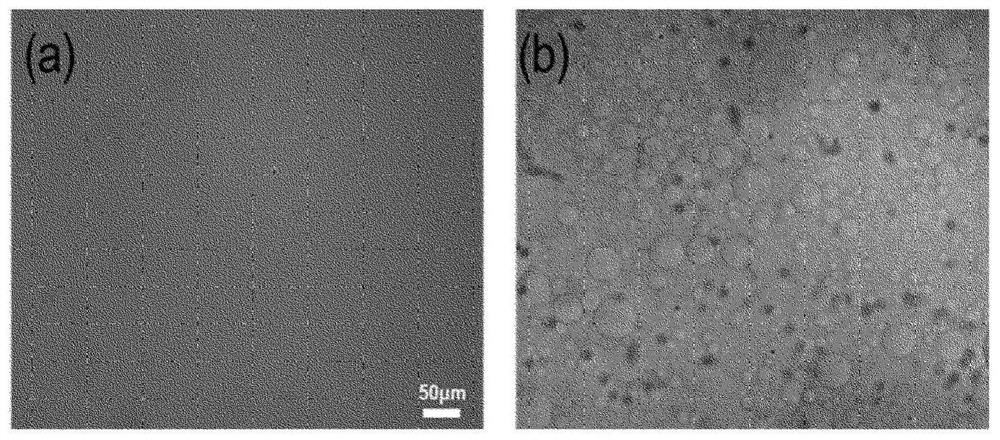

A technology of thickener and surfactant, applied in the field of thickener, can solve the problems of difficult application of transparent dosage forms, opacity of thickener, etc., and achieve the effect of transparent appearance, uniform particle dispersion, and improved smearability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention relates to a kind of preparation method of thickener, it comprises:

[0026] (1) A step of preparing an oil-in-water emulsion composition comprising an aqueous phase comprising a compound represented by the following Chemical Formula 1 and a crosslinking monomer and comprising a solubility parameter (solubility parameter) of 15(MPa) 1 / 2 The oil phase of the above non-polar organic solvent;

[0027] (2) a step of heating to above 60° C. to prepare a water-in-oil type inverse emulsion composition; and

[0028] (3) A step of preparing a crosslinked polymer by adding a reaction initiator to carry out a polymerization reaction.

[0029] [chemical formula 1]

[0030]

[0031] Next, the configuration of the present invention will be specifically described.

[0032] In the present invention, the thickener is prepared by PIT (phase inversion temperature) polymerization method.

[0033] Specifically, in the present invention, the solubility coefficie...

Embodiment approach

[0071] Hereinafter, the present invention will be described in detail by way of examples. The following examples are only for illustrating the present invention, and the scope of the present invention is not limited to the following examples. The present embodiment is provided to complete the disclosure of the present invention and to fully inform the scope of the invention to those skilled in the art to which the present invention pertains, and the present invention is defined only by the scope of claims.

Embodiment 1

[0076] Water phase: Dissolve 17g of 2-acrylamido-2-methylpropanesulfonic acid and 0.5g of trimethylolpropane ethoxylate triacrylate in 63g of distilled water, then wash with ammonia (Ammonia) Neutralize to pH 7-9 in water.

[0077] Oil phase: Put 10g of polyoxyethylene (3) oleyl ether and polyoxyethylene (6) oleyl ether (Polyoxyethylene (6) oleylether) in 80g of heptane (Hepane) and mix well.

[0078] Put the water phase and oil phase into the reactor and heat to 70°C, then put 0.1g initiator 4,4'-azobis (4-cyanovaleric acid), react for 3 hours, use acetone to precipitate the thickener to get.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com