Multilayer insole

A technology for insoles and fabric layers, applied in insoles, footwear, layered products, etc., can solve problems such as damage to the fabric layer, high cost, environmental pollution, etc., and achieve the effects of improving manufacturability and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

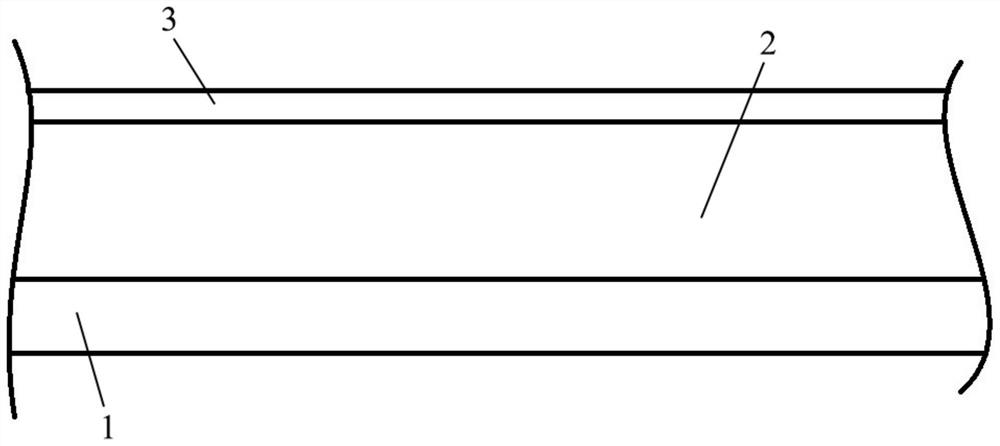

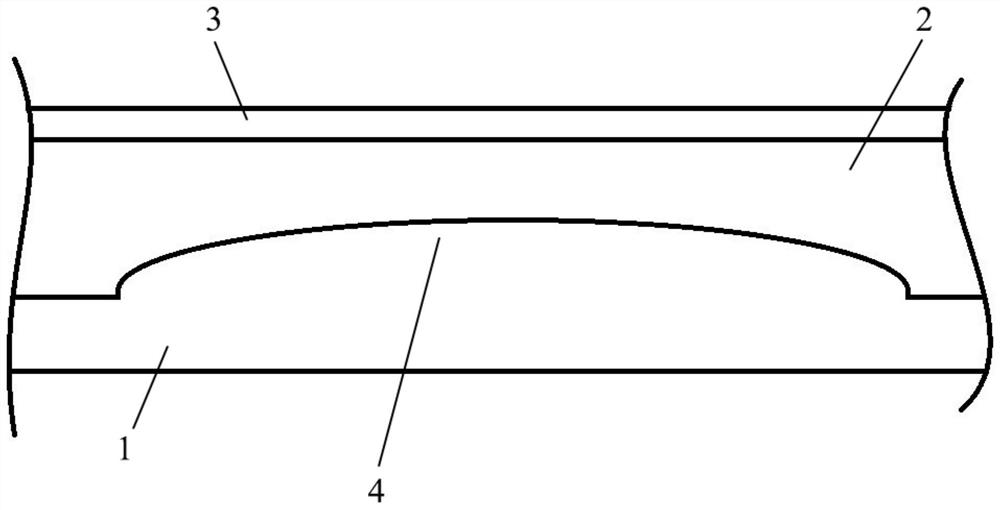

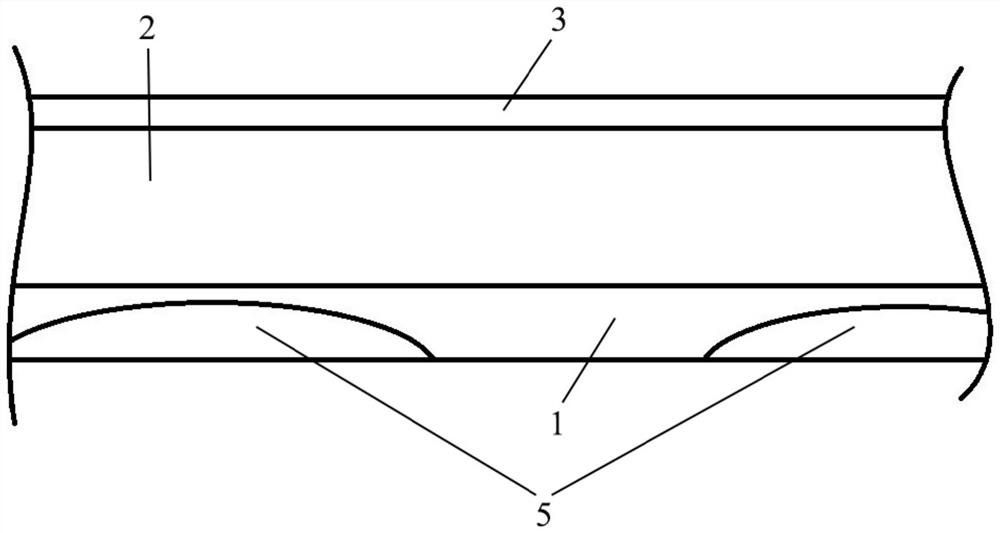

[0052] The drawings schematically show a preferred but not exclusive embodiment of the claimed multilayer insole comprising a base 1 , a foam layer 2 and a fabric layer 3 . Also in an embodiment, the claimed insole may comprise an elastic insert 5 joining the layer 4 and the base 1 .

[0053] The base 1 is made of rigid bio-based polyurethane that can be adhered to the inside of the sole and is necessary to form the structure of the claimed insole and to give it a stable shape. The rigid bio-based polyurethane substrate 1 can be eg bio-based polyurethane Pearlbond ECO (also known as Lubrizol), Renuva manufactured by Dow Chemicals, JEFFADD manufactured by Huntsman, Recypol, Econykol manufactured by Mitsui Chemicals & SKC Polyurethanes.

[0054] In a preferred embodiment of the claimed insole, the base 1 comprises at least one elastic insert 5 made of a bio-based polymer and which can be adhered to the inner side of the sole. The biobased polymer of the elastic insert 5 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com