Polyvinyl chloride and method for producing same

A technology of polyvinyl chloride and its manufacturing method, which is applied in the field of polyvinyl chloride and its manufacture, can solve the problems that monomers cannot be added to the reactor and cannot be applied to mass production processes, etc., so as to reduce surface roughness, increase false specific gravity, and reduce The effect of the amount of fine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

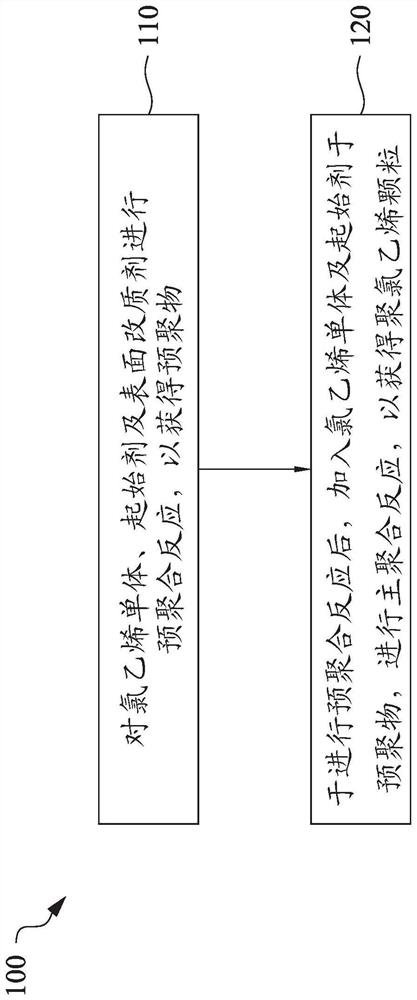

Method used

Image

Examples

Embodiment 1

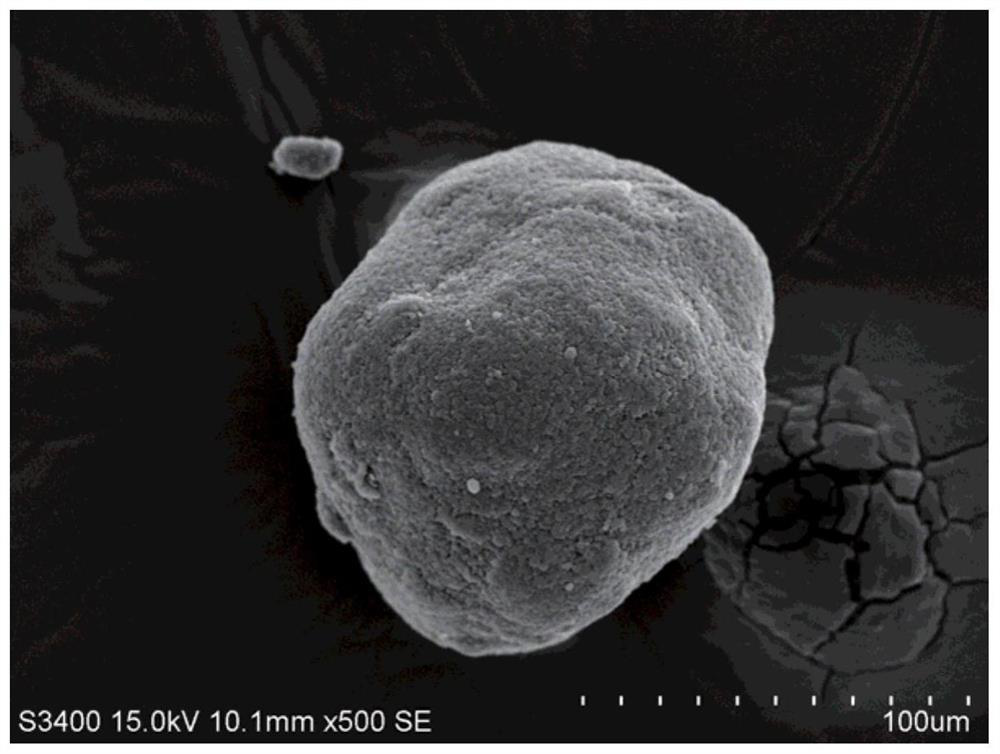

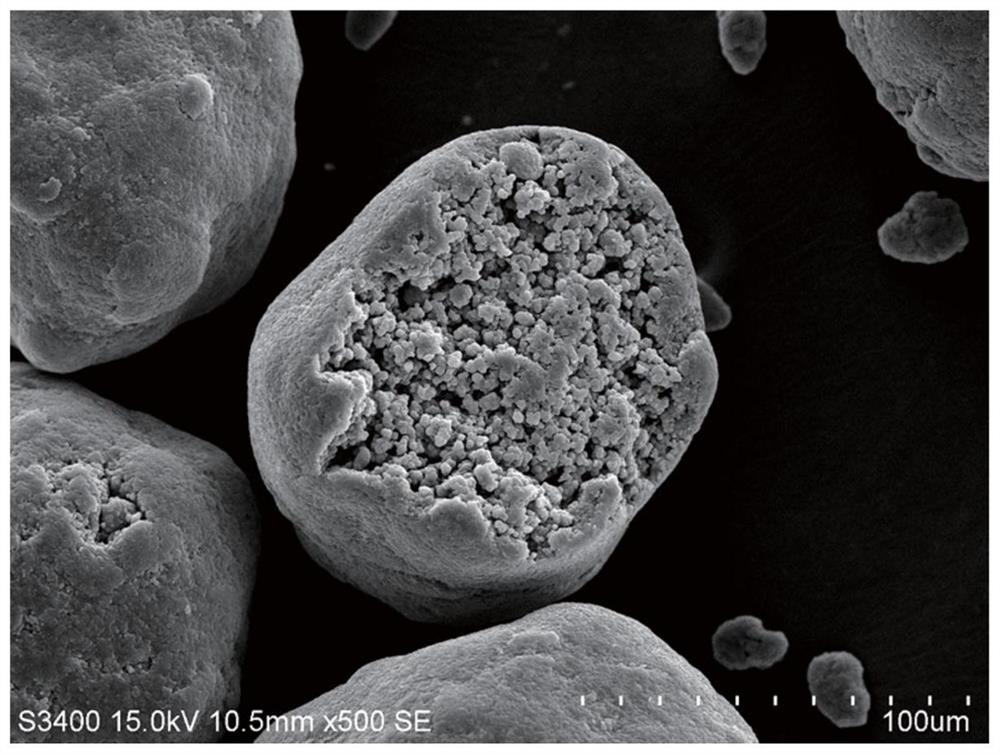

[0064] For the polyvinyl chloride in Example 1, 19 metric tons of vinyl chloride monomer, 9 kg of bis(2-ethylhexyl) peroxydicarbonate and 0.015 kg of Tween20 were added to the prepolymerization tank. When the reaction rate was 10%, the prepolymerization reaction was terminated to obtain a prepolymer. Then, the prepolymer is displaced in the main polymerization tank, and 14 metric tons of vinyl chloride monomer and 7 kg of peroxydicarbonate bis (2-ethylhexyl) ester and 5 kg of peroxy (trimethylacetic acid) tertiary Hexyl ester, carry out the main polymerization reaction, when the waiting reaction rate is 80%, terminate the main polymerization reaction. Then, unreacted vinyl chloride monomer was removed to obtain granular polyvinyl chloride of Example 1. These polyvinyl chloride particles were evaluated by the following evaluation methods, and the results are shown in Table 1.

Embodiment 2 to 3 and comparative example 1 to 5

[0066]The polyvinyl chlorides of Examples 2 to 3 and Comparative Examples 1 to 5 were all produced in a manner similar to that of Example 1. The difference is that in Examples 2 to 3 and Comparative Examples 1 to 5, the type and weight of the surface modifier were changed, and Tween20 in Example 3 was added to the main polymerization tank. The specific conditions and evaluation results are shown in Table 1 below.

[0067] Evaluation method

[0068] 1. Average particle size test

[0069] The average particle size test uses a shaking sieve machine (manufactured by SEISHIN, its model is RPS-205), and the average particle size of the polyvinyl chloride particles is measured by the sieving method and according to the American Society for Testing and Materials (ASTM) E11 standard method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com