Method for preparing low-sodium ZSM-5 molecular sieve and application of low-sodium ZSM-5 molecular sieve in xylene isomerization catalyst

A technology of ZSM-5 and molecular sieve, which is applied in molecular sieve catalysts, physical/chemical process catalysts, isomerization hydrocarbon production, etc., can solve the problems of xylene yield loss, process selectivity decline, high side reactions, etc., to reduce Production cost, improvement of isomerization activity, and effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

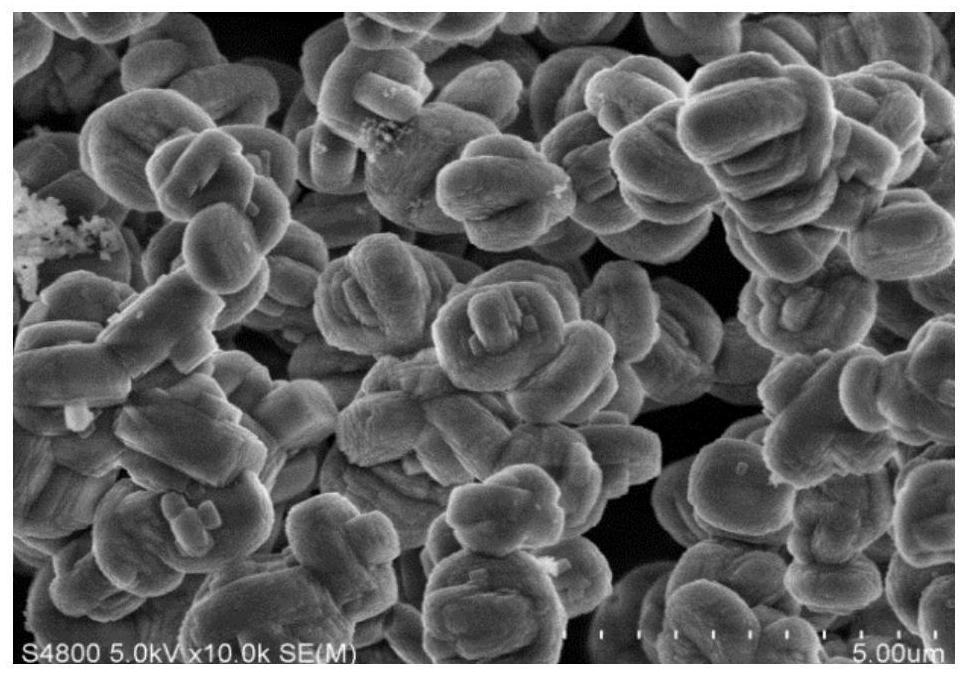

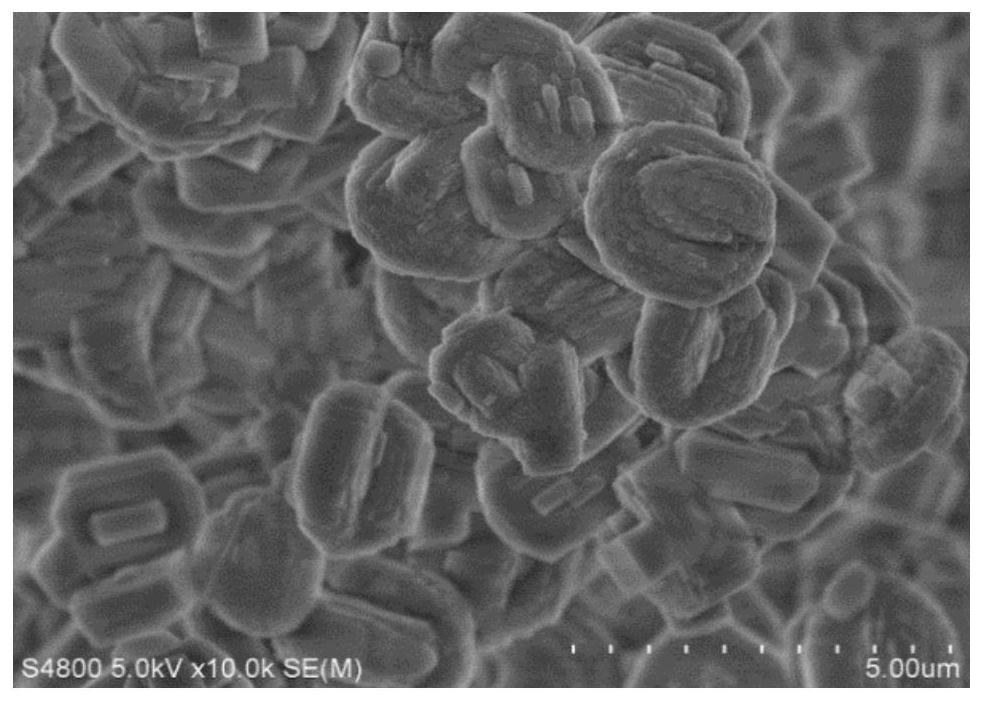

[0043] Adding a dispersant to the method for preparing low-sodium ZSM-5 molecular sieve of the present invention can optimize the morphology and surface acid distribution of the prepared molecular sieve, thereby improving the isomerization activity of the catalyst and obtaining higher p-xylene absorption. At the same time, the catalyst prepared by the method of the present invention can be used to prepare the catalyst without the ammonium exchange of the ZSM-5 molecular sieve, which not only reduces the discharge of nitrogen-containing wastewater, reduces the cost of catalyst preparation, but also reduces the pressure on environmental protection.

[0044] In one embodiment according to the present invention, the molar ratio of each material in the mixture to be crystallized is Na 2 O: SiO 2 :Al 2 o 3 :T:DA:H 2 O=(0.2-0.4): 1: (0.006-0.02): (0.01-0.12): (0.03-0.3): (20-50); wherein, sodium oxide / silicon oxide in the water glass described in (1) step The molar ratio is (2-4)...

Embodiment approach

[0059] In one embodiment, the shaped carrier loaded with the platinum component can be further subjected to steps such as drying, calcination under air atmosphere, and reduction. The temperature of the calcination can be preferably 400-550°C, hydrogen is preferably used as the reducing gas for the reduction, and the reduction temperature is 400-550°C, preferably 450-520°C.

[0060] The catalyst prepared by the present invention can be applied to 8 Xylene isomerization reaction of aromatic hydrocarbons, the isomerization reaction conditions can be: temperature 320-400°C, preferably 360-380°C, pressure 0.1-1.2MPa, preferably 0.2-1.1MPa, hydrogen / hydrocarbon molar ratio 0.2 -4.0, preferably 0.5-3.0, feed quality space velocity 4.0-15.0 hours -1 , preferably 6.0-12.0h -1 .

[0061] The present invention is further illustrated below by examples, but the present invention is not thereby limited in any way.

[0062] In the following examples and comparative examples of the presen...

example 1

[0067] (1) Preparation of low-sodium ZSM-5 molecular sieve

[0068] Add 58.5g water glass (SiO 2 The content is 24.01% by mass, Na 2 O content is 7.08% by mass, Al 2 o 3 Content is 0.2 mass %, the same below), 0.31g aluminum sulfate octadecahydrate, 2.33g tetraethylammonium chloride N (C 2 h 5 ) 4 + Cl - As template agent (T), 1.4g isopropanol, 64.8g deionized water mix homogeneously, obtain the mixture to be crystallized; Wherein the molar ratio of each material is Na 2 O: SiO 2 :Al2 o 3 :T:DA:H 2 O=0.28:1:0.007:0.06:0.1:25. Isopropanol is a dispersant.

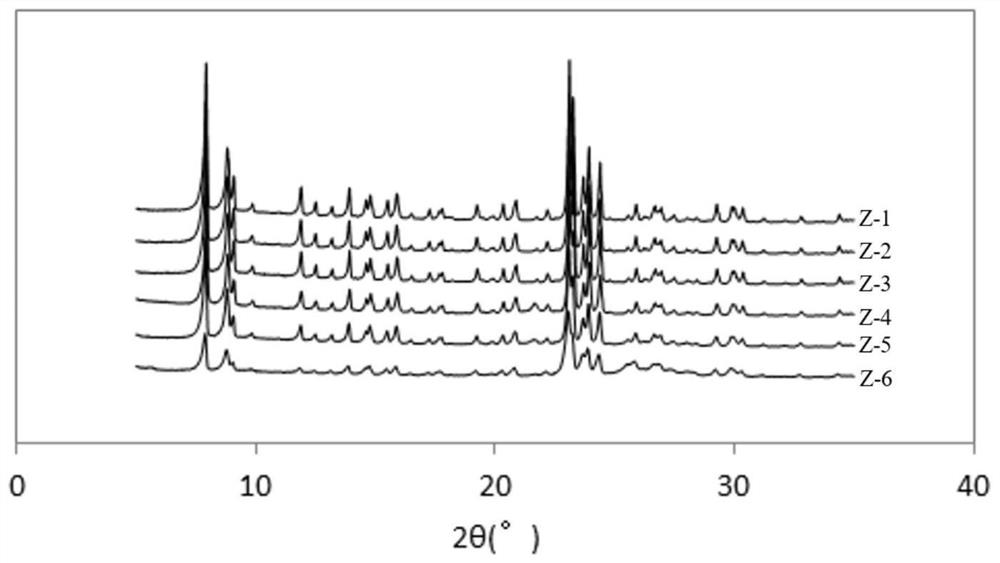

[0069] The mixture to be crystallized was hydrothermally crystallized at 175°C for 35 hours, and the solid obtained after crystallization was washed with excess deionized water until the pH value of the eluate was 6-8, which was neutral, and then dried at 120°C for 6 Hours, low-sodium ZSM-5 molecular sieve was obtained, denoted as Z-1, its silica / alumina molar ratio was 100, Na 2 The O content is 0.45mol% (meas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com