Single-component addition type liquid silicone rubber

A liquid silicone rubber, addition-type technology, applied in the field of liquid silicone rubber, can solve the problems of wrinkling on the surface of sulfide and deterioration of storage performance, achieve high-efficiency inhibition effect, improve storage stability and smoothness of vulcanized surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

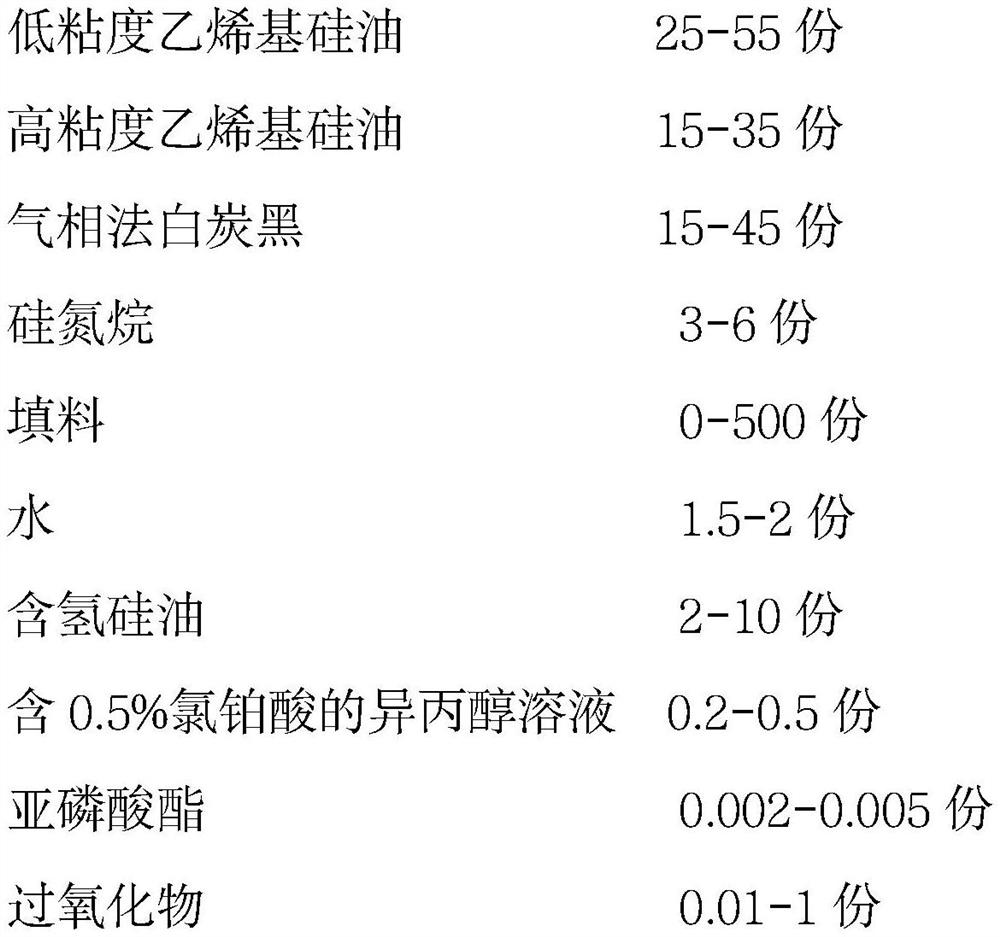

[0024] A one-component addition type liquid silicone rubber, according to parts by weight, includes the following components:

[0025]

[0026]

[0027] Low viscosity vinyl silicone oil has a viscosity of 200mPa.s, and high viscosity vinyl silicone oil has a viscosity of 7500mPa.s.

[0028] The phosphite is triphenyl phosphite.

[0029] Described peroxide is a kind of in double two four, two two five, hydroperoxide, is double two four in the present embodiment.

[0030] The mass fraction of hydrogen in the hydrogen-containing silicone oil is 0.1%.

[0031] The liquid silicone rubber of the above components is heated and fully cured at 120°C for 20 minutes, and heated at 150°C for 6 minutes. After curing, the surface is smooth, and the measured bonding strength with the substrate aluminum is 1.60 MPa; the storage time and viscosity changes at room temperature are shown in Table 1.

Embodiment 2

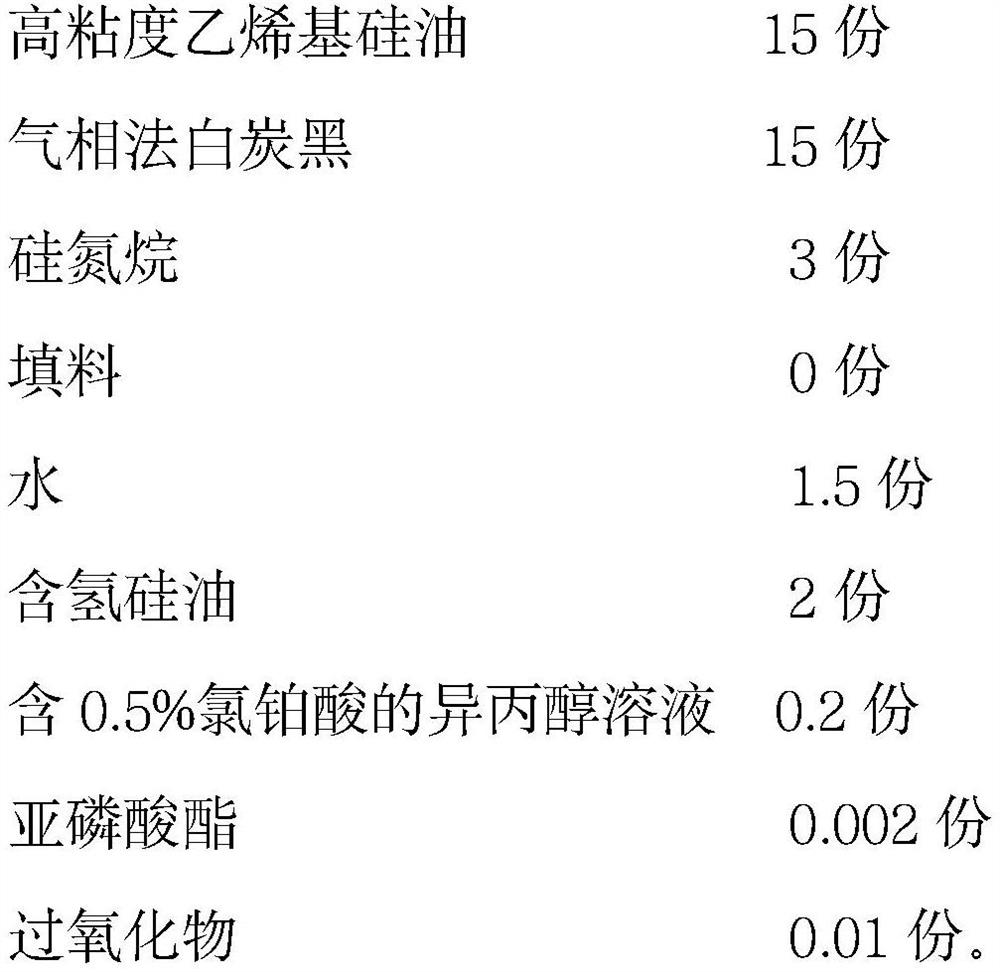

[0033] A one-component addition type liquid silicone rubber, according to parts by weight, includes the following components:

[0034]

[0035] The low-viscosity vinyl silicone oil has a viscosity of 500 mPa.s, and the high-viscosity vinyl silicone oil has a viscosity of 10000 mPa.s.

[0036] The phosphite is triphenyl phosphite.

[0037] The peroxide is bis-2-5.

[0038] The filler is alumina.

[0039] The mass fraction of hydrogen in the hydrogen-containing silicone oil is 0.4%.

[0040] The liquid silicone rubber of the above components is heated and fully cured at 120°C for 55 minutes, and heated at 150°C for 13 minutes. After curing, the surface is smooth, the measured bonding strength with the substrate aluminum is 2.03MPa, and the thermal conductivity is 0.9W / (K.m). The storage time and viscosity changes at room temperature are shown in Table 1.

Embodiment 3

[0042] A one-component addition type liquid silicone rubber, according to parts by weight, includes the following components:

[0043]

[0044] The low-viscosity vinyl silicone oil has a viscosity of 750 mPa.s, and the high-viscosity vinyl silicone oil has a viscosity of 20000 mPa.s.

[0045] The phosphite is triphenyl phosphite.

[0046] The peroxide is bis-diquat.

[0047] The fillers are aluminum nitride and boron nitride.

[0048] The mass fraction of hydrogen in the hydrogen-containing silicone oil is 0.6%.

[0049] The liquid silicone rubber of the above components is heated at 120°C for 15 minutes, and at 150°C for 5 minutes. After curing, the surface is smooth, the measured bonding strength with the substrate aluminum is 2.40MPa, and the thermal conductivity is 3.0W / (K.m). The storage time and viscosity changes at room temperature are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com