Boron-doped nano polycrystalline diamond taking nano graphite as carbon source and preparation method of boron-doped nano polycrystalline diamond

A technology of polycrystalline diamond and nano-graphite, which is applied in the field of high-precision machining and cutting, and high-precision cutting abrasives, can solve the problems that the reaction mechanism has not been fully explained, and achieve the goal of changing surface activity, excellent cutting materials, and improving toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

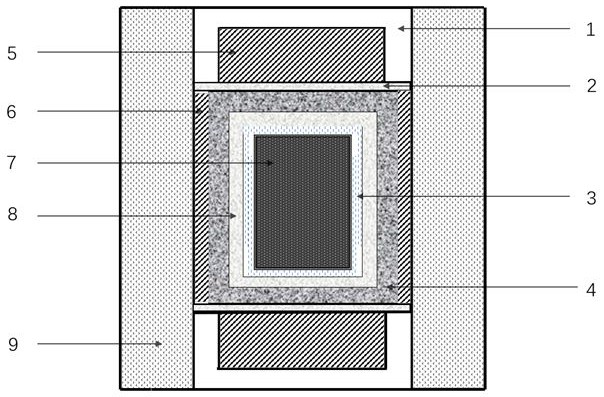

[0026] A kind of preparation method of the boron-doped nano-polycrystalline diamond of carbon source as carbon source comprises the following steps:

[0027] 1) Nano-graphite is subjected to surface purification treatment, followed by high-temperature and high-pressure sintering. The obtained material has high strength and wear resistance; The concentration is 3mol / L dilute sulfuric acid in the solution prepared according to the ratio of 1:3, stir, let stand for a period of time, rinse with deionized water until neutral, dry and put it in a dry container for later use;

[0028] 2) Weigh the mass fraction of 80-90wt% nano-graphite and 15-20wt% nano-boron obtained in step 1), and add polyvinylpyrrolidone dispersant to nano-graphite and nano-boron respectively and disperse them in ethanol by ultrasonic , remove the solvent, and fully dry to obtain dispersed nano-graphite and nano-boron. Mix the treated nano-graphite and nano-boron evenly under a high-energy ball mill. The ball m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com