Horizontal continuous copper alloy bar casting equipment and technological process

A technology for casting copper alloy and horizontal continuous casting is applied in the field of devices for horizontal continuous casting of copper alloy bars, which can solve the problems of lower productivity, lower bar quality, high power consumption, etc., so as to reduce production costs and reduce labor intensity. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

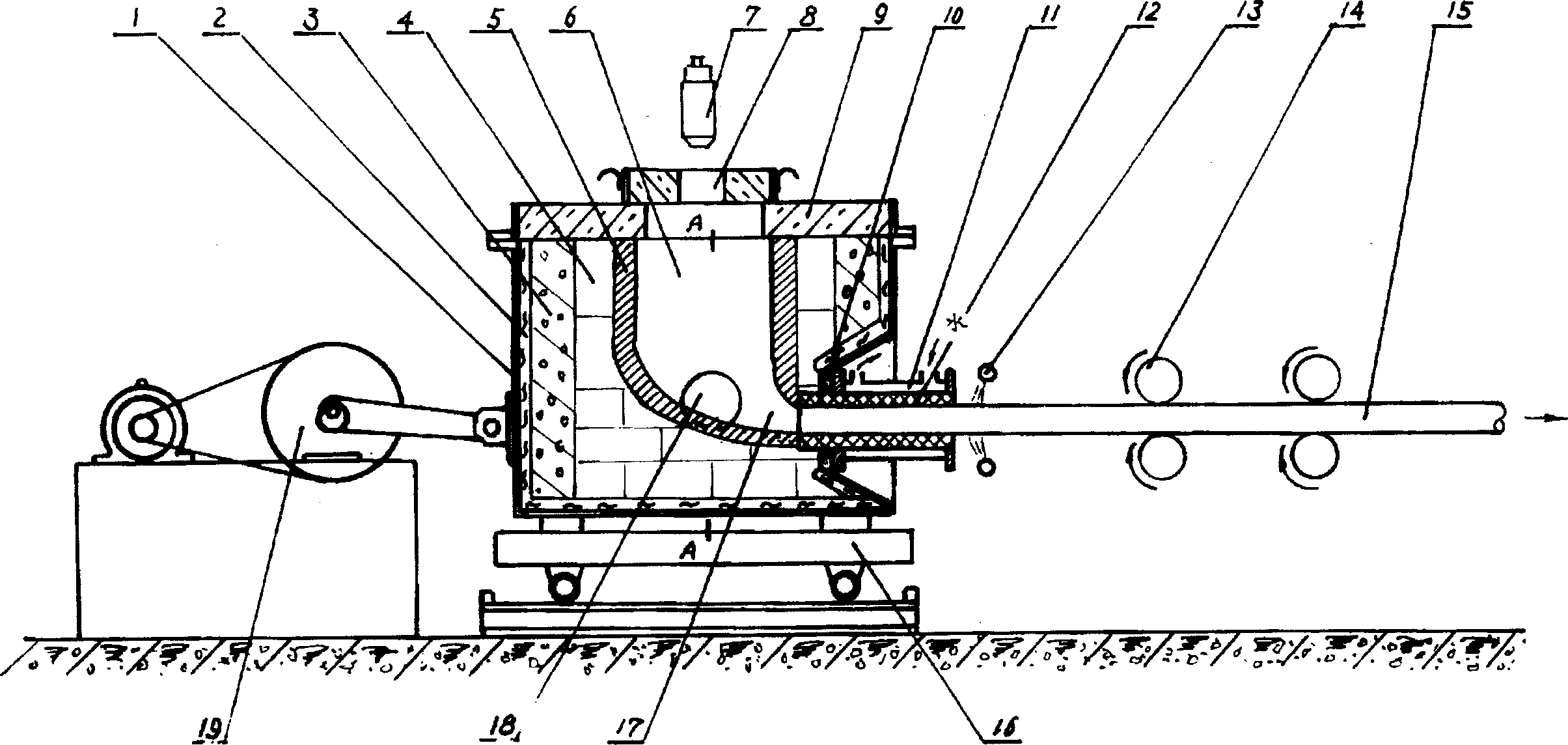

[0026] Example 1 A φ50 mm Cu-0.8% Cr copper-chromium alloy bar was drawn and cast.

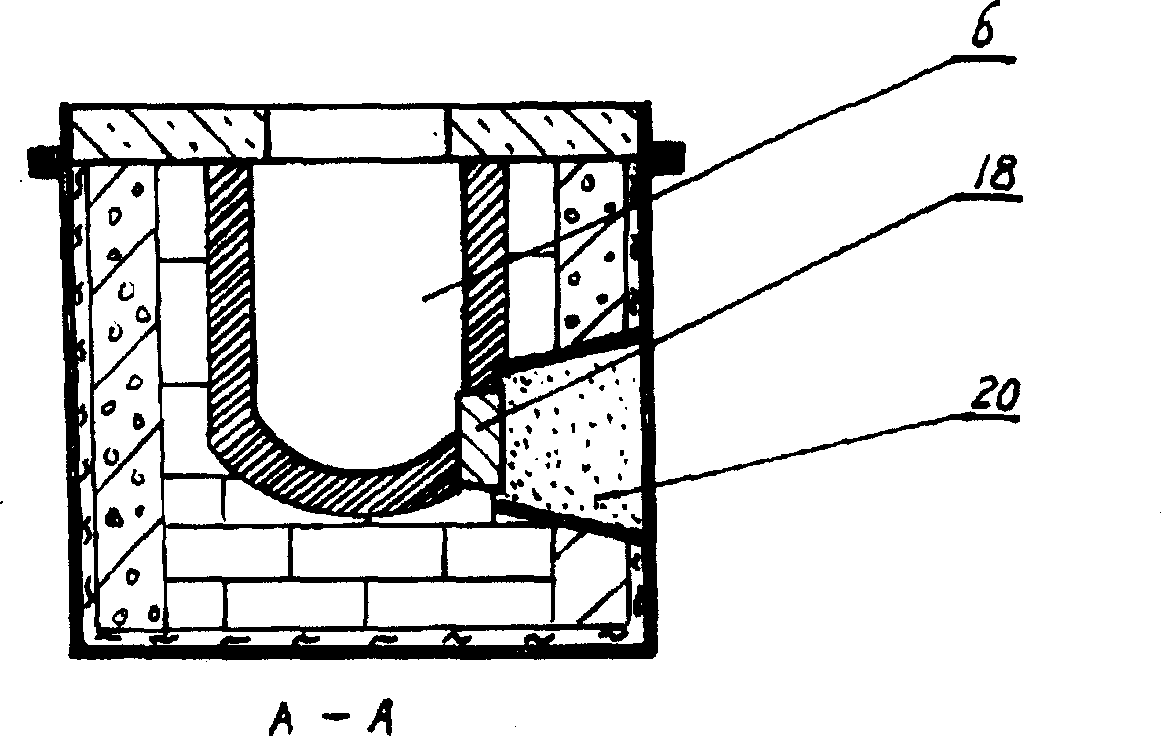

[0027] The inner lining is knotted into a cylinder with red silica powder clay mixture, the thickness is 50mm; the inner cavity is the inner chamber of the insulation bag, and the inner chamber size is 250mm in diameter and 300mm in height; the specific gravity of the insulation layer is 1g / cm 3 Lightweight refractory silica bricks with a thickness of 125mm; the inner insulation layer is made of diatomite bricks with a thickness of 100mm, and the corners of the insulation package are filled with diatomite bricks; the outer insulation layer is 20mm thick Aluminum silicate fiberboard; the outer shell is welded with 8mm steel plate; the bottom of the inner chamber is slope-shaped, inclined to the channel connecting the crystallizer, and the channel is in the shape of a small trumpet inside and outside; the operation hole is at the lower part of the side wall of the insulation package, under Along...

Embodiment 2

[0034] Example 2 A ZQSn6-6-3 tin bronze rod with a diameter of 55mm was drawn and cast using the above equipment.

[0035] (1) Remove the crystallizer, expand the graphite-type inner hole to 56.1mm; remove the operation hole block, and clean the inner bore;

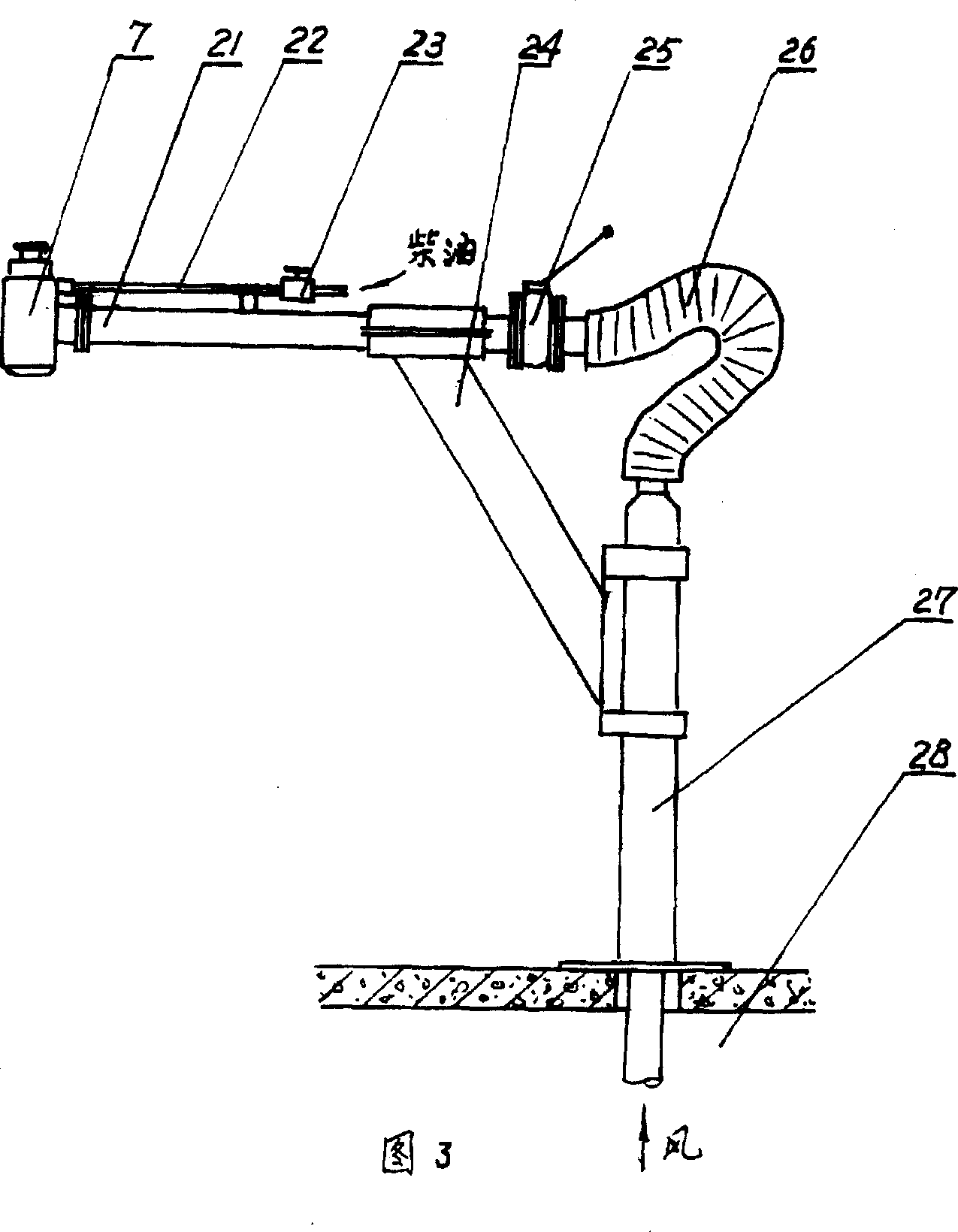

[0036] (2) Ignite the coke placed in the inner chamber of the insulation bag, preheat the inner chamber, and when the temperature of the inner chamber rises to 750°C, take out the coke from the operation hole, seal the operation hole with the operation hole block and fill it with sand Serious;

[0037] (3) Install the crystallizer on the channel port through the flange;

[0038] (4) Ignite the diesel heater, heat the inner chamber with a diesel flame, and when the temperature of the inner chamber rises to 1050°C, remove the nozzle of the diesel heater, and inject the first batch of ZQSn6-6-3 tin bronze melt from the liquid injection port ;

[0039] (5) Start the swing mechanism, and the traction mechanism pulls and cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com