Stress luminescent material and preparation and application thereof

A stress luminescence, material composition technology, applied in luminescent materials, textiles and papermaking, chemical instruments and methods, etc., can solve problems such as poor luminescence performance and inability to continuously prepare, achieve fast response speed, improve practical application value, and achieve The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

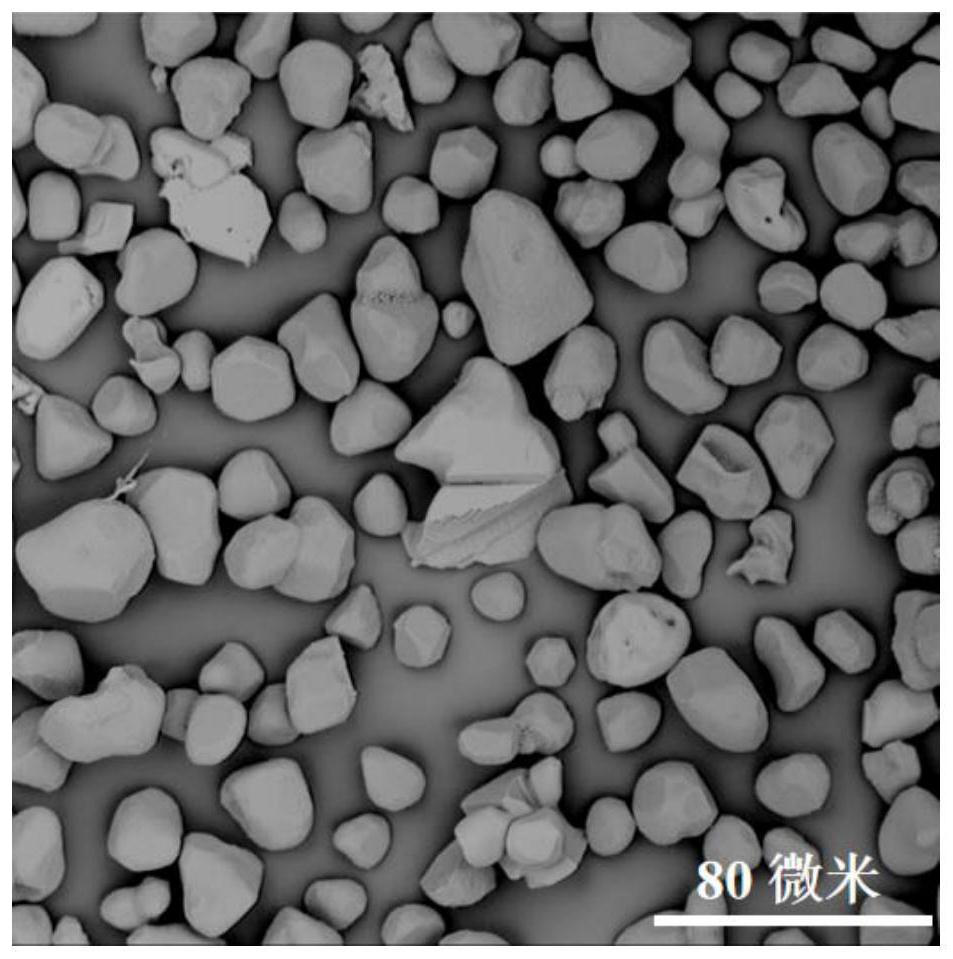

[0054] (1) Firing stress luminous powder

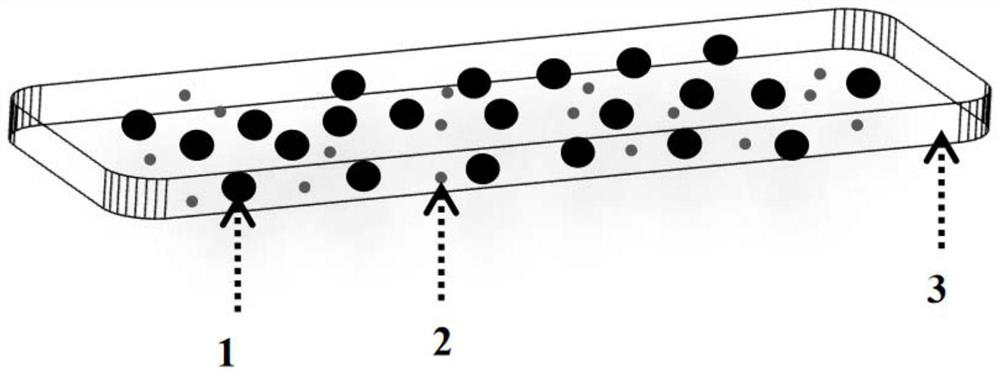

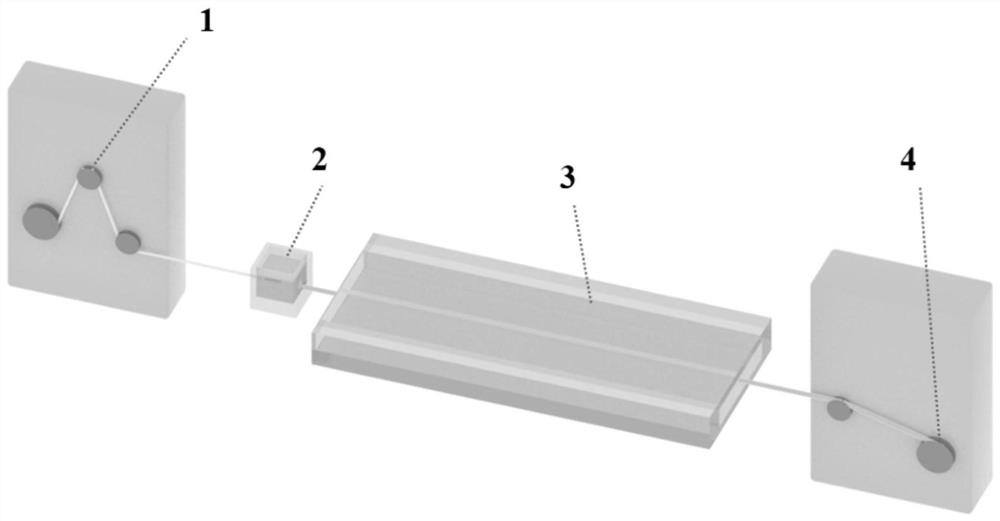

[0055] A high-temperature solid-phase method is used to sinter copper-containing zinc sulfide-based stress luminescent powder. Burning powder parameters: Weigh 400g of zinc sulfide raw material, additives include: copper sulfate powder 0.656g, sodium chloride solid 24g, magnesium chloride solid 40g, dissolve the additive in 200ml deionized water, stir to dissolve; add the additive solution and zinc sulfide raw material fully Mixing; place in an oven to dry, the drying condition is temperature 100°C, time 8h. After drying, it is calcined in a muffle furnace at 1100°C for 3 hours; after the reaction, the powder is quickly taken out, and after cooling at room temperature, the powder is cleaned with high-temperature deionized water, and the upper layer is removed after soaking the powder in deionized water for 30 minutes Liquid, repeated 5 times to remove excess impurities; after cleaning, put it in an oven and dry at 100°C for 4 hours. ...

Embodiment 2

[0064] Weigh 10g of the ZnS:Cu stress luminescent powder prepared in Example 1, 3g of 10nm silica particles, and 20g of silica gel, and mix the above materials thoroughly; place them in a vacuum oven for pre-curing and defoaming treatment, and the temperature is 60°C , and the temperature was 5 minutes to obtain a stress-luminescent slurry; according to steps (3) and (4) in Example 1, a stress-luminescent fabric was prepared.

Embodiment 3

[0066] Weigh 10g of the ZnS:Cu stress luminescent powder prepared in Example 1, 3g of 10nm alumina particles, and 20g of silica gel, and mix the above materials thoroughly; place them in a vacuum oven for pre-curing and defoaming treatment, the temperature is 60°C, The temperature was 5 minutes to obtain the stress-luminescent slurry; according to the steps (3) and (4) in Example 1, the stress-luminescent fabric was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com