Preparation method of flexible electrode of supercapacitor, flexible electrode and application thereof

A technology for supercapacitors and flexible electrodes, which is applied in the manufacture of hybrid capacitor electrodes, hybrid capacitor current collectors, and hybrid/electric double-layer capacitors. side issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific content of the present invention is further described below,

[0037] The invention discloses a method for manufacturing the flexible pole piece of a supercapacitor.

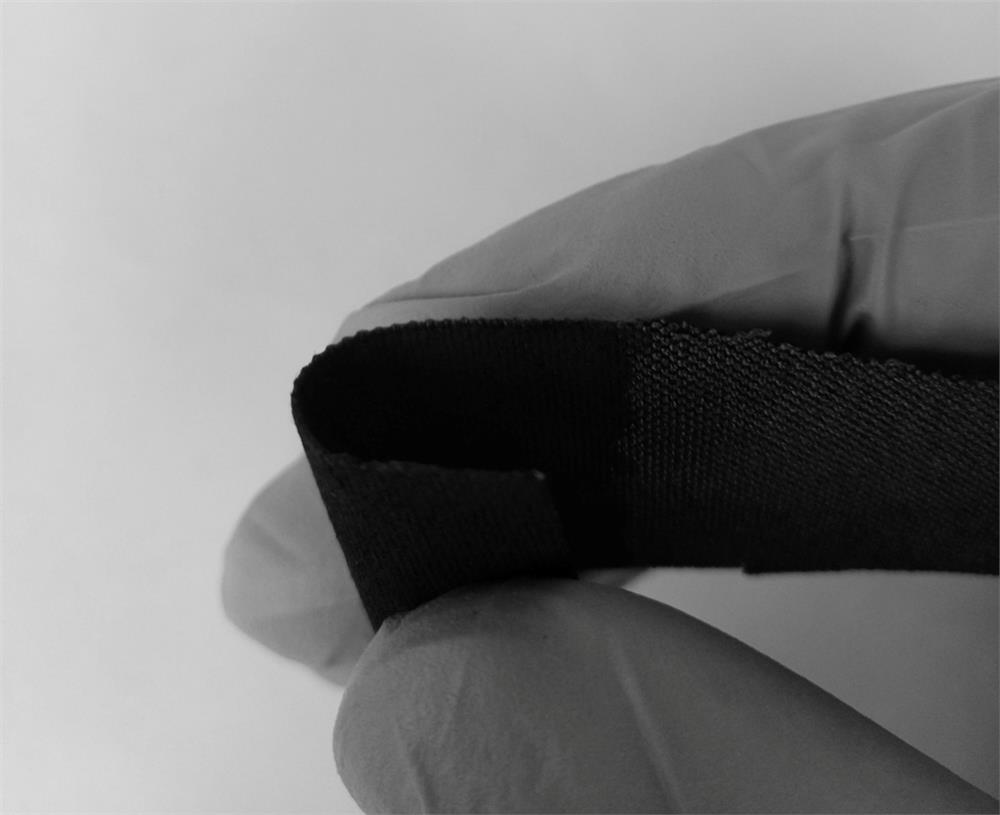

[0038] The flexible pole plate matrix of the supercapacitor of the present invention is a flexible carbon-based carrier, the flexible carbon-based carrier is carbon fiber cloth, and the surface of the matrix is coated with dried electrode slurry.

[0039] In the manufacturing method of the flexible pole piece of the present invention, the raw materials used in the present invention include activated carbon, conductive carbon, binder, carbon fiber cloth, deionized water, acetone, and ethanol.

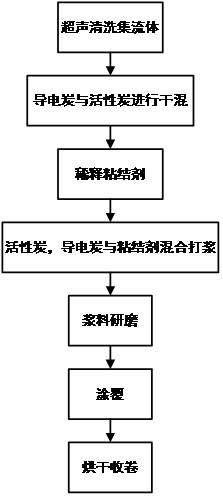

[0040] The flexible pole piece manufacturing method comprises the following steps:

[0041] 1) Clean and dry the carbon cloth;

[0042] 2) Dilute the binder to the required ratio;

[0043] 3) Stir and dry-mix activated carbon and conductive carbon;

[0044] 4) Mix the dry blend material and the bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com