Fly ash stabilizing treatment process after household garbage incineration

A domestic waste incineration and stabilization treatment technology, which is applied to chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of many factors in normal production, high operating costs, and many mechanical facilities, and achieve dissolution The efficiency is small, the operation cost is reduced, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

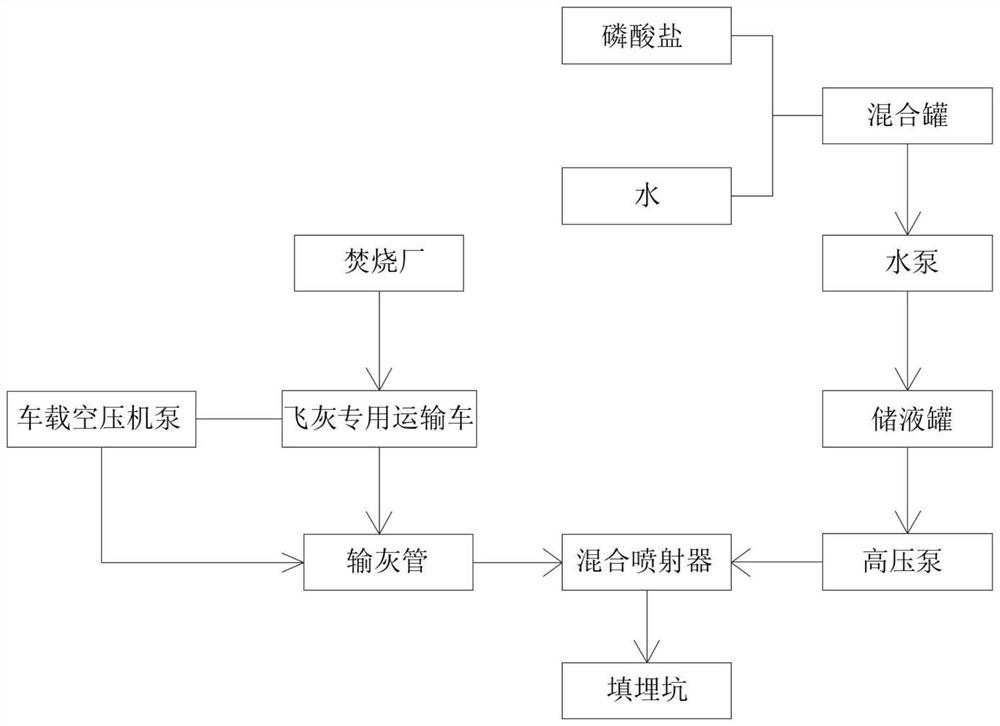

[0025] An embodiment of the present invention provides a process for stabilizing fly ash after domestic waste incineration, including the following processing steps:

[0026] S1. First excavate the landfill unit pool, each landfill unit pool is a square with a side length of 7m, and the height of the landfill unit pool is 5m, then pour a cement layer inside the landfill unit, and place Lay and fix the anti-leakage plastic film. After laying the anti-leakage plastic film, check whether there is any damaged part, and repair the damaged part in time to ensure the integrity of the anti-leakage plastic film;

[0027] S2. Then put the fly ash from the incineration plant into the tank of the special transport vehicle for fly ash. Air curtains are used at the inlet and outlet of the fly ash in the incineration plant to prevent the foul smell of fly ash from escaping. After the fly ash is loaded, it is directly transported to the step The landfill unit pool excavated by S1;

[0028] S...

Embodiment 2

[0039] An embodiment of the present invention provides a process for stabilizing fly ash after domestic waste incineration, including the following processing steps:

[0040] S1. First excavate the landfill unit pool. Each landfill unit pool is a square with a side length of 7.5m, and the height of the landfill unit pool is 5.5m. Lay and fix the anti-leakage plastic film on the layer. After the anti-leakage plastic film is laid, check whether there is any damaged part, and repair the damaged part in time to ensure the integrity of the anti-leakage plastic film;

[0041] S2. Then put the fly ash from the incineration plant into the tank of the special transport vehicle for fly ash. Air curtains are used at the inlet and outlet of the fly ash in the incineration plant to prevent the foul smell of fly ash from escaping. After the fly ash is loaded, it is directly transported to the step The landfill unit pool excavated by S1;

[0042] S3. Phosphate hydrochloric acid and water ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com