Oil well cement dispersing agent as well as preparation method and application thereof

A technology for oil well cement and dispersant, which is applied to the field of oil well cement dispersant and its preparation and application, can solve the problems of low dispersant efficiency, polluted polycarboxylate dispersant, and low temperature resistance, so as to improve flow performance and avoid production Accidents, the effect of improving dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

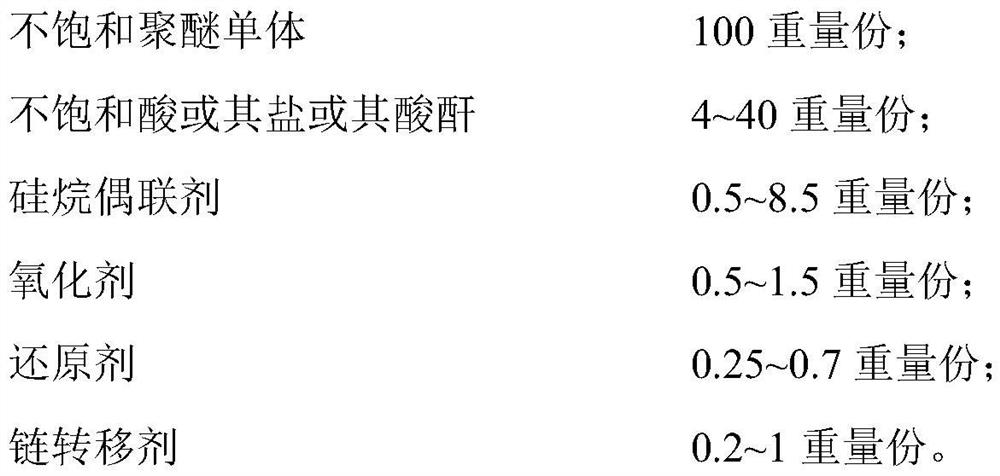

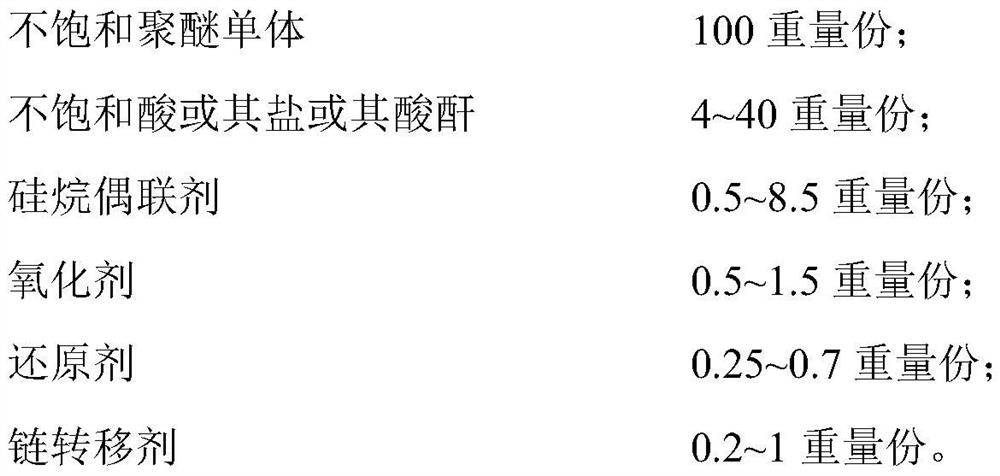

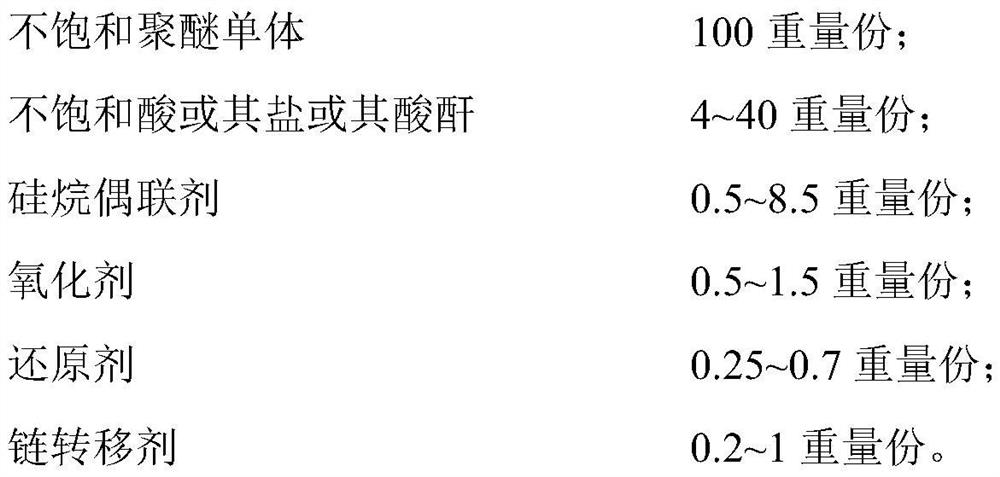

Method used

Image

Examples

Embodiment 1

[0074] 100 g of TPEG 2400 and 150 g of deionized water were added to a round bottom flask, stirred and heated to 70°C. Add 1.5g of hydrogen peroxide into 15g of deionized water, stir well and add to the reaction kettle. 0.7g ascorbic acid and 1g of 3-mercaptopropionic acid were added into 17g deionized water to make a mixed aqueous solution of reducing agent and chain transfer agent; 40g acrylic acid (AA) was added to 40g deionized water to make an aqueous solution of acrylic acid; The aqueous solution of acrylic acid solution, 0.5g of KH-570 and acrylic acid solution were added dropwise into the round bottom flask at the same time, and the addition of the aqueous solution of acrylic acid and KH-570 was controlled by a peristaltic pump in 4 hours, and the mixed solution of reducing agent and chain transfer agent was dropped in 4.5 hours. Finished adding. After all the materials were added dropwise, the heat preservation and stirring were continued for 0.5 hour to prepare samp...

Embodiment 2

[0076]Add 100 g of methallyl alcohol polyoxyethylene ether and 160 g of deionized water into a round bottom flask, stir and heat to 50°C. Add 0.5 g of hydrogen peroxide into 5 g of deionized water, stir well and add to the reaction kettle. The 3-mercaptopropionic acid of 0.25g ascorbic acid and 0.2g is added into 5.5g deionized water to make reducing agent and chain transfer agent mixed aqueous solution; 4g itaconic acid (IA) is added into 4g deionized water to make itaconic acid aqueous solution; The reducing agent and chain transfer agent mixed aqueous solution, 8.5g of KH-550, and itaconic acid aqueous solution were added dropwise to the round bottom flask at the same time, and the itaconic acid aqueous solution and KH-550 were controlled by a peristaltic pump to be added dropwise in 2 hours. The aqueous solution mixed with the chain transfer agent was added dropwise in 2.5 hours. After all the materials were added dropwise, the heat preservation and stirring were continue...

Embodiment 3

[0078] A round bottom flask was charged with 100 g of HPEG 4000 and 150 g of deionized water, stirred and heated to 65°C. Add 0.9 g of hydrogen peroxide into 4.5 g of deionized water, stir well and add to the reaction kettle. The 3-mercaptopropionic acid of 0.35g ascorbic acid and 0.8g is added into 11.5g deionized water and made reductive agent and chain transfer agent mixed aqueous solution; 24g acrylic acid (AA) is added into 24g deionized water and made acrylic acid aqueous solution; Reductive agent and The chain transfer agent mixed aqueous solution, 5g of KH-570, and acrylic acid aqueous solution were dropped into the round bottom flask at the same time, and the acrylic acid aqueous solution and KH-570 were added dropwise through the peristaltic pump in 3 hours, and the reducing agent and chain transfer agent mixed aqueous solution was dropped in 3.5 hours. Finished adding. After all the materials were added dropwise, the heat preservation and stirring were continued fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com