Tung oil-based aviation fuel anti-wear agent as well as preparation method and application thereof

A technology of aviation fuel and anti-wear agent, which is applied in the direction of fuel additives, fuel, carboxylate preparation, etc., can solve the problems of substandard anti-rust ability, achieve good anti-wear and water separation index, and avoid poor anti-rust performance The effect of reaching the target

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

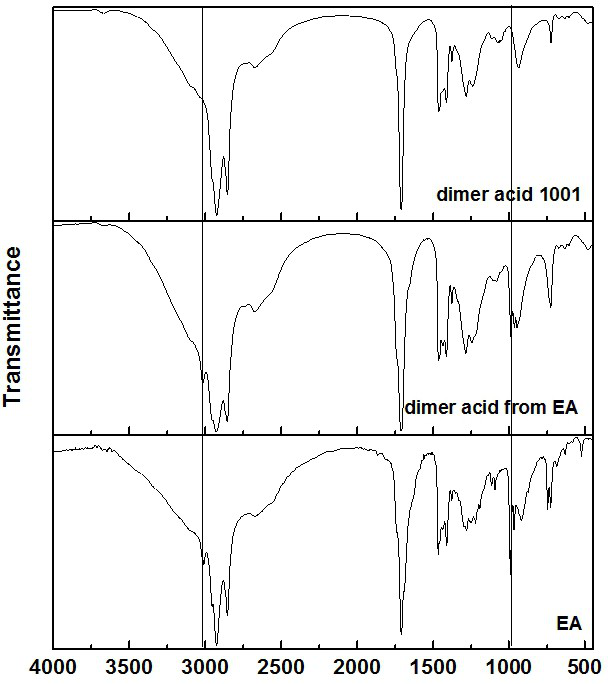

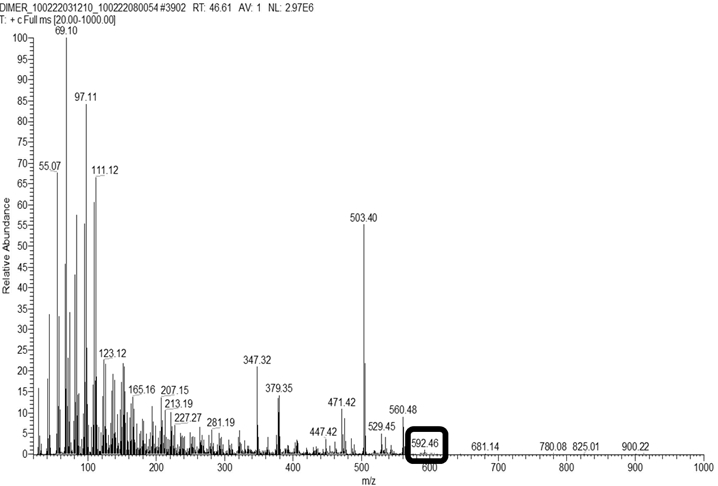

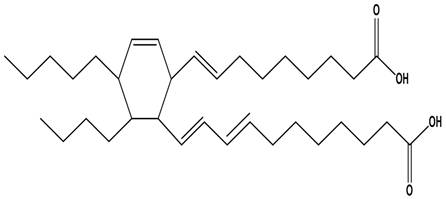

[0032]Adopt commercial tung oil acid, the iodine value of tung oil acid is 150g / 100g, and the acid value is 180mgKOH / g. Get 100g of commercial oleic acid and place it in a 250mL four-necked flask, add 0.5g hydroquinone and 0.25g regulator at the same time, the regulator is myristyl ammonium chloride and lithium carbonate, the mass ratio of the two is 1:1 , purged with nitrogen for 30 min, stirred at 300 rpm, and heated to 220° C. for 4 h. After the reaction was completed, it was cooled to room temperature in ice water to obtain a crude product. Two-stage molecular distillation is adopted, the distillation temperature of the first-stage molecular distillation is 150°C, the distillation pressure is ≤4Pa, and the speed of the scraping film is 400rpm. After the first-stage distillation, the monoacids that have not participated in the reaction are mainly removed; Two-stage molecular distillation, the distillation temperature is 150°C, the distillation pressure is ≤4Pa, and the rot...

Embodiment 2

[0035] Commercial tungoleic acid is adopted, the iodine value of tungoleic acid is 140g / 100g, and the acid value is 200mgKOH / g. Get 100 grams of commercial oleic acid and place it in a 250mL four-necked flask, add 0.25g hydroquinone and 1.0g regulator simultaneously, the regulator is cetyltrimethylammonium chloride and lithium carbonate, the mass ratio of the two The ratio was 2:1, nitrogen was purged for 30 minutes, the stirring rate was 300 rpm, and the temperature was raised to 230°C for 3 hours. After the reaction was completed, it was cooled to room temperature in ice water to obtain a crude product. Two-stage molecular distillation is adopted. The distillation temperature of the first-stage molecular distillation is 160°C, the distillation pressure is ≤4Pa, and the speed of the scraping film is 200rpm. After the first-stage distillation, the monoacids that have not participated in the reaction are mainly removed; Two-stage molecular distillation, the distillation temper...

Embodiment 3

[0037] Adopt commercial tung oil acid, the iodine value of tung oil acid is 160g / 100g, and the acid value is 150mgKOH / g. Get 100 grams of commercial oleic acid and place it in a 250mL four-necked flask, add 1.0g hydroquinone and 0.25g regulator simultaneously, the regulator is octadecyltrimethylammonium chloride and lithium carbonate, the mass ratio of the two The ratio was 3:1, nitrogen was purged for 30 minutes, the stirring rate was 300 rpm, and the temperature was raised to 200°C for 5 hours. After the reaction was completed, it was cooled to room temperature in ice water to obtain a crude product. Two-stage molecular distillation is adopted, the distillation temperature of the first-stage molecular distillation is 180°C, the distillation pressure is ≤4Pa, and the speed of the scraping film is 200rpm. After the first-stage distillation, the monoacids that have not participated in the reaction are mainly removed; Two-stage molecular distillation, the distillation temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com