Extraction method of polylysine

A polylysine, extraction method technology, applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve problems such as limiting the development and application of polylysine, and achieve low extraction cost, purity and recovery. High rate and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

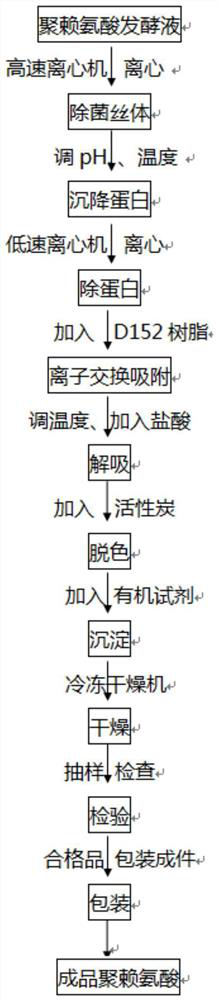

Image

Examples

Embodiment 1

[0040] 1. Take 1L of fermentation broth and centrifuge it at a speed of 8000r / min for 30min to remove mycelium.

[0041] 2. The supernatant was adjusted to pH 4.0, maintained at 65°C for 20 minutes, and centrifuged at 8000r / min for 20 minutes to remove protein flocs.

[0042] 3. The clarified fermented liquid obtained from pretreatment was ion-exchanged with weakly acidic cation exchange resin D152, wherein the adsorption pH was 7.5, the resin dosage was 160 g / L, the adsorption time was 15 hours, and the adsorption temperature was 25°C.

[0043] 5. After the resin is obtained by filtration, perform desorption. The desorption HCL concentration is 0.2 mol / L, the desorption time is 10 hours, and the desorption temperature is 30°C.

[0044] 6. Concentrate the ion-exchange solution 5 times, and then decolorize it with activated carbon, the decolorization pH is 4.0, the amount of activated carbon is 5%, and the decolorization is 75 minutes at 90°C.

[0045] 7. Filter paper to remov...

Embodiment 2

[0049] 1. Take 1L of fermentation broth and centrifuge it at a speed of 8000r / min for 30min to remove mycelium.

[0050] 2. The supernatant was adjusted to pH 4.0, maintained at 65°C for 20 minutes, and centrifuged at 8000r / min for 20 minutes to remove protein flocs.

[0051] 3. The clarified fermented liquid obtained from the pretreatment was ion-exchanged with weakly acidic cation exchange resin D152, wherein the adsorption pH was 8, the resin dosage was 150 g / L, the adsorption time was 10 h, and the adsorption temperature was 25°C.

[0052] 5. After the resin is obtained by filtration, perform desorption. The desorption HCL concentration is 0.2 mol / L, the desorption time is 10 hours, and the desorption temperature is 30°C.

[0053] 6. Concentrate the ion-exchange solution 5 times, and then decolorize it with activated carbon, the decolorization pH is 4.0, the amount of activated carbon is 5%, and the decolorization is 75 minutes at 90°C.

[0054] 7. Filter paper to remove ac...

Embodiment 3

[0058] 1. Centrifuge the fermentation broth at a speed of 8000r / min for 30min to remove the mycelium.

[0059] 2. The supernatant was adjusted to pH 4.0, maintained at 65°C for 20 minutes, and centrifuged at 8000r / min for 20 minutes to remove protein flocs.

[0060] 3. The clarified fermented liquid obtained from the pretreatment was ion-exchanged with weakly acidic cation exchange resin D152, wherein the adsorption pH was 7, the resin dosage was 180g / L, the adsorption time was 20h, and the adsorption temperature was 25°C.

[0061] 5. After the resin is obtained by filtration, perform desorption. The desorption HCL concentration is 0.2 mol / L, the desorption time is 10 hours, and the desorption temperature is 30°C.

[0062] 6. Concentrate the ion-exchange solution 5 times, and then decolorize it with activated carbon, the decolorization pH is 4.0, the amount of activated carbon is 5%, and the decolorization is 75 minutes at 90°C.

[0063] 7. Filter paper to remove activated ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com