Thermal response polyion liquid hydrogel for brine desalination

A polyionic liquid and brine desalination technology, which is applied in the field of thermally responsive polyionic liquid hydrogel, can solve the problems of reduced desalination effect, insignificant volume shrinkage, and water extrusion that cannot be desalinated, so as to improve the desalination effect, Avoid the effects of high energy consumption and high brine desalination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

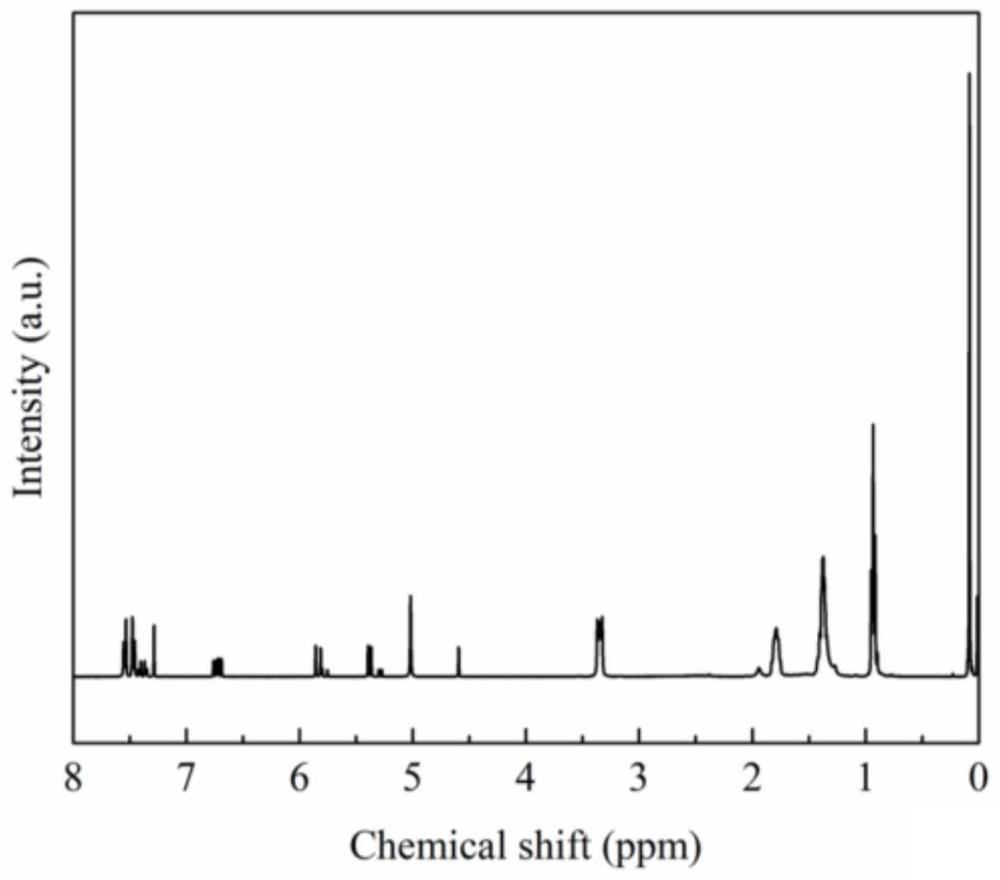

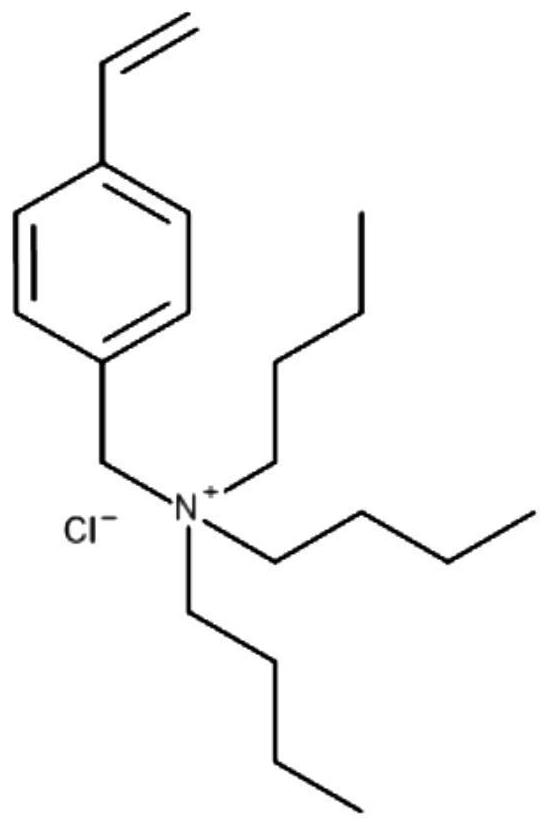

[0032] The ionic liquid monomer was synthesized from 1,4-vinylbenzyl chloride (A) and tripentylamine (B).

[0033] The first step is to synthesize the ionic liquid monomer. Pour 50ml of acetonitrile into a 200ml three-neck flask, then add 13.76g (58mmol) of tripentylamine and 10.1g (60mmol) of 1,4-vinylbenzyl chloride, stir at room temperature for 40 hours, remove the acetonitrile after the reaction, and wash with ether Three times of product, then remove the ether and dry the product in a vacuum oven at room temperature to obtain the tripentylamine-vinylbenzyl chloride ionic liquid monomer;

[0034] The second step is to polymerize and crosslink the ionic liquid monomer. The initiator adopts azobisisobutyronitrile (AIBN), and the crosslinking agent adopts polyethylene glycol dimethacrylate (Mn=550g / mol); the ionic liquid monomer synthesized in the first step of 10g is dissolved in 40g anhydrous In ethanol, add initiator and cross-linking agent, stir evenly to a colorless tr...

Embodiment 2

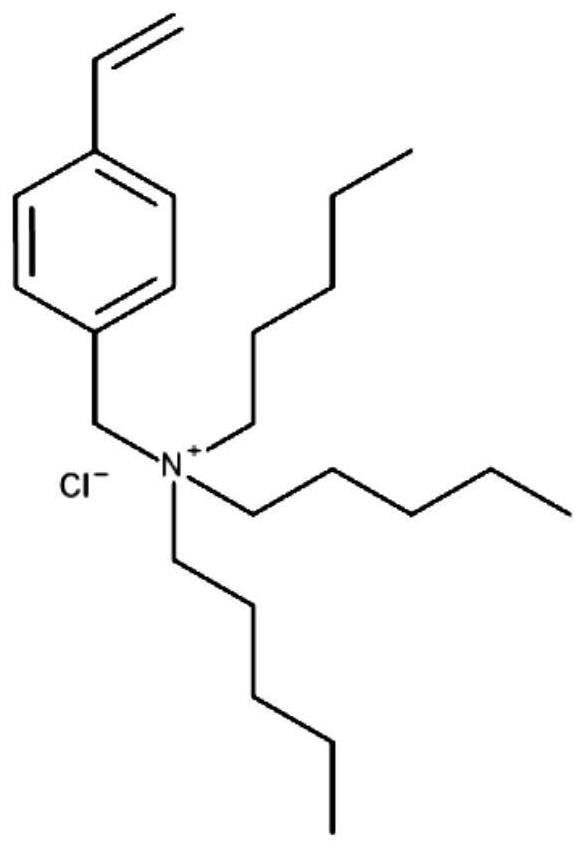

[0036] The ionic liquid monomer is synthesized by 1,4-vinylbenzyl chloride (A) and tributylamine (B). During gel synthesis, monomer: initiator: crosslinking agent = 100:1:0.1 (molar ratio), synthesized Ionic liquid monomer, ionic liquid monomer polymerization cross-linking method is the same as embodiment 1; Monomer structural formula is as figure 2 shown.

Embodiment 3

[0038] The ionic liquid monomer is synthesized by 1,3-vinylbenzyl bromide (A) and trihexylphosphine (B). During gel synthesis, monomer: initiator: crosslinking agent = 100:1:0.1 (molar ratio), synthesized Ionic liquid monomer, ionic liquid monomer polymerization cross-linking method is the same as embodiment 1; Monomer structural formula is as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com