Energy-consumption-free self-adaptive temperature control coating material as well as preparation method and application thereof

A coating material and self-adaptive technology, applied in coatings, heat-sensitive coatings, reflective/signal coatings, etc., can solve problems such as energy consumption, lack of induction and spontaneous regulation, and lack of automatic switching of cooling/heat preservation functions, etc. Achieve the effect of enhanced reflectivity and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

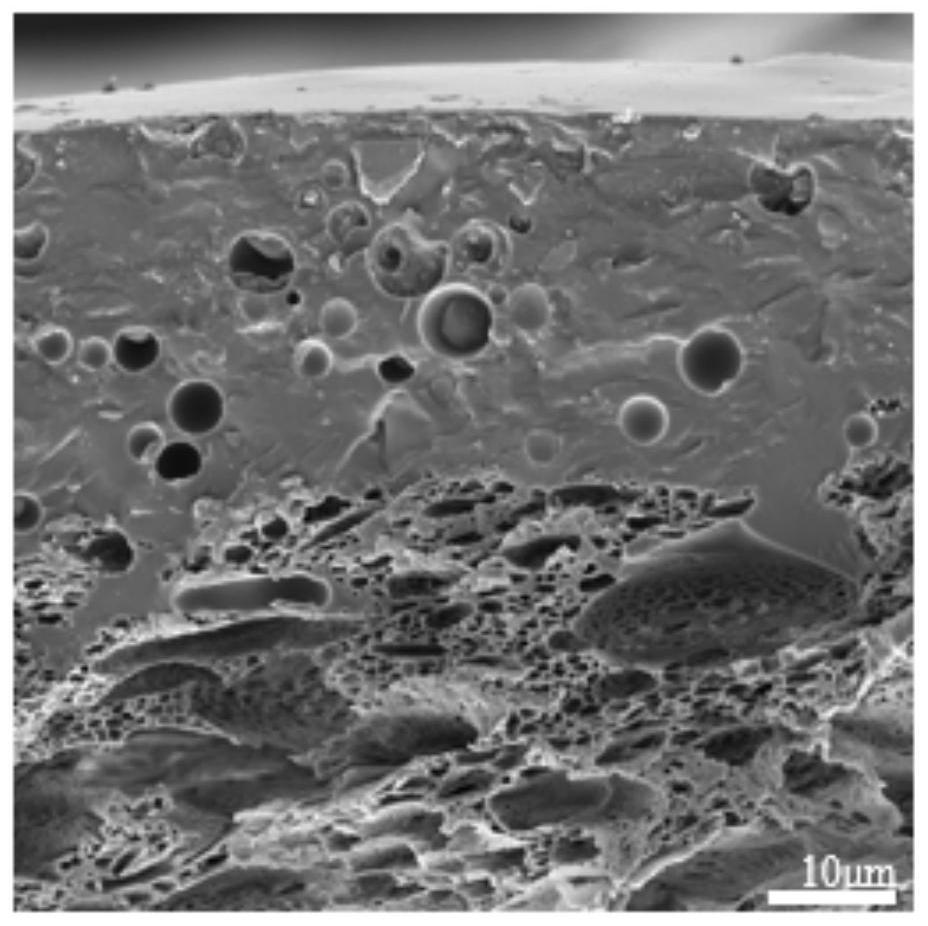

[0055]A non-energy self-adaptive temperature control coating material, with a spectrally selective porous film as the bottom layer, a thermochromic film on the spectrally selective porous film, and an anti-light fatigue film on the thermochromic film, in which the spectrally selective The porous film is a polymer porous film, the thermochromic film is a thermochromic microcapsule film, and the anti-light fatigue film is prepared by curing a UV absorber and a hindered amine light stabilizer. The mass ratio of the stabilizer is 1:1.

[0056] In this embodiment, the ultraviolet absorber is Tinuvin 1130, the hindered amine light stabilizer is Tinuvin 622SF, and the thickness of the anti-light fatigue film is 20 μm.

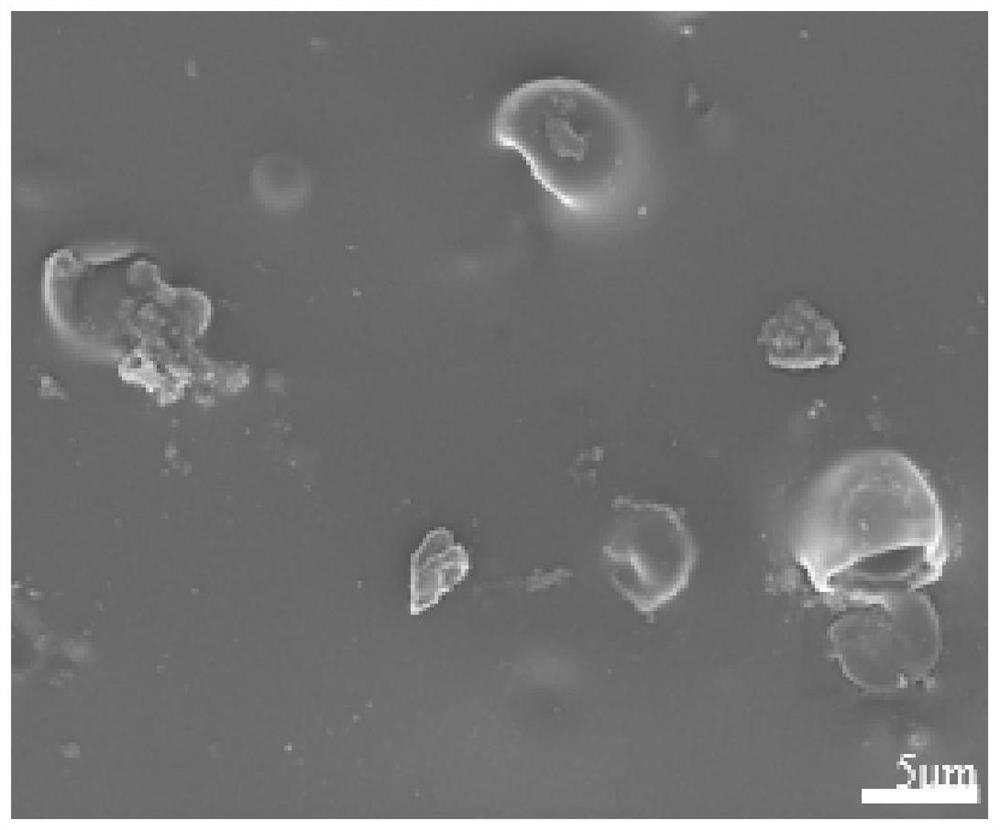

[0057] In this embodiment, the spectrally selective porous film is a polymer porous film, which is formed by stacking polymer porous films with a thickness of 280 μm; The peak distribution and the wide distribution are 0.2μm~0.6μm and 2μm~4.2μm respectively, and the ...

Embodiment 2

[0078] A method for preparing a self-adaptive temperature-control coating material without energy consumption, the steps are basically the same as in Example 1, the only difference is that in step (2), the mass ratio of thermochromic microcapsules to polymer is 1:20.

[0079] After testing, the solar reflectance of the energy-free self-adaptive temperature-control coating material in the colored state and the colorless state are 78.48% and 94.63% respectively, and the variation range reaches 16.15%.

Embodiment 3

[0081]A method for preparing a self-adaptive temperature-controlling coating material without energy consumption, the steps are basically the same as in Example 1, the only difference is that in step (2), the mass ratio of thermochromic microcapsules to polymer is 3:20.

[0082] After testing, the solar reflectance of the non-energy self-adaptive temperature control coating material in the colored state and the colorless state are 72.41% and 93.86% respectively, and the variation range reaches 21.45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com