Process for preparing high-purity phosphoric acid by decoloring denitrified and impurity-removed phosphoric acid

A high-purity, phosphoric acid technology, applied in the direction of phosphoric acid, phosphorus oxyacids, phosphorus compounds, etc., can solve problems affecting the decolorization process, etc., and achieve the effect of improving removal efficiency, improving utilization rate, and increasing formation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

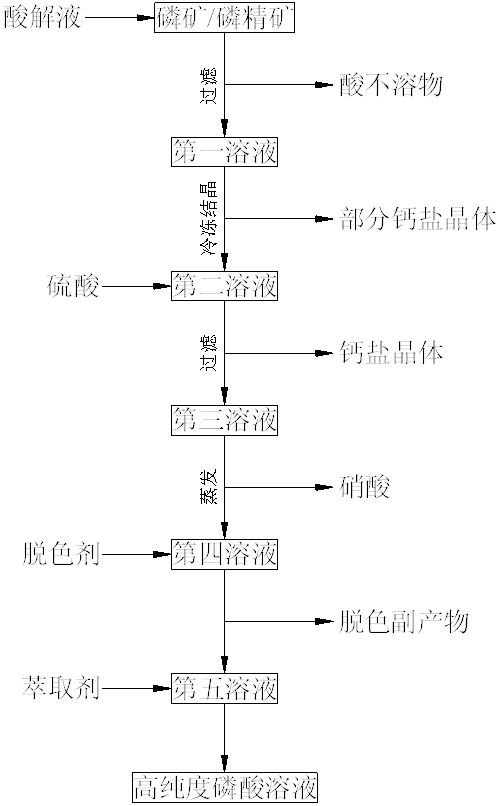

[0038] A kind of process that the present invention proposes decolorizes denitrified and impurity-removed phosphoric acid to prepare high-purity phosphoric acid. The method steps are as follows:

[0039] S1: Decompose phosphate rock / phosphate concentrate by acid hydrolysis solution;

[0040] S2: Filter the solution decomposed in S1 to remove acid insoluble matter to obtain the first solution;

[0041] S3: Freezing and crystallizing the first solution in S2 to remove part of the calcium salt crystals to obtain a second solution;

[0042] S4: adding sulfuric acid to the second solution of the solution in S3 and filtering to remove calcium to obtain a third solution;

[0043] S5: Evaporating the third solution in S4 to remove nitric acid in the solution to obtain a fourth solution;

[0044] S6: adding a decolorizing agent to the fourth solution in S5 for decolorization treatment to obtain a decolorized by-product and a fifth solution;

[0045] S7: Adding the first extractant t...

Embodiment 2

[0054] A kind of process that the present invention proposes decolorizes denitrified and impurity-removed phosphoric acid to prepare high-purity phosphoric acid. The method steps are as follows:

[0055] S1: Decompose phosphate rock / phosphate concentrate by acid hydrolysis solution;

[0056] S2: Filter the solution decomposed in S1 to remove acid insoluble matter to obtain the first solution;

[0057] S3: Freezing and crystallizing the first solution in S2 to remove part of the calcium salt crystals to obtain a second solution;

[0058] S4: adding sulfuric acid to the second solution of the solution in S3 and filtering to remove calcium to obtain a third solution;

[0059] S5: Evaporating the third solution in S4 to obtain a fourth solution;

[0060] S6: adding a decolorizing agent to the fourth solution in S5 for decolorization treatment to obtain a decolorized by-product and a fifth solution;

[0061] S7: Adding the first extractant to the fifth solution in S6 for extract...

Embodiment 3

[0070] A kind of process that the present invention proposes decolorizes denitrified and impurity-removed phosphoric acid to prepare high-purity phosphoric acid. The method steps are as follows:

[0071] S1: Decompose phosphate rock / phosphate concentrate by acid hydrolysis solution;

[0072] S2: Filter the solution decomposed in S1 to remove acid insoluble matter to obtain the first solution;

[0073] S3: Freezing and crystallizing the first solution in S2 to remove part of the calcium salt crystals to obtain a second solution;

[0074] S4: adding sulfuric acid to the second solution of the solution in S3 and filtering to remove calcium to obtain a third solution;

[0075] S5: Evaporating the third solution in S4 to obtain a fourth solution;

[0076] S6: adding a decolorizing agent to the fourth solution in S5 for decolorization treatment to obtain a decolorized by-product and a fifth solution;

[0077] S7: Adding the first extractant to the fifth solution in S6 for extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com