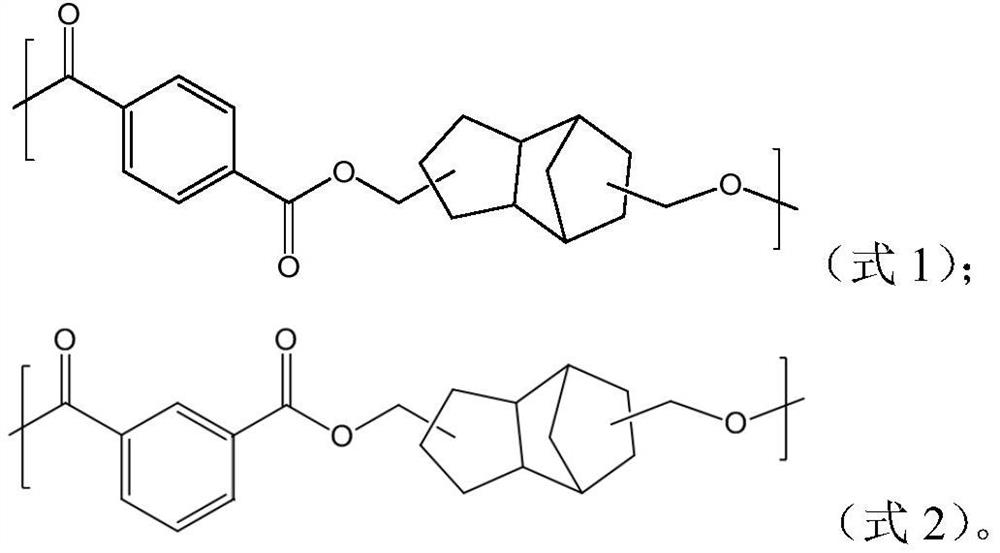

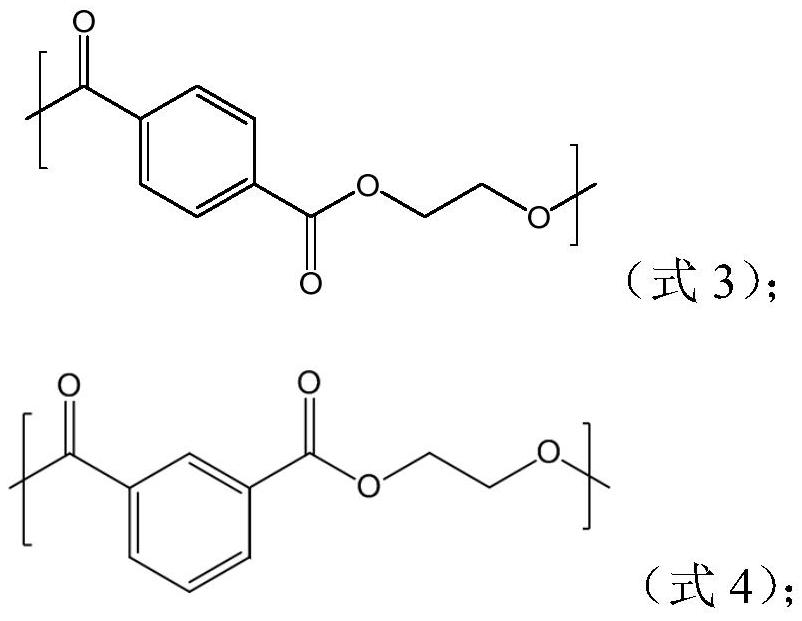

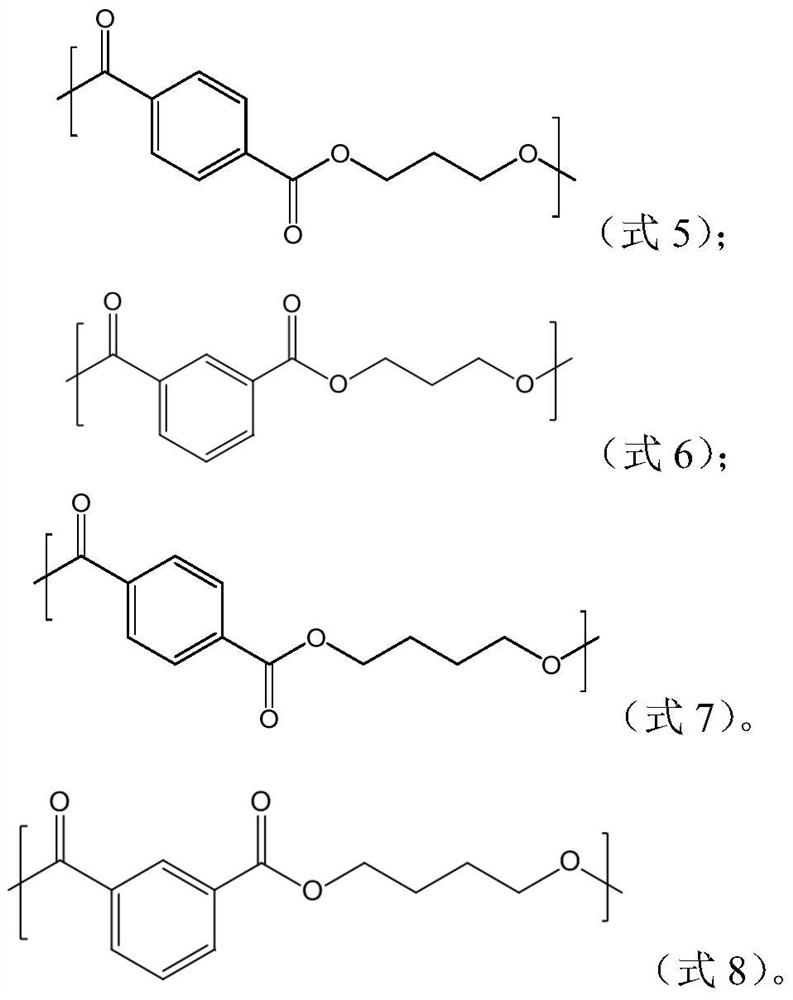

Toughness-enhanced transparent copolyester material and preparation method thereof

A copolyester, transparent technology, applied in the field of C08G, can solve the problems of reduced transparency, limited application scope, weakened toughness of PET polyester resin, etc., and achieves the effect of high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This example provides a kind of copolyester material, and the preparation raw material of described copolyester material is aromatic dibasic acid (TPA) with 1992g terephthalic acid, with 706g (accounting for 30mol% of aromatic dibasic acid) Tricyclodecane dimethanol, 409g (accounting for 55mol% of aromatic dibasic acid) of ethylene glycol and 410g (accounting for 45mol% of aromatic dibasic acid) of 1,3-propanediol are diols through esterification and polycondensation Obtain, add the n-butyl titanate that accounts for copolyester weight 200ppm before the esterification reaction as the main catalyst, add the cobalt acetate that accounts for copolyester weight 100ppm triphenyl phosphate and 70ppm before the polycondensation reaction as stabilizer and cocatalyst.

[0057] The preparation method of the copolyester material includes: mixing aromatic dibasic acid and diol, passing nitrogen to replace the air in the kettle, adding the main catalyst, raising the temperature to 2...

Embodiment 2

[0059] This example provides a kind of copolyester material, the preparation raw material of described copolyester material is the aromatic dibasic acid (TPA) with 1992g terephthalic acid, with 941g (accounting for 40mol% of aromatic dibasic acid) Tricyclodecane dimethanol, 409g (accounting for 55mol% of aromatic dibasic acid) of ethylene glycol and 319g (accounting for 35mol% of aromatic dibasic acid) of 1,3-propanediol are diols through esterification and polycondensation Obtain, add the n-butyl titanate that accounts for copolyester weight 200ppm before the esterification reaction as the main catalyst, add the cobalt acetate that accounts for copolyester weight 100ppm triphenyl phosphate and 70ppm before the polycondensation reaction as stabilizer and cocatalyst.

[0060] The preparation method of the copolyester material includes: mixing aromatic dibasic acid and diol, passing nitrogen to replace the air in the kettle, adding the main catalyst, raising the temperature to 2...

Embodiment 3

[0062] This example provides a kind of copolyester material, the preparation raw material of described copolyester material is the aromatic dibasic acid (TPA) with 1992g terephthalic acid, with 1410g (accounting for 60mol% of aromatic dibasic acid) Tricyclodecane dimethanol, 409g (accounting for 55mol% of aromatic dibasic acid) of ethylene glycol and 137g (accounting for 15mol% of aromatic dibasic acid) of 1,3-propanediol are diols through esterification and polycondensation Obtain, add the n-butyl titanate that accounts for copolyester weight 200ppm before the esterification reaction as the main catalyst, add the cobalt acetate that accounts for copolyester weight 100ppm triphenyl phosphate and 70ppm before the polycondensation reaction as stabilizer and cocatalyst.

[0063] The preparation method of the copolyester material includes: mixing aromatic dibasic acid and diol, passing nitrogen to replace the air in the kettle, adding the main catalyst, raising the temperature to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com