Preparation and application of aflatoxin immunomagnetic beads

A technology of aflatoxin and magnetic absorption, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of a large number of organic reagents, time-consuming operation, environmental and operator damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method for aflatoxin immunomagnetic microspheres, comprising the steps of taking magnetic microspheres with active groups on the surface, washing 1-5 times with 0.1M pH 8.4 borax buffer solution, adding 1 mg of magnetic microspheres per mg %-10% antibody ratio, add aflatoxin antibody, mix well at 25°C, react for 1 hour, after the reaction, wash the magnetic microspheres with borax buffer to wash away unreacted aflatoxin Antibody; add 10% BSA, mix well at 4-40°C, react for 1-5 hours, after the reaction, wash the magnetic microspheres with 50mM pH7.4 phosphate buffer to obtain aflatoxin immunomagnetic microspheres ball. The immunomagnetic microspheres were stored in buffer until use.

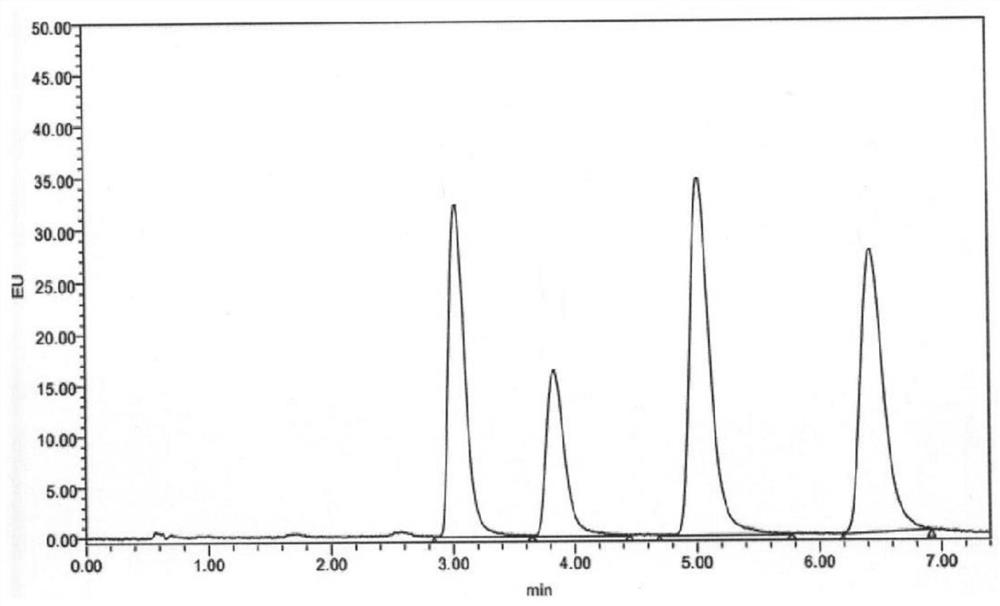

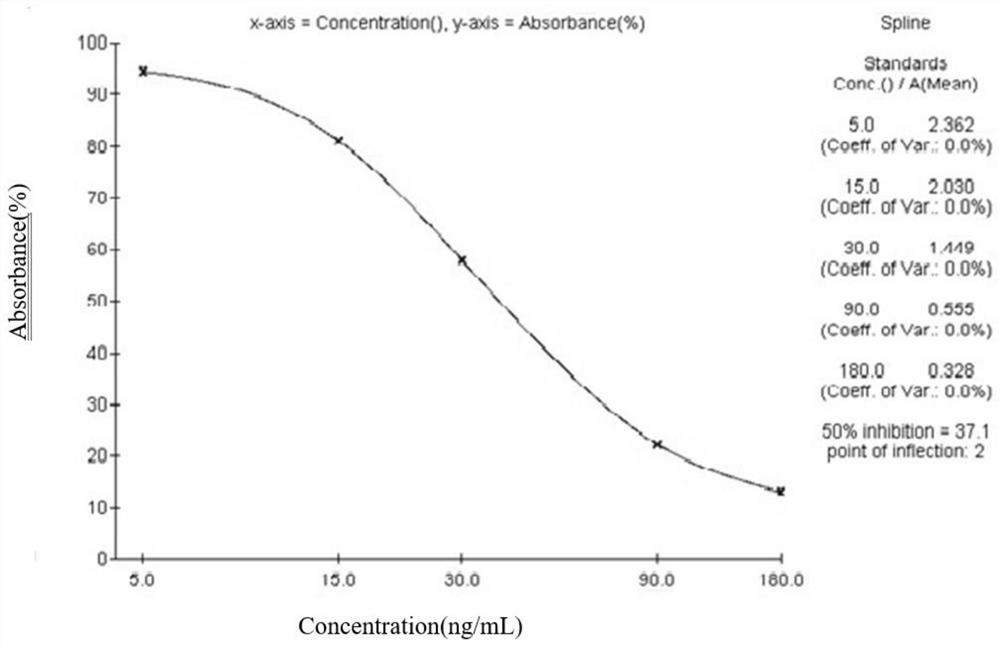

[0027] Its specific application is: pulverize calf feed with a pulverizer and pass it through a 5mm sampling sieve. Take 5g of the pulverized and sieved sample, add 20mL of 0.05M pH7.4 PBS buffer and mix well. Add 2 mg of aflatoxin immunomagnetic microspheres therein, and m...

Embodiment 2

[0029] A preparation method of aflatoxin immunomagnetic microspheres, comprising the steps of taking the magnetic microspheres with active groups on the surface, washing them twice with 0.05mM pH 6.0 citric acid buffer solution, and then dispersing the magnetic microspheres in the above-mentioned buffer in the liquid. According to the ratio of adding 1% antibody per mg of magnetic microspheres, add aflatoxin antibody, mix well at 4°C, and react for 17 hours. After the reaction, wash the magnetic microspheres with 0.05mM pH 6.0 citric acid buffer , to wash away unreacted aflatoxin antibodies; add 1mM ethanolamine solution, mix well at 37°C, and react for 1 hour. After the reaction, wash the magnetic microspheres with washing buffer to obtain aflatoxin immunomagnetic Microspheres. The immunomagnetic microspheres were stored in buffer until use.

[0030] Its specific application is: pulverize calf feed with a pulverizer and pass it through a 5mm sampling sieve. Take 5g of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com