A kind of preparation method of graphitized porous carbon for the removal of soil and musty substances

A technology of graphitization and porous carbon, applied in chemical instruments and methods, inorganic chemistry, water pollutants, etc., can solve the problems of low removal efficiency of activated carbon, limited adsorption capacity, long adsorption process, etc., and achieve excellent adsorption removal effect, Effect of increased pore volume and shortened impregnation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

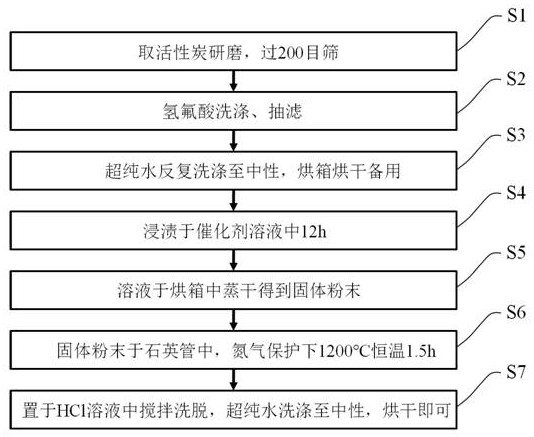

[0042] A kind of preparation of graphitized porous carbon (its process flow is as follows: figure 1 shown):

[0043] S1, select each 50g powder activated carbon of coconut shell, wood and coal, grind with a ball mill and agate mortar, and pass through a 200-mesh sieve;

[0044] S2, pickling, with 0.10mol·L -1 The hydrofluoric acid solution is washed and suction filtered, and the washing and suction filtration operations are repeated twice before the end;

[0045] S3, washing and drying, repeatedly washing the acid-washed activated carbon with ultrapure water until it is neutral, and placing it in an oven, drying at 105° C. for 12 hours, and sealing and storing it for later use;

[0046] S4, impregnation treatment, 5 g of the activated carbon obtained in step S3 is impregnated in Fe(NO) at a ratio of 3 mmol / g 3 ) 3 •9H 2 In O catalyst solution, immersion for 12h;

[0047] S5, curing treatment, placing the solution obtained in step S4 in an oven, drying at 105° C. for 12 h...

Embodiment 2

[0051] A kind of preparation of graphitized porous carbon:

[0052] S1, select each 50g powder activated carbon of coconut shell, wood and coal, grind with a ball mill and agate mortar, and pass through a 200-mesh sieve;

[0053] S2, pickling, with 0.10mol·L -1 The hydrofluoric acid solution is washed and suction filtered, and the washing and suction filtration operations are repeated twice before the end;

[0054] S3, washing and drying, repeatedly washing the acid-washed activated carbon with ultrapure water until it is neutral, and placing it in an oven, drying at 105° C. for 12 hours, and sealing and storing it for later use;

[0055] S4, impregnation treatment, 5 g of the activated carbon obtained in step S3 is impregnated in Fe(NO) at a ratio of 1.0 mmol / g 3 ) 3 ·9H 2 In the O catalyst solution, ultrasonically vibrate for 1h, and the oscillation frequency is 20KHz;

[0056] S5, curing treatment, placing the solution obtained in step S4 in an oven, drying at 105° C. ...

Embodiment 3

[0060] Material Characterization and Property Determination

[0061] 1. Transmission electron microscope test

[0062] The samples were analyzed using high-resolution transmission electron microscopy.

[0063] The above-mentioned test is carried out to the graphitized porous carbon prepared by common activated carbon (coconut shell activated carbon), embodiment 1 and embodiment 2, and the results are as follows Figure 2-4 shown. figure 2 It is the transmission electron microscope image of ordinary coconut shell activated carbon, and its structure is more disordered; image 3 The transmission electron microscope image of the graphitized porous carbon prepared in Example 1 clearly shows the diffraction fringes of the 002 crystal plane of graphite, which changes to a layered structure and has a good degree of graphitization; Figure 4 For the TEM image of the graphitized porous carbon prepared in Example 2, it can be seen more clearly that the sample structure is transformed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com