Supported metal catalyst for olefin isomerization reaction and preparation method thereof

A technology for olefin isomerization and metal loading, which is used in isomerization to produce hydrocarbons, carbon compound catalysts, catalysts for physical/chemical processes, etc. problems, to achieve the effects of long single-pass operation cycle, solving carbon deposition and coking, and solving isomerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

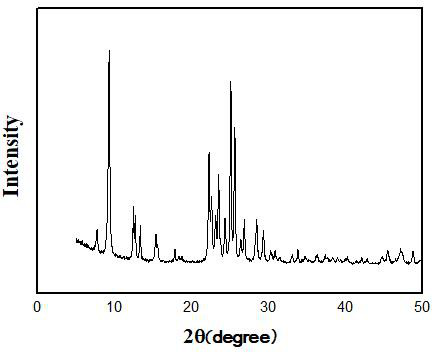

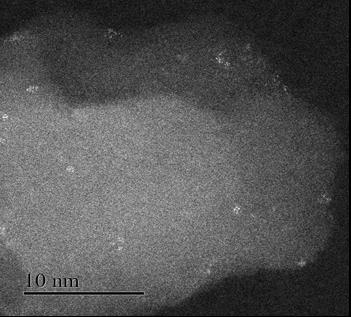

Image

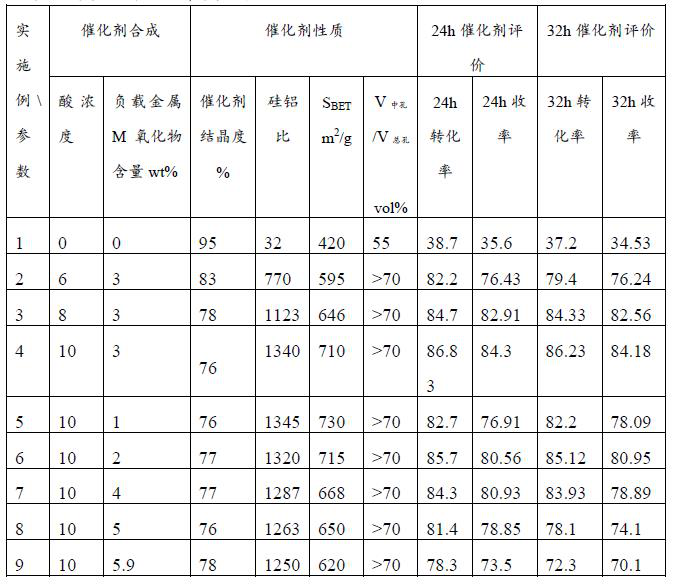

Examples

preparation example Construction

[0080] The specific preparation conditions and reactant ratios in the preparation method of the present application are not limited, as long as the target product can be formed. In some embodiments of the method, in step c, the ammonium salt is one or more of ammonium chloride, ammonium sulfate and ammonium nitrate; the ammonium exchange condition is molecular sieve, The weight ratio of ammonium salt to water is 1:(0.1-1):(5-10), the temperature is from room temperature to 100°C, and the time is 0.2-4 hours; the total dry basis weight of molecular sieves is calculated as sodium oxide and ammonium exchanged As a basis, the sodium content of the ammonium exchanged molecular sieve is less than 0.2 wt%.

[0081] In some embodiments of the method, in step e, the acid in the acid treatment process is selected from one or more of hydrochloric acid, nitric acid, sulfuric acid, citric acid and hydrofluoric acid; the concentration range of the acid used is 4 ~12 mol / L, the volume ratio...

Embodiment 1

[0132] (1) Preparation of Catalyst 1

[0133] A kind of synthetic method of silicon aluminum type molecular sieve, comprises the following steps:

[0134] First crystallization step a

[0135] Put silica gel, sodium aluminate, sodium hydroxide, ethylenediamine, and water in a crystallization kettle with a molar ratio of 1:0.15:0.07:0.3:35 and mix evenly. Crystallize at 130°C for 32 hours, and crystallize at 180°C for 65 Hours, to obtain crystallized silicon aluminum type molecular sieve slurry;

[0136] First cleaning step b

[0137] Filter the mother liquor from the crystallized silicon-aluminum molecular sieve slurry obtained in step a, and wash with water until Na 2 The O content (on a dry basis) is less than 2 wt%, filtered and dried to obtain a Na-type molecular sieve (also known as a water-washed molecular sieve), that is, catalyst 1.

[0138] The crystallinity, silicon-aluminum ratio, supported metal content, specific surface area, pore volume, sodium content, metal...

Embodiment 2

[0141] The preparation of catalyst 2 can be obtained by further processing catalyst 1 in embodiment 1, specifically as follows:

[0142] First ammonium exchange step c

[0143] Add 100g of catalyst 1 raw powder (dry basis) to 800g of water for beating, add 40g of NH 4 Cl, heated to 80 °C, exchanged for 1 h, to Na 2 The O content (on a dry basis) is lower than 0.2wt%, filtered and washed to obtain a molecular sieve filter cake;

[0144] first roasting step d

[0145] After drying the filter cake obtained in step c, it is roasted at 550° C. in an air atmosphere for 4 h;

[0146] Dealumination step e

[0147] Weigh 10.0 g of the roasted product obtained in step d and add 200 mL of HNO 3 solution, the concentration of the acid solution is 6mol / L, the temperature is raised to 100°C and the stirring is continued for 8 h, the liquid is cooled to room temperature and filtered, washed with deionized water until neutral, and the filter cake is dried.

[0148] Secondary crystalliza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com