Solar heat collecting tube, preparation method of solar heat collecting tube and testing method of solar heat collecting tube

A solar heat collecting tube and solar energy technology, which is applied in the parts of solar heat collectors, solar thermal energy, solar heat collectors, etc., can solve the problems of not easy to degrade, low service life of solar heat collecting materials, low energy conversion rate, etc. To achieve the effect of alleviating the rapid loss of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a kind of preparation method of solar heat collecting tube, and this preparation method comprises the following steps:

[0045] (1) According to the mass ratio of 1:133, the dispersant is dissolved in deionized water, heated to a temperature of 45-65°C, and prepared into a dispersed phase; n-octadecane, styrene monomer, divinylbenzene mono Stir the body, initiator and nano-silicon carbide particles at a temperature of 45-65°C for 15-30 minutes to form an oil phase;

[0046](2) At the same temperature of the dispersed phase and oil phase two-phase system, add the oil phase to the dispersed phase according to the volume ratio of 1:10-1:15, stir and emulsify at a speed of 500-1000rpm for 15-30min, and then Raise the temperature to 75-90°C, and continue to stir for 3-6 hours; after the reaction, filter, wash, and dry to obtain a styrene-divinylbenzene copolymer / SiC composite shell microencapsulated phase change material;

[0047] (3), th...

Embodiment 1

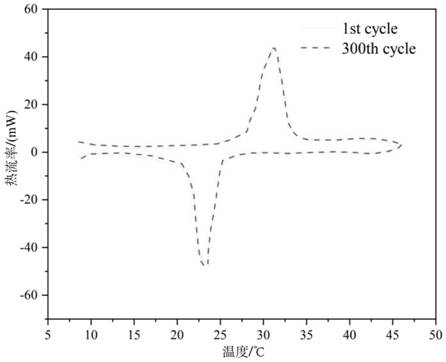

[0071] In the embodiment, the phase change microcapsule material filled in the annular glass region does not add nano-silicon carbide particles.

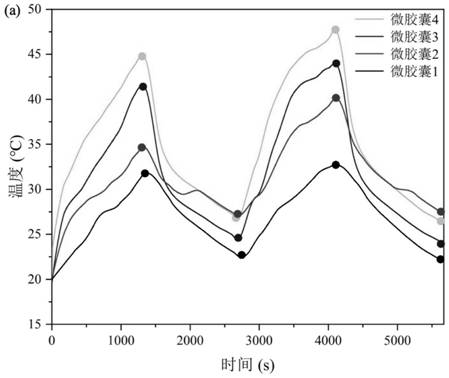

[0072] The prepared phase change microcapsules are suction filtered, washed and dried while hot. After suction filtration, the obtained product was dried in an oven at 60° C. until constant weight. The phase-change microcapsule material is evenly filled in the annular glass regions of two glass tubes of equal length and different diameters. When filling, the nozzles of the two glass tubes are placed vertically upwards and the center lines coincide. Use a needle syringe to slowly inject water fluid into the inner glass tube of the solar collector tube until it is full. The solar heat source lamp was used for heating treatment at room temperature (25° C.) for 23 minutes, and then natural cooling treatment was carried out at room temperature (20° C.) for 23 minutes, as a cooling and heating cycle. The whole test process consists of ...

Embodiment 2

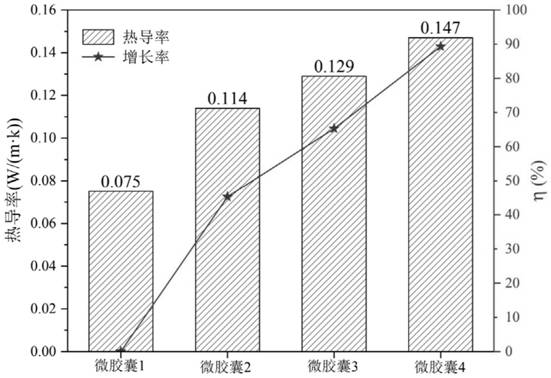

[0075] In the phase-change microcapsule material filled in the ring-shaped glass area in the embodiment, the nano-silicon carbide particles in the filled phase-change microcapsule material account for 1.5% of the mass of styrene monomer.

[0076] The prepared phase change microcapsules are suction filtered, washed and dried while hot. After suction filtration, the obtained product was dried in an oven at 60° C. until constant weight. The phase-change microcapsule material is evenly filled in the annular glass regions of two glass tubes of equal length and different diameters. When filling, the nozzles of the two glass tubes are placed vertically upwards and the center lines coincide. Use a needle syringe to slowly inject water fluid into the inner glass tube of the solar collector tube until it is full. The solar heat source lamp was used for heating treatment at room temperature (20° C.) for 23 minutes, and then natural cooling treatment was carried out at room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Phase change enthalpy | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com